Content .. 1328 1329 1330 1331 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1330

6E1–396

RODEO Y22SE 2.2L ENGINE DRIVEABILITY AND EMISSION

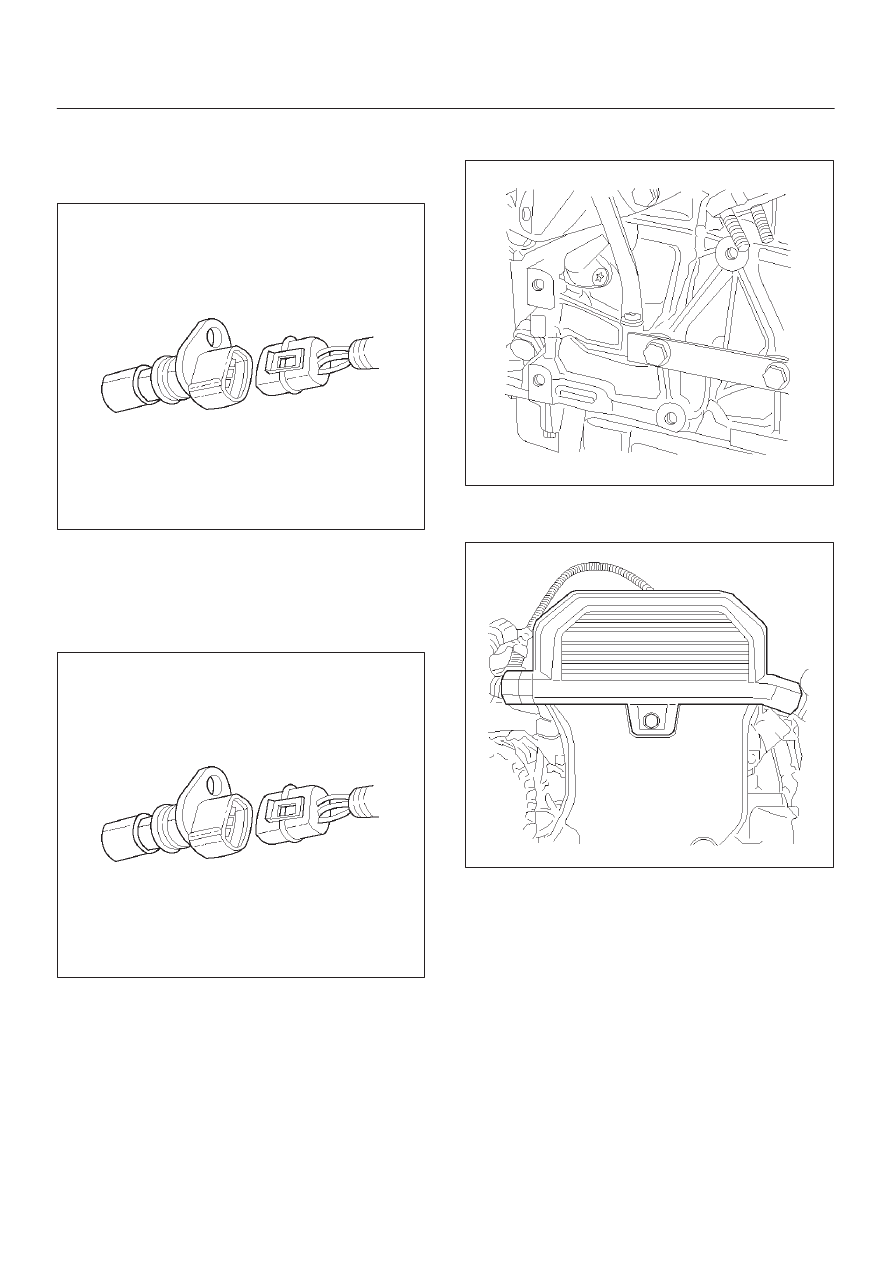

5. Remove the retaining bolt and sensor from the engine

block.

NOTE: Use caution to avoid any hot oil that might drip

out.

0013

Installation Procedure

1. Install the crank shaft position sensor to its position.

2. Install and tighten the mounting bolt. Refer to Engine

Mechanical Section.

0013

3. Reinstall the power steering pump and bracket to the

engine.

014RX006

4. Reinstall the accessory drive belt.

5. Connect the negative battery cable.

014RX003

IMPORTANT:

PCM must re–learn Crankshaft Position

when the CKP sensor is replaced. Refer to CKP sensor

learn mode on the Tech 2, or Tooth Error Correction in the

Service Manual.