Content .. 1221 1222 1223 1224 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1223

6C–4

ENGINE FUEL (Y22SE 2.2L)

Fuel Filter

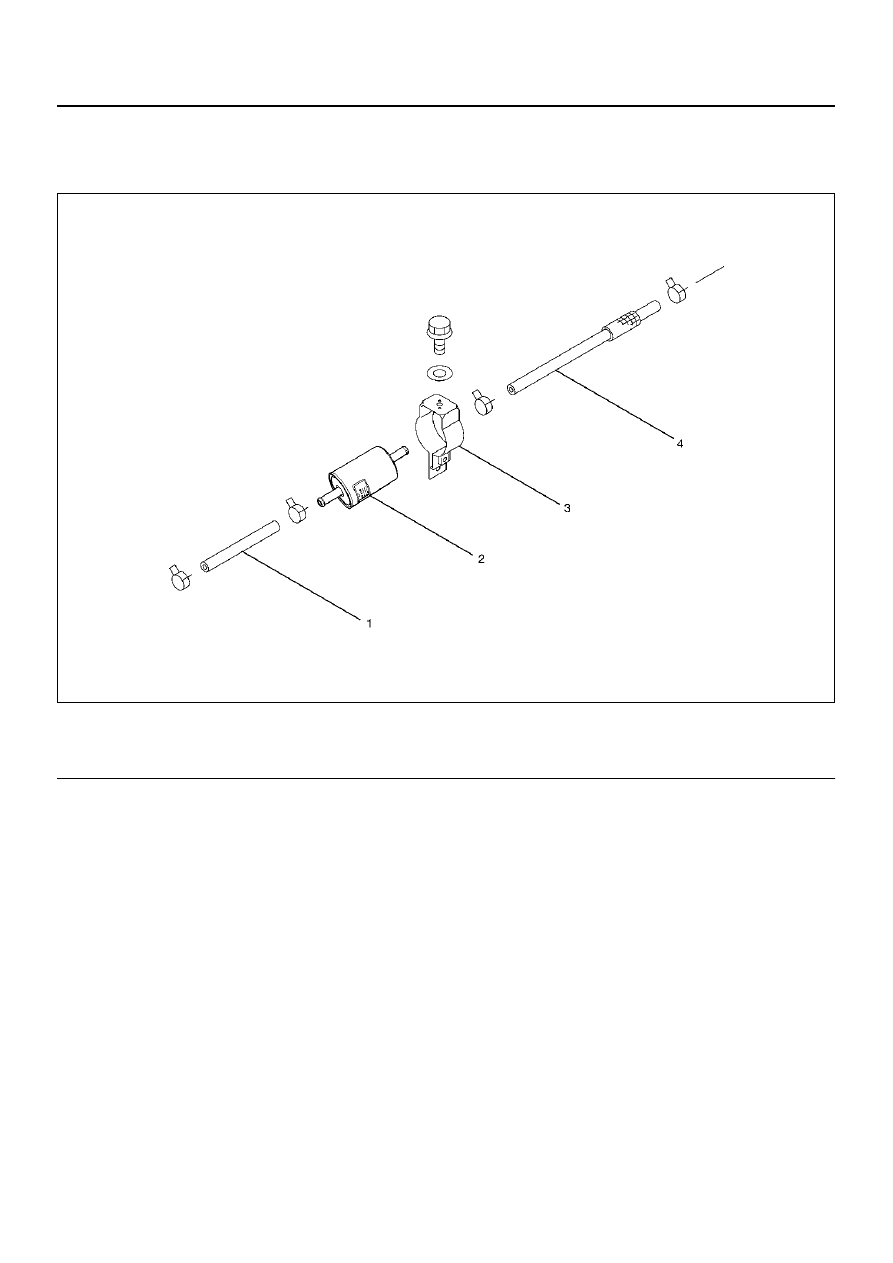

Fuel Filter and Associated Parts

140R100007

EndOFCallout

Removal

CAUTION: When repair to the fuel system has been

completed, start engine and check the fuel system

for loose connections or leakage. For the fuel

system diagnosis, see Section “Driveability and

Emission”.

1. Disconnect battery ground cable.

Legend

(1) Fuel Hose

(2) Fuel Filter

(3) Fuel Filter Holder

(4) Fuel Hose