Content .. 1214 1215 1216 1217 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1216

6A–61

ENGINE MECHANICAL (Y22SE 2.2L)

Inspection and Repair

1. Inspect the cylinder head gasket and any other

material adhering to the upper surface of the cylinder

block.

CAUTION: Be very careful not to allow any material

to accidentally drop into the cylinder block. Be very

careful not to scratch the cylinder block.

2. Carefully inspect the oil pump, rear oil seal retainer,

and crankcase assembly installation surface seal.

3. Wipe the cylinder block clean.

4. Visually inspect the cylinder block. If necessary, use a

flaw detector to perform a dye penetrate and

hydraulic (or air pressure) test. If cracking or other

damage is discovered, the cylinder block must either

be repaired or replaced.

Flatness

1. Using a straight edge and feeler gauge, check that the

upper surface of the cylinder block is not warped.

CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

2. After re-grinding cylinder block maximum piston

protrusion 0.4 mm (0.0157 in).

012RW013

Cylinder Bore

Use a cylinder gauge to measure the cylinder bore

diameter in both the axial and thrust directions. Each

measurement should be made at six points.

CAUTION: Be very careful not to allow any material

to accidentally drop into the upper surface of the

cylinder block. Be very careful not to scratch the

upper surface of the cylinder block.

If the measurement exceeds the specified limit, the

cylinder block must be replaced.

Grade

number

Cylinder bore

99

85.985 – 85.995 mm

(3.3852 – 3.3856 in)

00

85.995 – 86.005 mm

(3.3856 – 3.3860 in)

O/S 0.5

86.495 – 86.505 mm

(3.4053 – 3.4057 in)

NOTE: For information on piston diameter, please refer

to the section “Inspection and repair of the Piston and

Connecting Rod” in this manual.

Reassembly

1. Cylinder block.

2. Install crankshaft.

D

Install the main bearings to the cylinder block and

the main bearing caps.

Apply liquid gasket to rear bearing cap in slots

provided.

D

Be sure that they are positioned correctly.

D

Apply new engine oil to the upper and lower main

bearing faces.

NOTE: Do not apply engine oil to the bearing back faces.

D

Carefully mount the crankshaft.

D

Apply engine oil to the thrust washer.

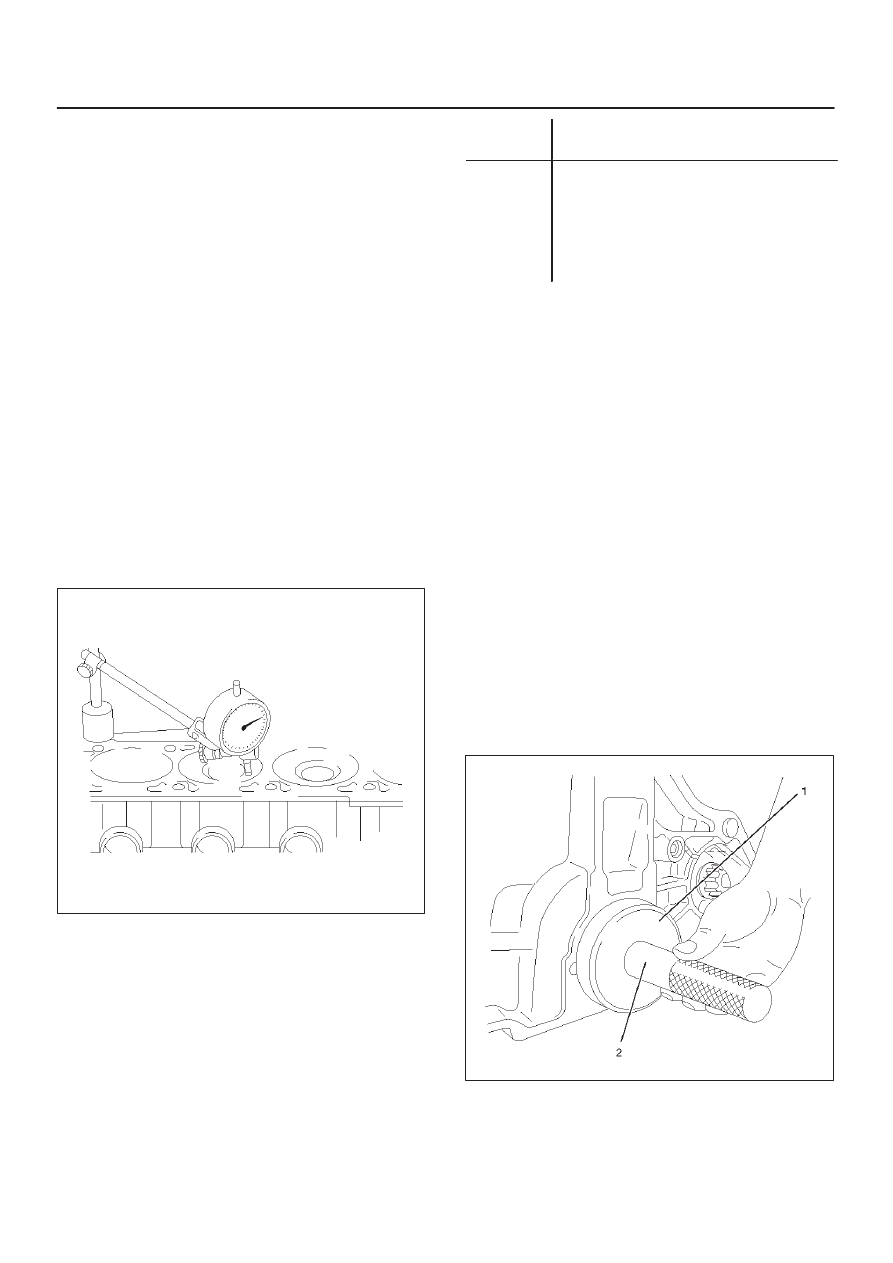

3. Install rear oil seal.

D

Coat lip of seal rings thinly with protective grease.

D

Install seal ring into cylinder block, use J–42616 (1)

and J–42613 (2).

015RW009

Refer to “Crankshaft” in this manual.