Content .. 1211 1212 1213 1214 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1213

6A–49

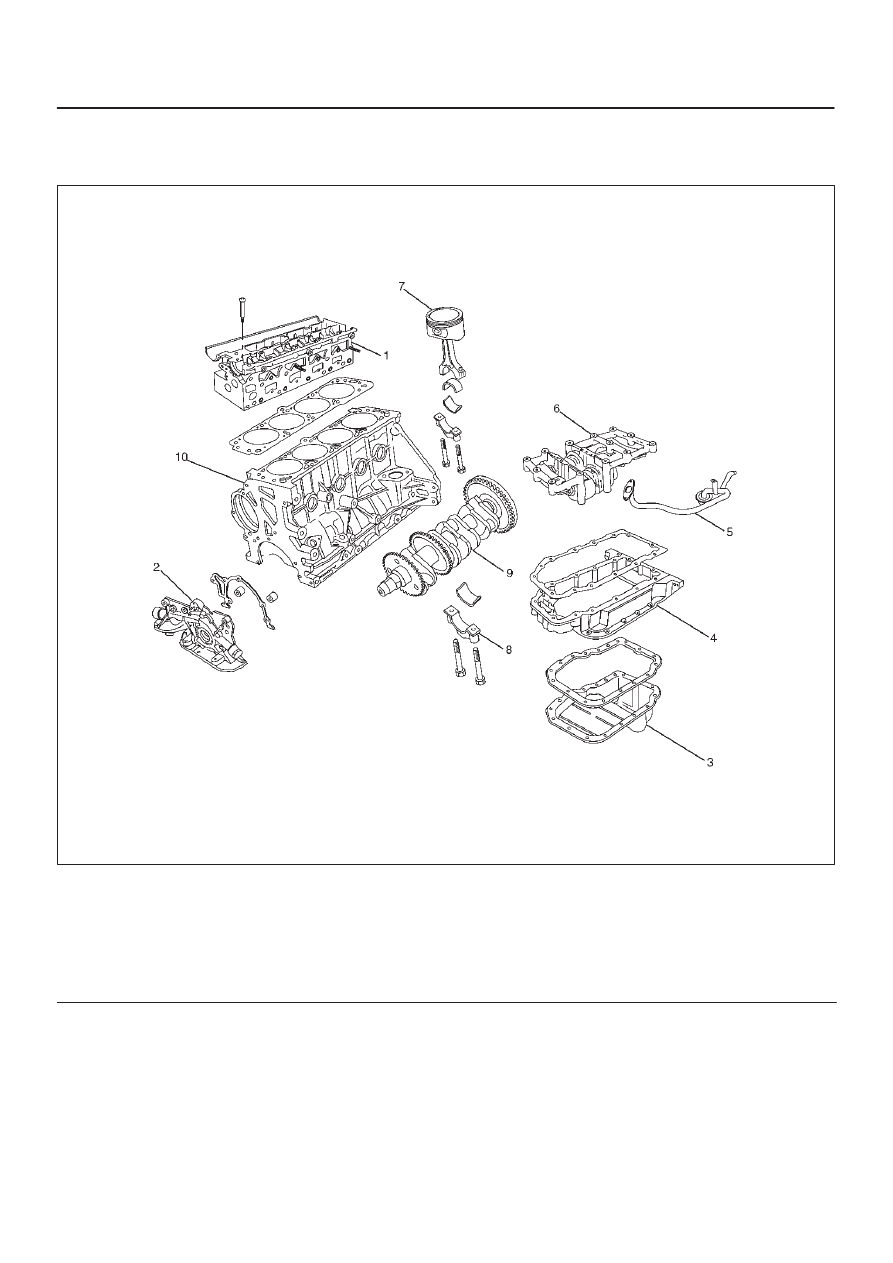

ENGINE MECHANICAL (Y22SE 2.2L)

Crankshaft

Crankshaft and Associated Parts

015R100024

Legend

(1) Cylinder Head Assembly

(2) Oil Pump Assembly

(3) Pan

(4) Pan Support

(5) Oil Strainer

(6) Balance Unit Assembly

(7) Piston and Connecting Rod Assembly

(8) Main Bearing Cap

(9) Crankshaft

(10) Cylinder Block Assembly

Disassembly

1. Remove cylinder head assembly (1). Refer to

“Cylinder head” in this manual.

2. Remove oil pan (3).

CAUTION: Take care not to damage or deform the

sealing flange surface of crankcase.

3. Remove oil pan support (4).

4. Remove oil strainer (5).

5. Remove oil pump assembly (2).

6. Balance unit assembly (6).

7. Remove piston and connecting rod assembly (7).

Refer to “Piston, Piston Ring and Connecting Rod” in

this manual.

8. Remove flywheel.

9. Remove rear oil seal and oil baffle plate.