Content .. 1185 1186 1187 1188 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1187

POWER-ASSISTED BRAKE SYSTEM

5C–15

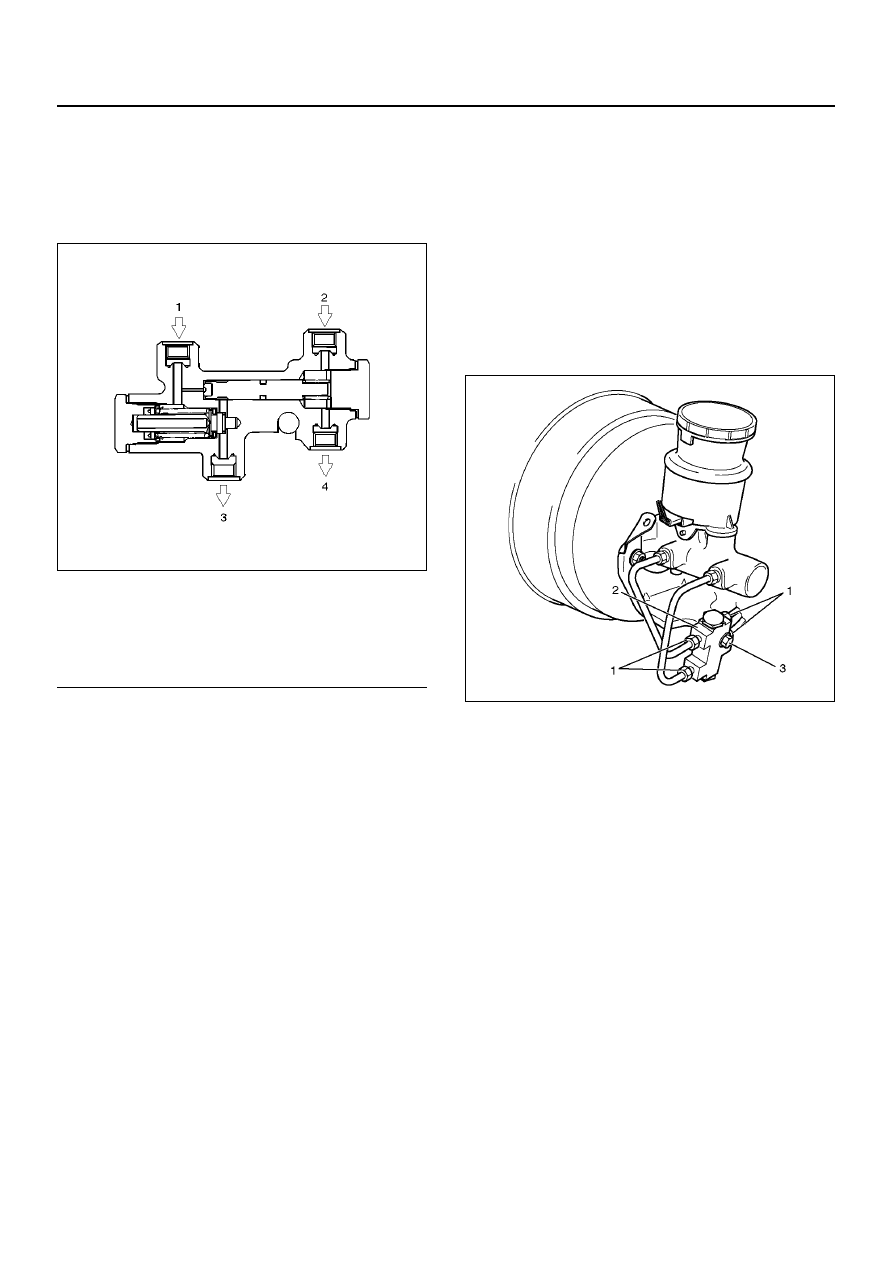

P & B (Proportioning and Bypass) Valve

P & B (Proportioning and Bypass)

Valve Sectional View

350RW014

EndOFCallout

The P&B valve contains two sections, each serving a

different function.

The proportioning section of the P&B valve proportions

outlet pressure to the rear brakes after a predetermined

rear input pressure has been reached. This is done to

prevent rear wheel lock up on the vehicles with light rear

wheel loads. The valve has a by–pass feature which

assures full system pressure to the rear brakes in the

event of front brake system malfunction. Also full front

pressure is retained in the event of rear brake

malfunction.

The P&B valve is not repairable and must be replaced

as complete assembly.

Removal

1. The P&B valve is not repairable and must be

replaced as a complete assembly. Care must be

taken to prevent brake fluid from contacting any

painted surface.

2. Remove hydraulic pipes (1) and plug the pipes (1)

to prevent the loss of fluid or the entrance of dirt.

3. Remove bolt (3).

4. Remove P&B valve (2).

350R200003

Installation

1. Install P&B valve (2).

2. Install bolt (3) and tighten the bolt to the specified

torque.

Torque: 22 N·m (16 lb ft)

3. Install hydraulic pipes (1) and tighten the bolt to the

specified torque.

Torque: 12 N·m (104 lb in)

4. After installing the brake pipes, bleed the brakes as

described in Bleeding Brake Hydraulic System in

this section.

Legend

(1) Master Cylinder (Secondary)

(2) Master Cylinder (Primary)

(3) Rear Brake

(4) Front Brake