Content .. 1179 1180 1181 1182 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1181

BRAKE CONTROL SYSTEM

5A–53

Chart B-24 Wheel Speed Input Abnormality (DTC 65 (Flash out) / C0238 (Serial

communications))

Sensor Signal Abnormality Criteria using TECH 2

1. While driving, the speed of one or two wheels is

25% or more higher or lower than that of the other

wheels.

2. The speed of one or two wheels is 10 km/h (6 mph)

or more higher or lower than that of the other

wheels.

3. During steady driving, wheel speed changes

abruptly.

*1 The vehicle must run on a level paved road.

NOTE: Even after repairing the faulty part the warning

light (W/L) does not go out if the vehicle is at a stop.

Turn the ignition switch to the ON position and drive the

vehicle at 12 km/h (8 mph) or higher to make sure that

the warning light goes out.

It is important to verify that the correct tires are installed

on vehicle.

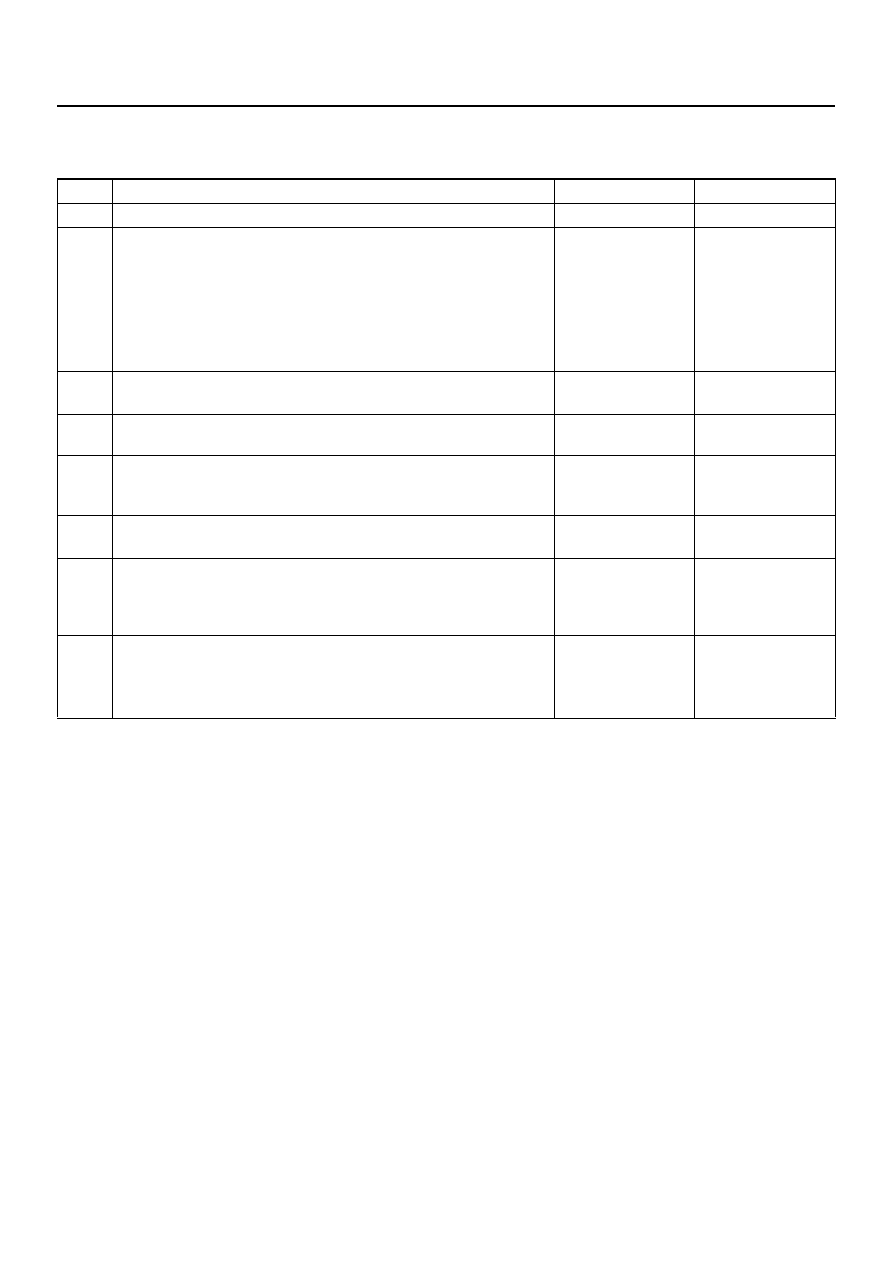

Step

Action

Yes

No

1

Using TECH 2?

Go to Step 2

Go to Step 3

2

1. Connect TECH 2.

2. Select Snap shot manual trigger.

3. With wheel speed data displayed, run the vehicle when

speed has arrived at 30 km/h (18 mph).

4. Check speed data on each wheel (refer to the criterion given

below). * 1

Is the abnormal sensor condition found?

Replace.

Go to Step 8

Go to Step 3

All the sensors

should follow

the following

flowchart

(without using

TECH 2).

3

Is there play in sensor/sensor ring?

Repair.

Go to Step 8

Go to Step 4

4

Is there powdered iron sticking to sensor/sensor ring?

Repair.

Go to Step 8

Go to Step 5

5

Is there a broken tooth or indentation in sensor ring?

Replace sensor

ring.

Go to Step 8

Go to Step 6

6

Is there play in wheel bearing?

Adjust or repair.

Go to Step 8

Go to Step 7

7

Is the check wiring between sensor and coil integrated module

normal?

Replace EHCU.

Go to Step 8

Repair, and

perform system

self-check.

Go to Step 8

8

1. Reconnect all components, ensure all components are

properly mounted.

2. Clear diagnostic trouble code.

Was this step finished?

Repeat Basic

diagnostic flow

chart"

Go to Step 8