Content .. 1168 1169 1170 1171 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1170

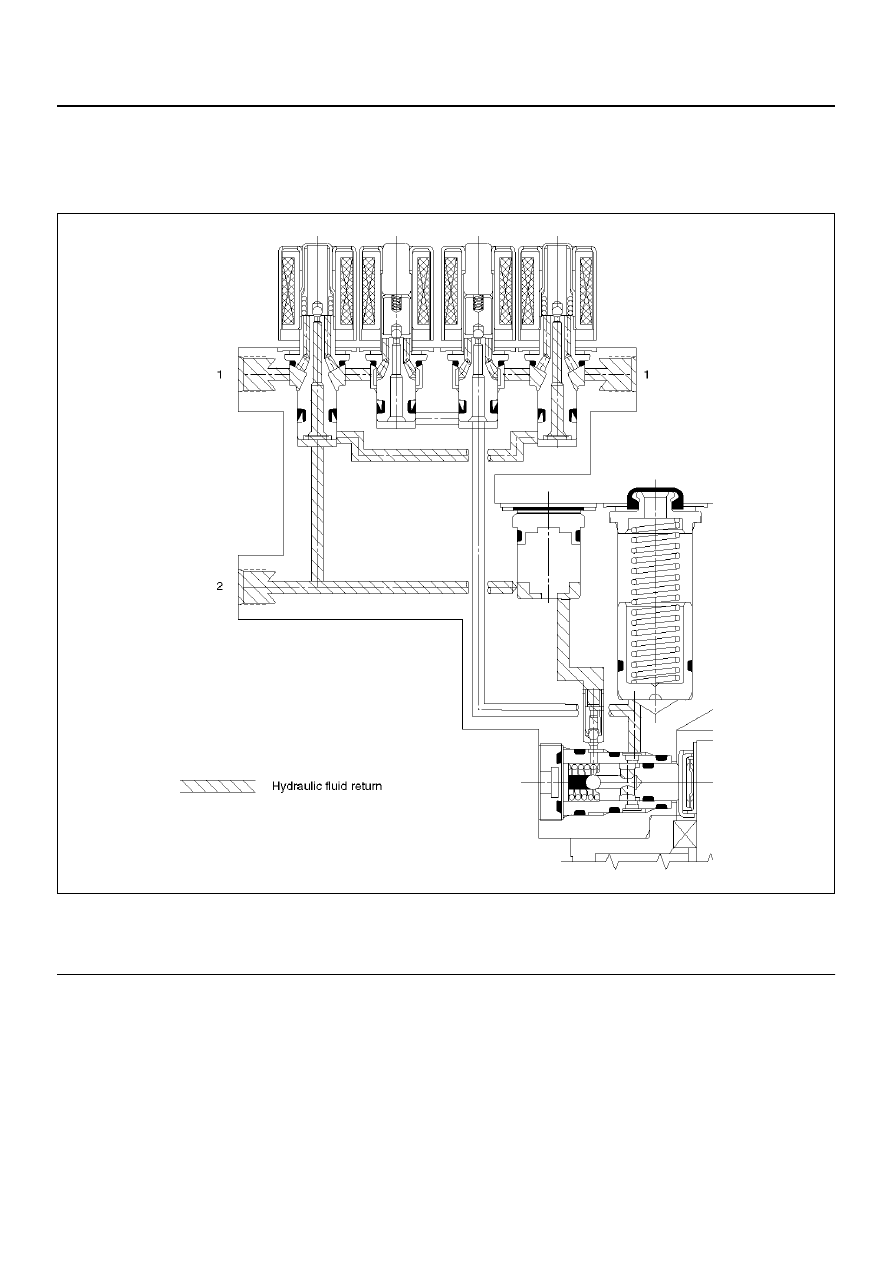

BRAKE CONTROL SYSTEM

5A–9

Brake Release

At the end of the anti-lock stop, when the brake pedal is

released, the pump will remain running for a short time

to help drain any fluid from the accumulators. As this

fluid returns into the system, the spring forces the piston

back to its original position.

The isolation valve opens and fluid may return to the

master cylinder. Conventional braking is then resumed.

C05RW013

EndOFCallout

Legend

(1) Brake

(2) Master Cylinder