Content .. 1137 1138 1139 1140 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1139

4A2–24

DIFFERENTIAL (REAR)

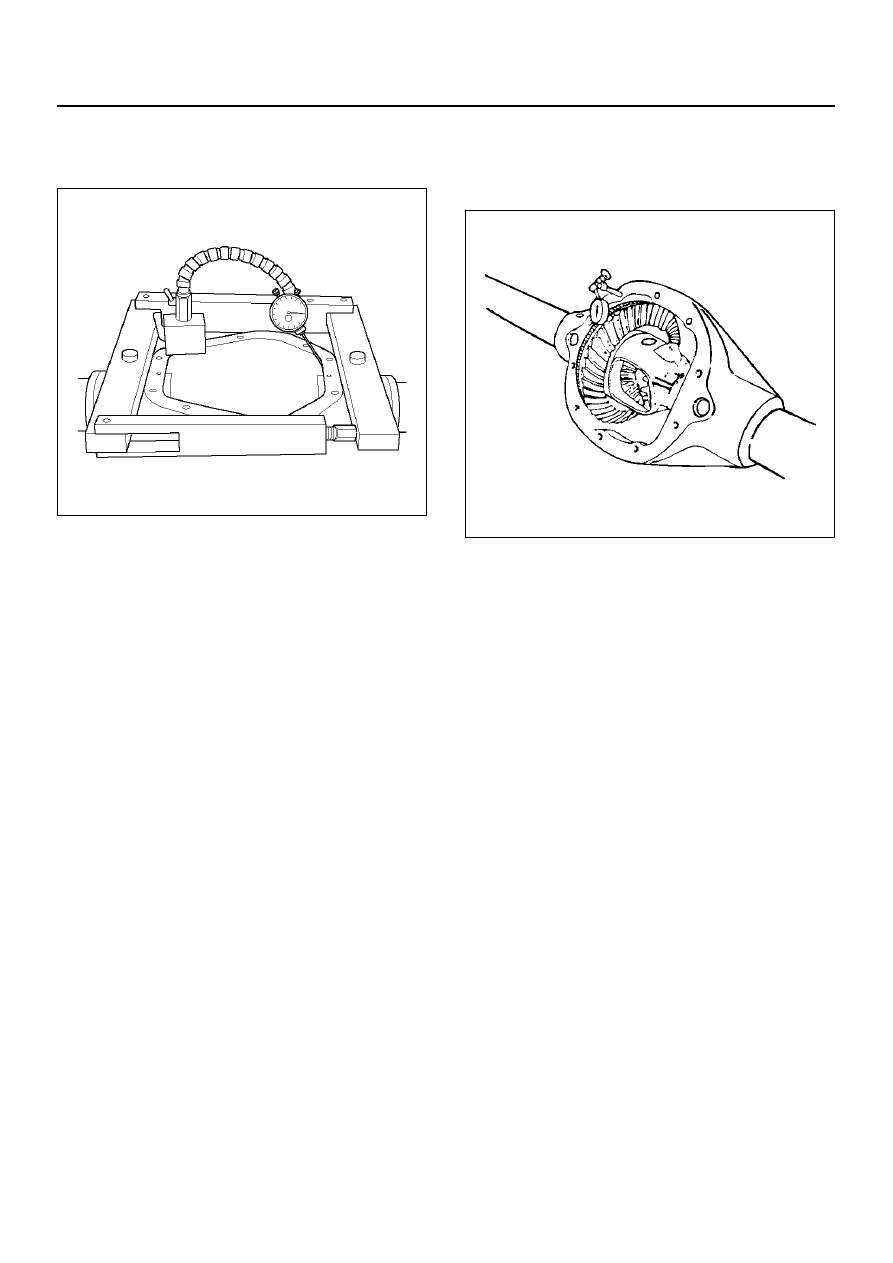

11. Assembly the spreader J–24385–B and indicator to

the carrier as shown in figure. Spread the carrier

0.5mm (0.02 in) for differential installation.

420RW004

CAUTION: Do not spread the carrier over 0.5 mm

(0.02 in).

12. Remove the indicator.

Backlash Adjustment

1. Install the differential case assembly and bearing

caps.

2. Rotate the case several times to seat the bearings.

3. Remove the spreader.

4. Install the side bearing cap bolts.

Tighten side bearing cap bolts

Torque: 108 N·m (80 lb ft)

5. Install a dial indicator to the case using a magnetic

base.

6. Place the indicator stem at the heel end of a tooth.

• Set the dial indicator so that the stem is in line

with the gear rotation and perpendicular to the

tooth angle.

425RS087

7. Check and record the backlash at three points

around the ring gear.

• The pinion must be held stationary when

checking backlash.

• The backlash should be the same at each point

within 0.07mm (0.003in). If the backlash varies

more than 0.07 mm (0.003in), check for burrs, a

distorted case flange, or uneven bolting

conditions.

8. Backlash at the minimum lash point measured

should be between 0.13 and 0.20mm (0.005 and

0.008 in) for all new gear sets.

9. If the backlash is not within specifications, move the

ring gear in or out from the pinion by increasing the

thickness of one shims, and decreasing the

thickness of the other shim by the same amount.

This will maintain the correct rear axls side bearing

preload.

• Moving 0.05 mm (0.002 in) worth of shim from one

side of the differential to the other will change the

backlash adjustment by 0.03mm (0.001 in).

10. After obtaining correct tooth contact described in

later, install ABS speed sensor.

11. Install the cover with sealant.

Torque: 40 N·m (30 lb ft)

12. Fill the axle lubricant.