Content .. 1122 1123 1124 1125 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1124

3F–26

INTELLIGENT SUSPENSION

DTC7 Engine Speed Signal Open Circuit or Short

Circuit Description

PCM (Powertrain Control Module) converts signals from

the crankshaft position sensor into the engine speed

signals (pulse) and sends these to the control unit and

tachometer.

Diagnostic Aids

• Inspect the wiring for poor electrical connections at

the control unit connector. Look for possible bent,

backed out, deformed, or damaged terminals. Check

for weak terminal tension as well.

Also check for a chafed wire that could short to bare

metal or other wiring. Inspect for a broken wire inside

the insulation.

• When diagnosing for a possible intermittent short or

open condition, move the wiring harness while

observing test equipment for a change.

• Check harness routing for a potential short to ground

in circuit BLK/RED.

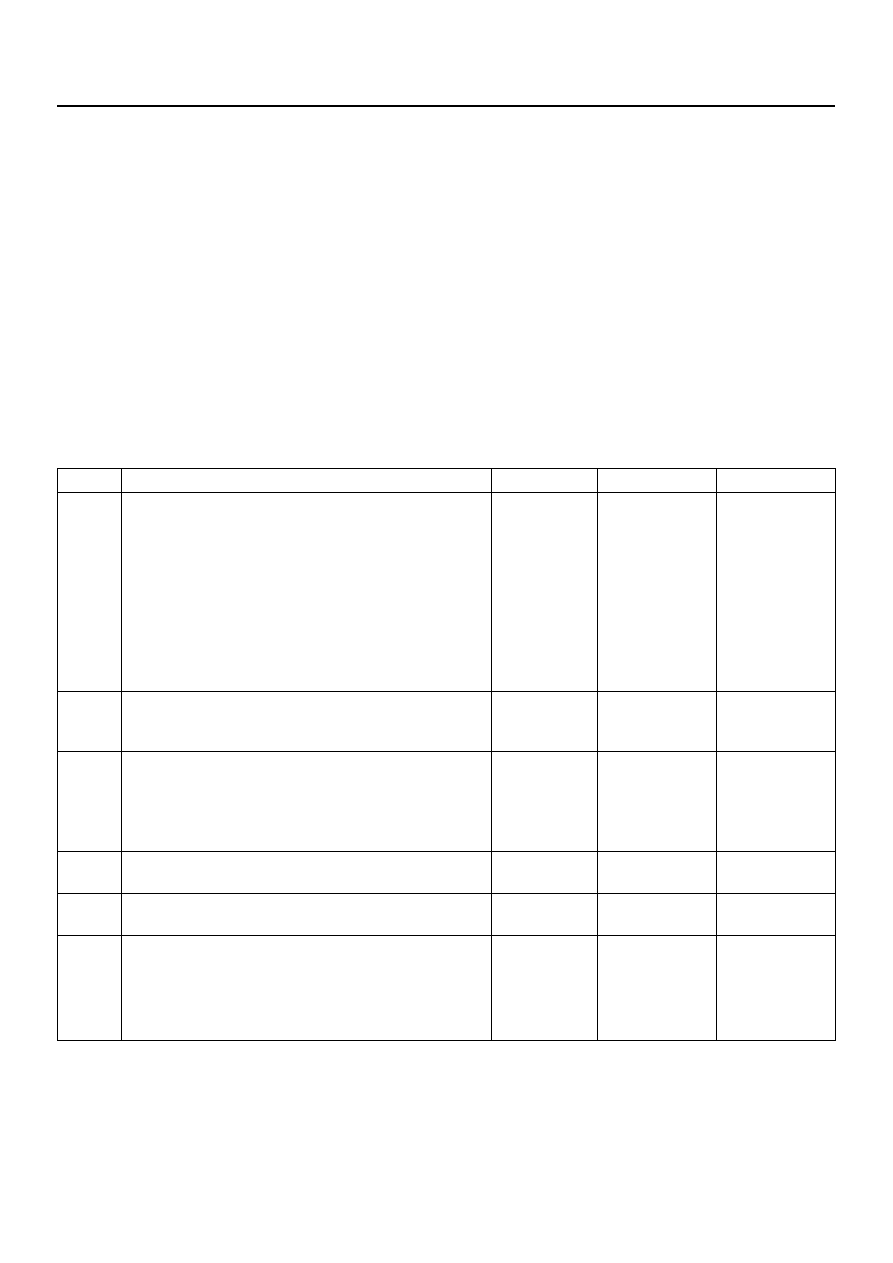

DTC7 Engine Speed Signal Open Circuit or Short

Step

Action

Value(s)

Yes

No

1

NOTE: Confirm that DTC P0336 or P0337 does not

exist.

If either exists, warning lamps, “CHECK ENGINE" and

“CHECK TRANS" are turned on. Repair the engine,

referring to Section 6E “Driveability and Emission".

1. Turn on the starter switch.

2. Start the engine.

3. Open the throttle and rev up engine speed.

Does the tachometer operate according to engine

speed?

—

Go to Step 3

Go to Step 2

2

Repair the tachometer, referring to Section 8D Wiring

System in Body and Accessories.

—

Go to Step 6

—

3

1. Turn off the starter switch.

2. Check continuity between the control unit

connector C–52 terminal 59 and PCM connector

E–21 terminal F7.

Is there continuity ?

—

Go to Step 4

Go to Step 5

4

Replace the control unit.

—

Go to Step 6

—

5

Repair the circuit.

—

Go to Step 6

—

6

1. Reconnect all components, ensure all

components are properly mounted.

2. Clear the DTC.

3. Conduct a test drive.

Has the last test failed or does the current DTC exist?

—

Begin

diagnosis

again

Go to Step 1

Repair verified