Content .. 1092 1093 1094 1095 ..

Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 1094

POWER-ASSISTED STEERING SYSTEM

2A–13

Caster (1) is the vertical tilting of the wheel axis either

forward or backward (when viewed from the side of the

vehicle). A backward tilt is positive (+) and a forward tilt

is negative (-). On the short and long arm type

suspension you cannot see a caster angle without a

special instrument, but if you look straight down from

the top of the upper control arm to the ground, the ball

joints do not line up (fore and aft) when a caster angle

other than 0 degree is present. With a positive angle,

the lower ball joint would be slightly ahead (toward the

front of the vehicle) of the upper ball joint center line.

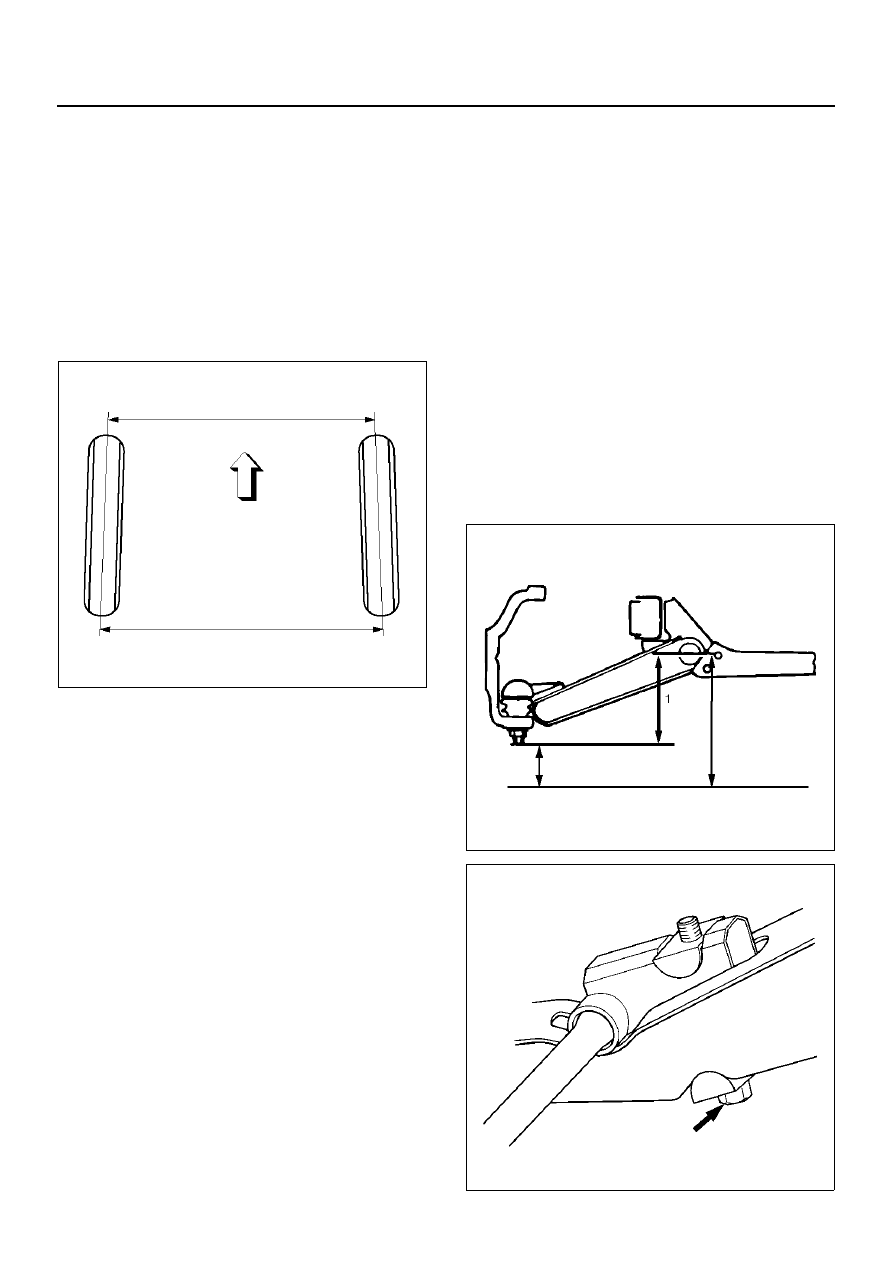

Toe-in:

This illustration shows view from the top of the vehicle.

480RS003

Toe-in is the measured amount the front wheels are

turned in. The actual amount of toe-in is normally a

fraction of a degree. Toe-in is measured from the center

of the tire treads or from the inside of the tires. The

purpose of toe-in is to insure parallel rolling of the front

wheels and to offset any small deflections of the wheel

support system which occurs when the vehicle is rolling

forward. Incorrect toe-in results in excessive toe-in and

unstable steering. Toe-in is the last alignment to be set

in the front end alignment procedure.

Inspection

Before making any adjustments affecting caster,

camber or toe-in, the following front end inspection

should be made.

1. Inspect the tires for proper inflation pressure. Refer

to Main Data and Specifications in Wheel and Tire

System section.

2. Make sure that the vehicle is unladen condition

(With no passenger or loading).

3. Make sure that the spare tire is installed at the

normal position.

4. Inspect the front wheel bearings for proper

adjustment. Refer to Front Hub and Disc Overhaul

in Suspension section.

5. Inspect the ball joints and tie rod ends. If excessive

looseness is noted, correct before adjusting. Refer

to Steering Linkage in this section.

6. Inspect the wheel and tires for run-out. Refer to

Wheel Replacement in Wheel and Tire System

section.

7. Inspect the trim height. If not within specifications,

the correction must be made before adjusting

caster.

8. Inspect the steering unit for looseness at the frame.

9. Inspect shock absorbers for leaks or any noticeable

noise. Refer to Shock Absorber in Suspension

section.

10. Inspect the control arms or stabilizer bar attachment

for looseness. Refer to Suspension section .

11. Inspect the front end alignment using alignment

equipment. Follow the manufacturer's instructions.

12. Park the vehicle on a level surface.

Trim Height Adjustment

Adjust the trim height (1) by means of the adjusting bolt

on the height control arms.

CAUTION: When adjusting front end alignment, be

sure to begin with trim height first, as it may change

other adjusted alignments.

450RS003

410RS001