Isuzu Amigo / Axiom / Trooper / Rodeo / VehiCross. Manual - part 19

HEATING, VENTILATION AND AIR CONDITIONING (HVAC) 1A–47

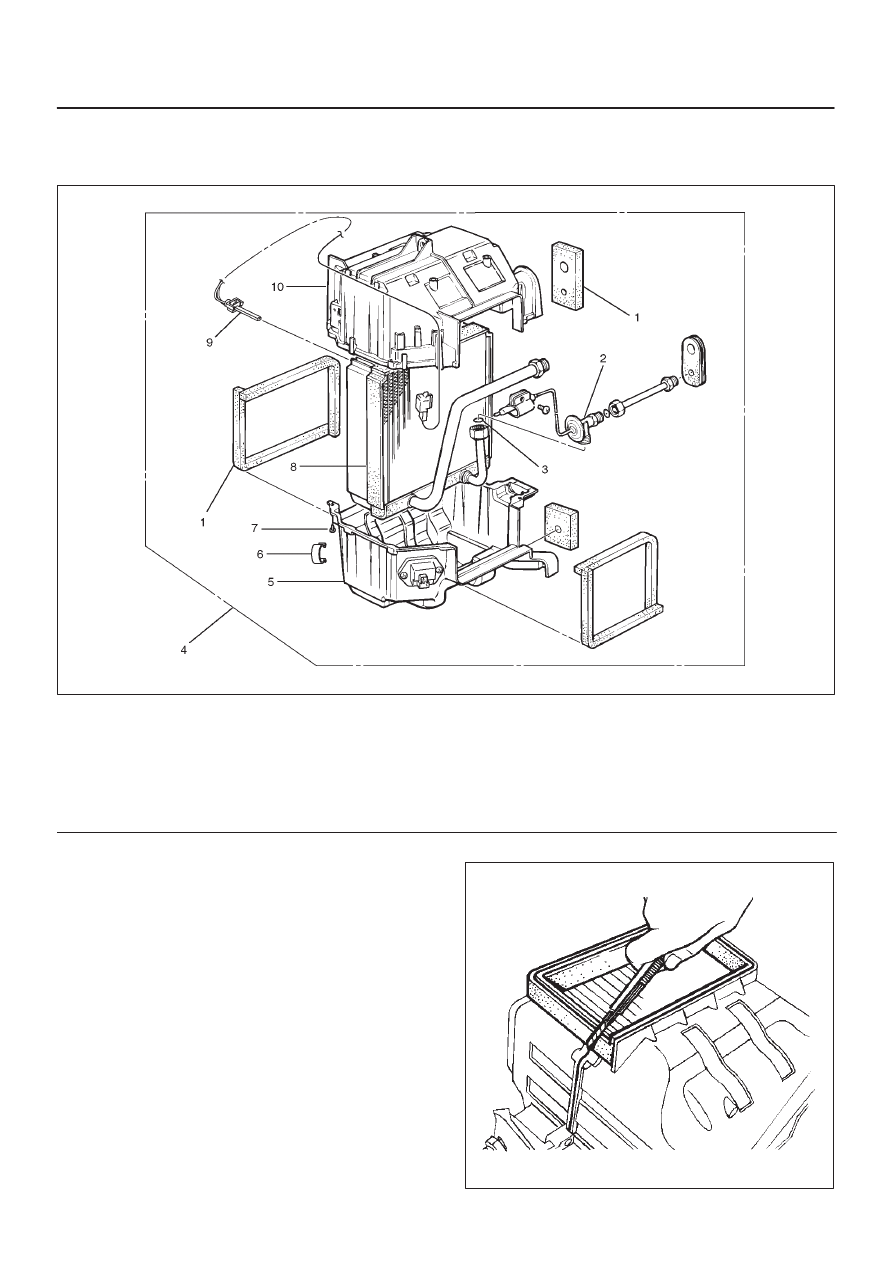

Duct Sensor, Evaporator Core and/or Expansion Valve

Disassembled View

874R200012

Legend

(1) Lining

(2) Expansion Valve

(3) O-ring

(4) Evaporator Assembly

(5) Lower Case

(6) Clip

(7) Attaching Screw

(8) Evaporator Core

(9) Duct Sensor

(10) Upper Case

Removal

1. Disconnect the battery ground cable.

2. Discharge and recover refrigerant.

D

Refer to

Refrigerant Recovery in this section.

3. Remove evaporator assembly.

D

Refer to

Evaporator Assembly in this section.

4. Remove the duct sensor fixing clip.

Pull the sensor from the evaporator assembly.

5. Remove clip.

6. Remove attaching screw.

7. Remove upper case.

8. Remove lower case.

D

Slit the case parting face with a knife since the lining

is separated when removing the evaporator.

874RS006