Isuzu Trooper (1998-2002 year). Manual - part 450

6E–170

6VE1 3.5 ENGINE DRIVEABILITY AND EMISSIONS

D

Poor connection at PCM – Inspect harness connectors

for backed-out terminals, improper mating, broken

locks, improperly formed or damaged terminals, and

poor terminal-to-wire connection.

D

Damaged harness – Inspect the wiring harness for

damage. If the harness appears to be OK, observe the

ECT display on the Tech 2 while moving connectors

and wiring harnesses related to the sensor. A change

in the display will indicate the location of the fault.

Reviewing the Failure Records vehicle mileage since the

diagnostic test last failed may help determine how often

the condition that caused the DTC to be set occurs. This

may assist in diagnosing the condition.

Test Description

Number(s) below refer to the step number(s) on the

Diagnostic Chart.

2. The HO2S should be allowed to cool before

performing this test. If the HO2S heater is

functioning, the signal voltage will gradually increase

or decrease as the sensor element warms. If the

heater is not functioning, the HO2S signal will

remain near the 450 mV bias voltage.

4. Ensures that the ignition feed circuit to the HO2S is

not open or shorted. The test light should be

connected to a good chassis ground, in case the

HO2S low or HO2S heater ground circuit is faulty.

5. Checks the HO2S heater ground circuit.

6. Checks or an open or shorted HO2S heater element.

10.An open HO2S signal or low circuit can cause the

HO2S heater to appear faulty. Check these circuits

before replacing the sensor.

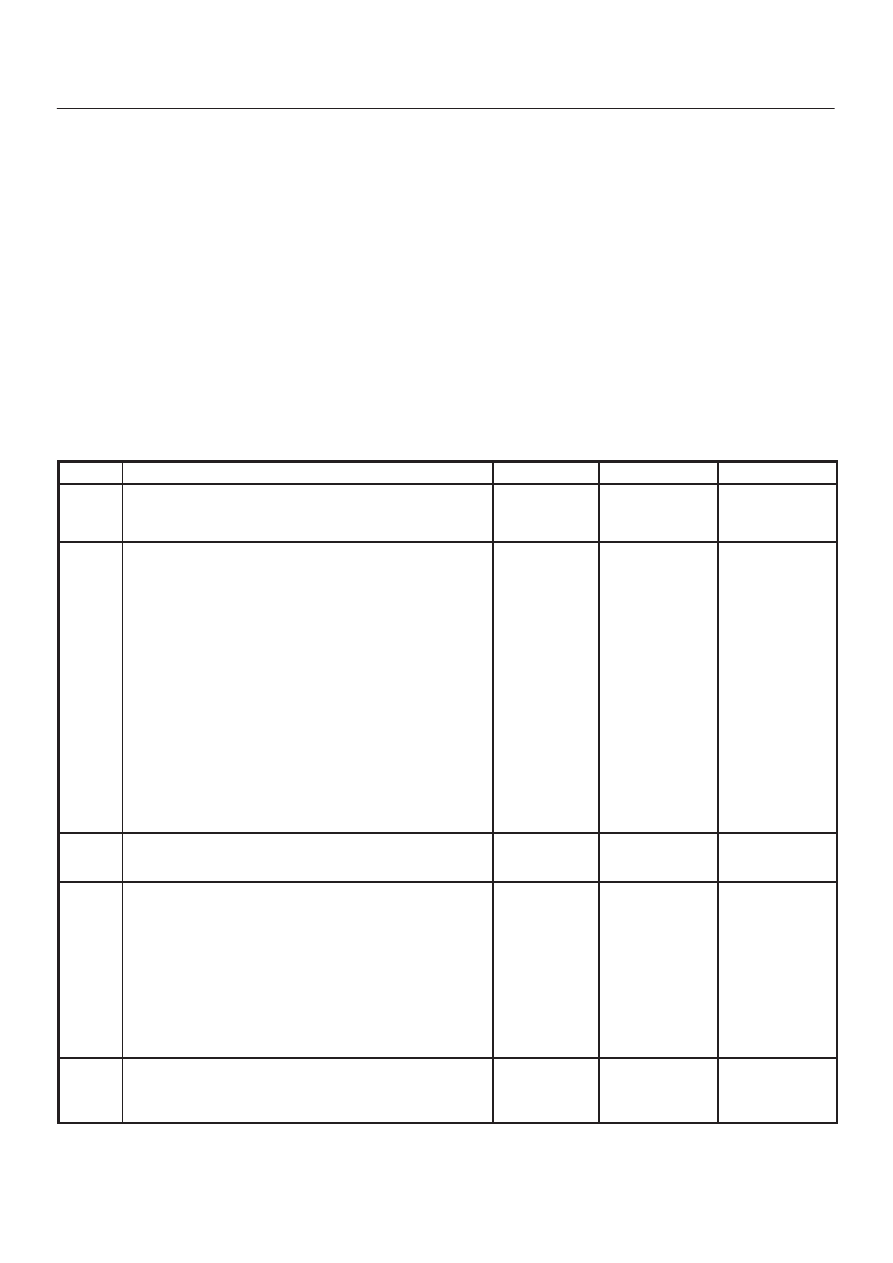

DTC P0135 – HO2S Heater Circuit Bank 1 Sensor 1

Step

Action

Value(s)

Yes

No

1

Was the “On-Board Diagnostic (OBD) System Check”

performed?

—

Go to

Step 2

Go to

OBD

System

Check

2

NOTE: If the engine has just been operating ,allow the

engine to cool for at least 15 minutes before

proceeding.

1. Remove the fuel pump relay.

2. Connect a fused jumper at the fuel pump relay

socket, between the battery positive at the relay and

the relay wire that leads to the fuel pump and HO2S

fuses.

3. Ignition “OFF”.

4. Install a Tech 2.

5. Ignition “ON”, engine “OFF”.

6. Monitor the Bank 1 HO2S 1 voltage for several

minutes.

Did the HO2S voltage go from bias voltage to above or

below the specified values?

Above

650 mV or

below

250 mV

Check the

Procedure

Refer to

Diagnostic

Aids

Go to

Step 3

3

Inspect the fuse for the Bank 1 HO2S 1 ignition feed.

Is the fuse open?

—

Go to

Step 15

Go to

Step 4

4

1. Ignition “OFF”.

2. Raise the vehicle.

3. Disconnect the Bank 1 HO2S 1 electrical connector.

4. Using a test light connected to a good ground (do

not use Bank 1 HO2S 1 heater ground or Bank 1

HO2S 1 low), probe the ignition feed circuit at the

Bank 1 HO2S 1 electrical connector (PCM harness

side).

Does the test light illuminate?

—

Go to

Step 5

Go to

Step 7

5

Connect the test light between the Bank 1 HO2S 1

ignition feed and the Bank 1 HO2S 1 heater ground.

Does the test light illuminate?

—

Go to

Step 6

Go to

Step 8