Isuzu N-Series. Manual - part 566

GENERAL ENGINE MECHANICAL 6A-21

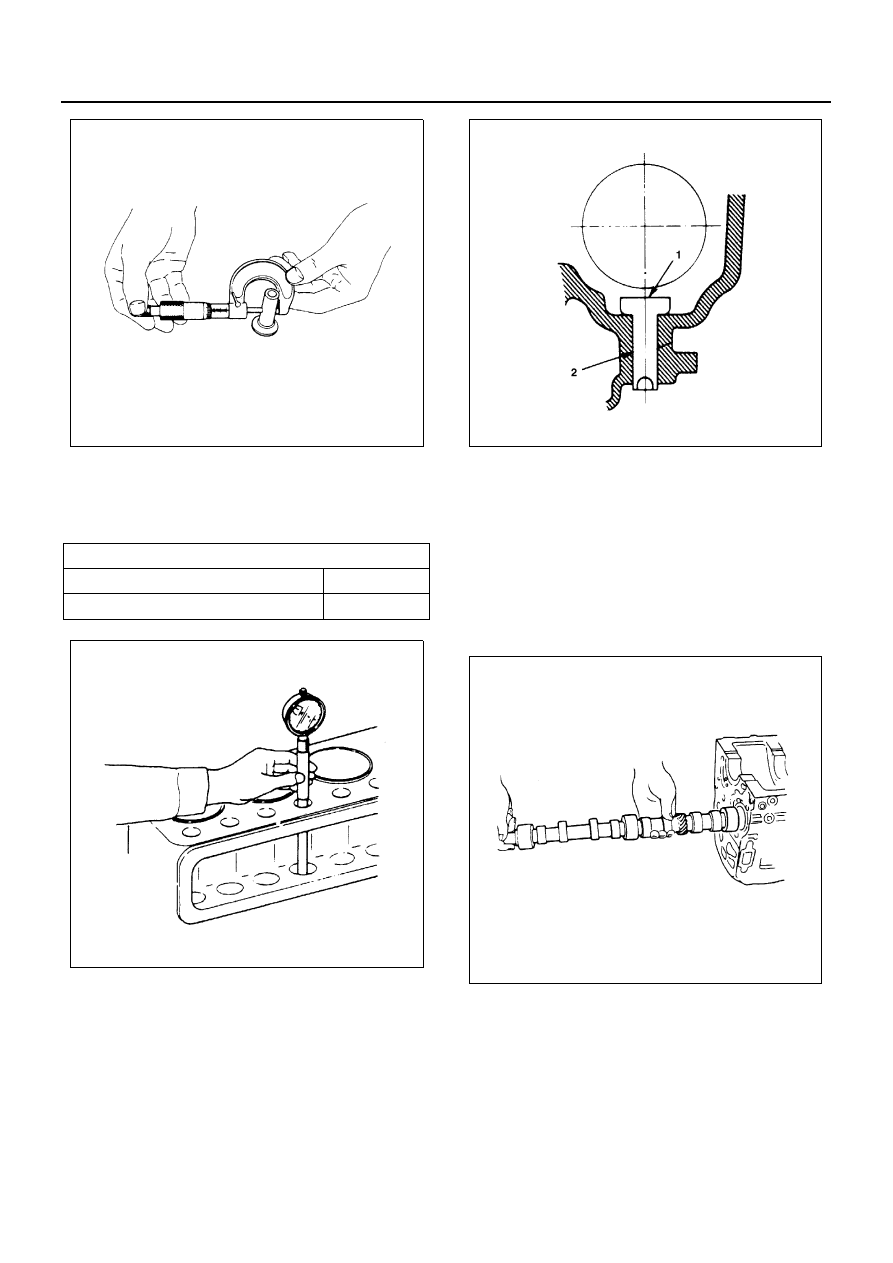

2. Measure the inside diameter tappet on the cylinder

block and calculate the clearance.

If the clearance exceeds the limit, replace tappet

or/and cylinder block.

Reassembly

1. Tappet

1) Apply a coat of engine oil to the tappet (1) and

the cylinder body tappet insert holes (2).

2) Locate the position mark applies at disassem-

bly (if the tappet is to be reused).

Notice:

The tappet must be installed before the camshaft.

2. Camshaft

1) Apply a coat of engine oil to the camshaft and

the camshaft bearings.

2) Install the camshaft to the cylinder body.

Take care not damage the camshaft bearings.

3. Camshaft Timing Pulley Center (Belt Drive Model)

• Apply engine oil to the oil seal lip portion of the

oil seal retainer.

• Apply the recommended liquid gasket or its

equivalent to the retainer.

• Install the oil seal retainer to the cylinder body.

• Tighten the retainer bolts to the specified

torque.

Tappet and Cylinder Body Clearance

mm (in)

Standard

Limit

0.03 (0.001)

0.10 (0.004)

N6A3103E

N6A3104E

N6A3105E

N6A3106E