Isuzu engine 4j series. Manual - part 96

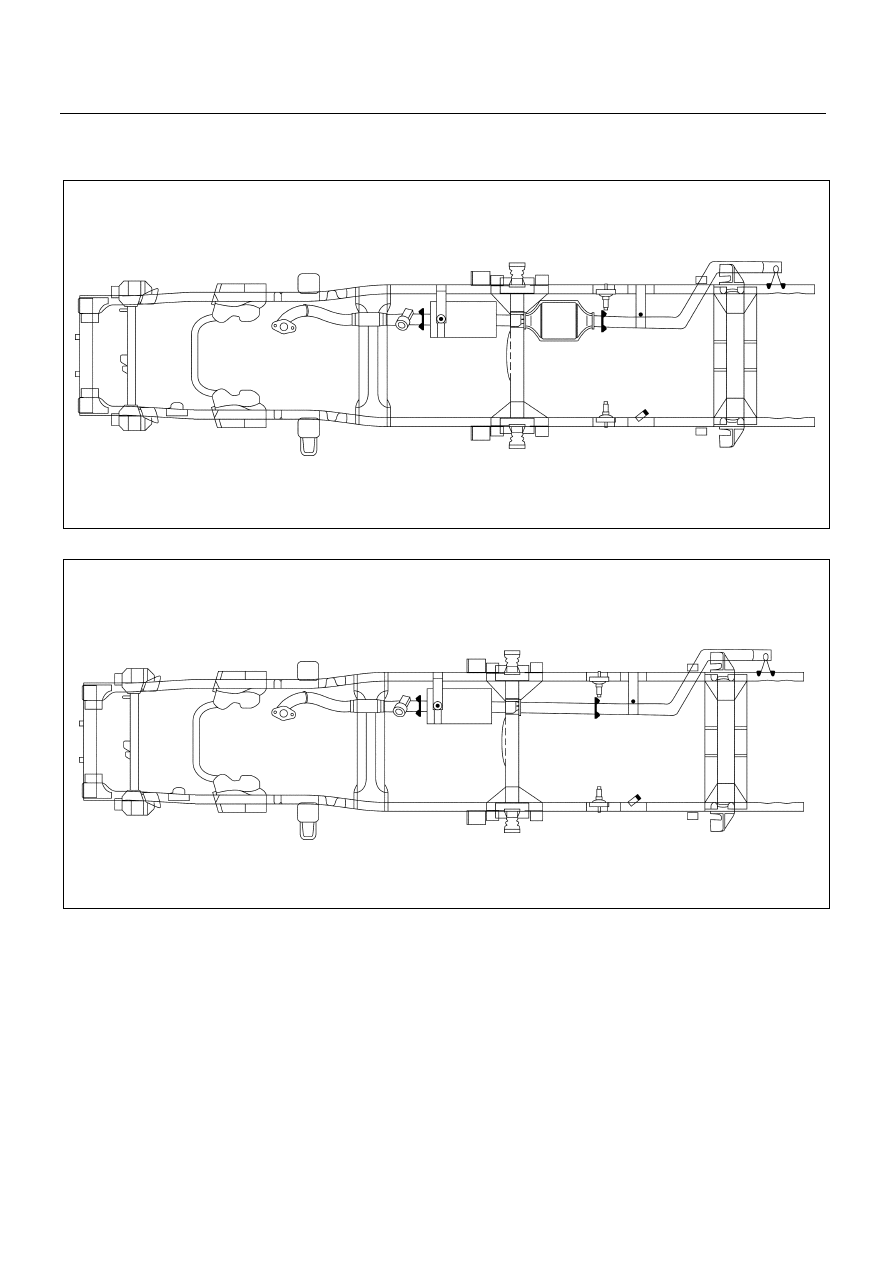

6F – 2 ENGINE EXHAUST

GENERAL DESCRIPTION

When inspecting or replacing exhaust system components,

make sure there is adequate clearance from all points on the

underbody to prevent overheating of the floor pan and possible

damage to the passenger compartment insulation and trim

materials.

Check complete exhaust system and nearby body areas and

rear compartment lid for broken, damaged, missing or

mispositioned parts, open seams, holes, loose connections or

other deterioration which could permit exhaust fumes to seep

into the rear compartment or passenger compartment. Dust or

water in the rear compartment may be an indication of a

problem in one of these areas. Any faulty areas should be

corrected immediately.

General Export

501LX002.tif

501LX003.tif

Model ’91/542B (Euro 2)