Isuzu engine 4j series. Manual - part 85

6D2 – 10 STARTING SYSTEM

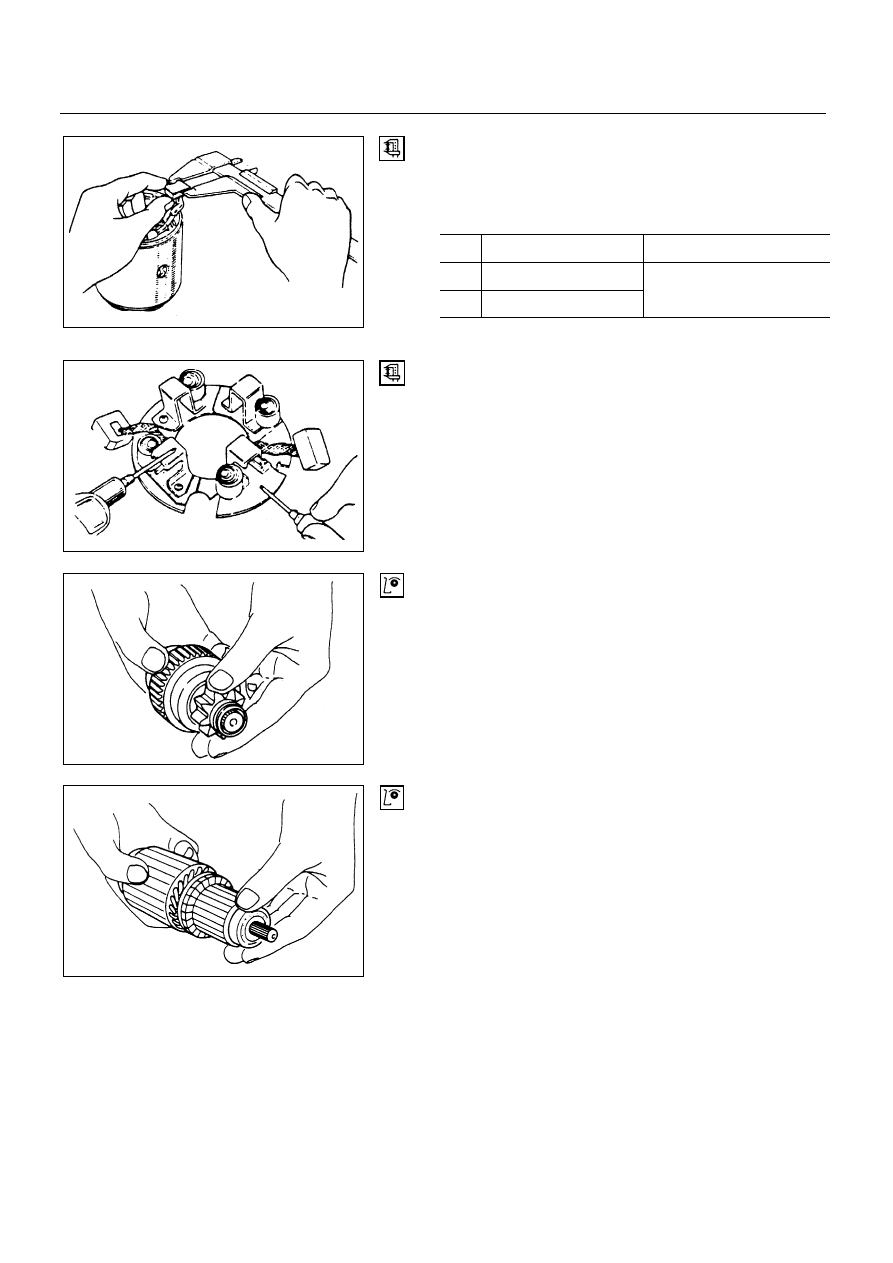

BRUSH AND BRUSH HOLDER

Measure the brush length and replace if it is worn beyond

the service limit.

Brush length

mm (in.)

kw

Standard

Limit

2.2

14.5 (0.57)

2.0

16 (0.63)

10 (0.39)

Brush holder insulation test

Using a circuit tester, check the brush holder insulation.

Touch one probe to the holder plate and the other to the

positive brush holder. There should be no continuity.

OVERRUNNING CLUTCH

Inspect the teeth of pinion for wear and damage.

Replace if it damaged.

Rotate the pinion in direction of rotation (clockwise).

It should rotate smoothly. But in opposite direction, it

should be locked.

BEARING

Check the bearings for wear and damage. If the bearings

are noisy during operation, they should be replaceds.

6D2-10-1.tif

6D2-10-2.tif

6D2-10-3.tif

6D2-10-4.tif