Isuzu engine 4j series. Manual - part 32

6A – 64

GENERAL ENGINE MECHANICAL

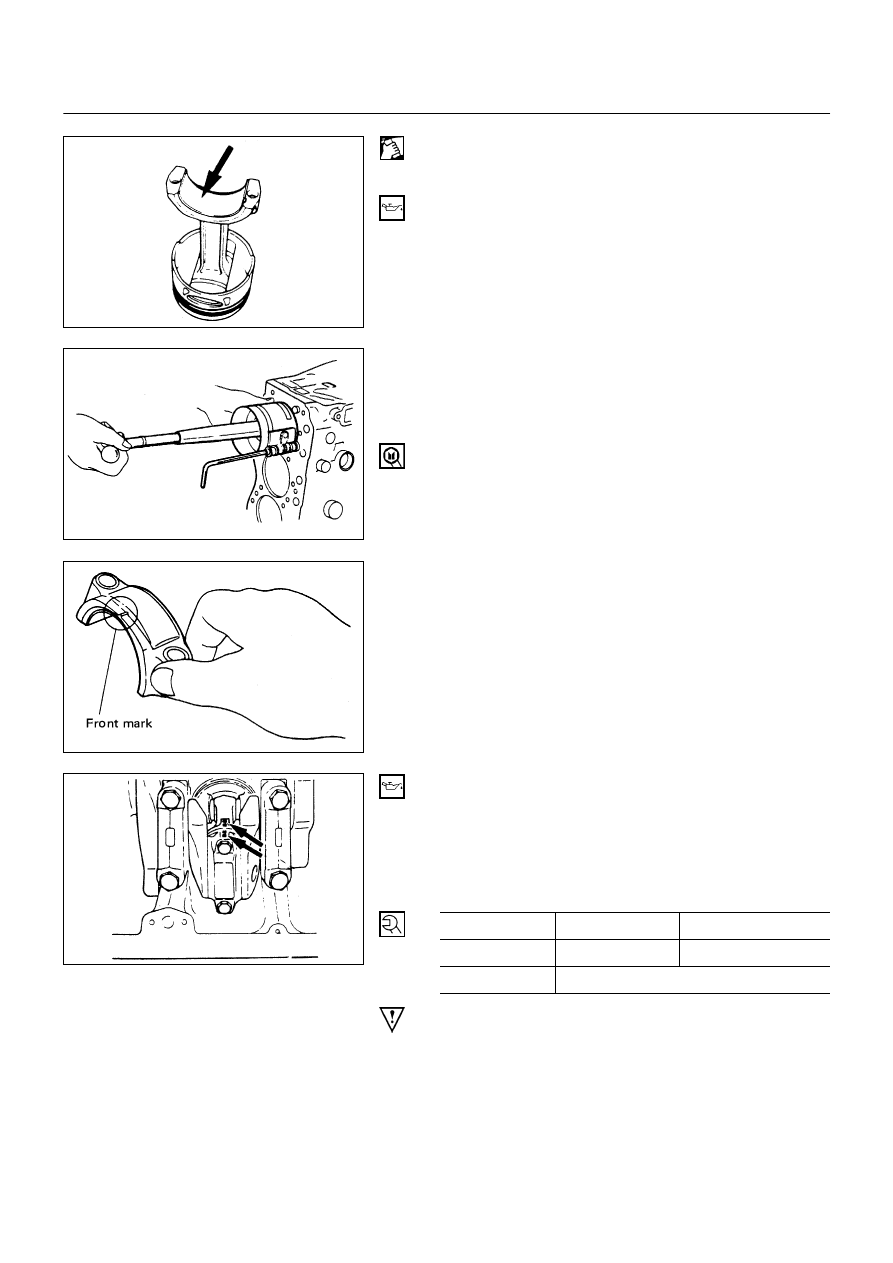

12) Carefully wipe any oil or other foreign material from

connect rod bearing back face and the connecting rod

bearing fitting surface.

13) Apply a coat of engine oil to the upper bearing

surfaces.

Apply a coat of engine oil to the cylinder wall.

14) Position the piston head from mark so that it is facing

the front of engine.

Use the piston ring compressor to compress the piston

rings.

Piston Ring Compressor: 5-8840-9018-0 (J-8037)

15) Use a hammer grip to push the piston in until the

connecting rod makes contact with the crankpin.

At the same time, rotate the crankshaft until the

crankpin is at BDC.

16) Position the bearing cap front mark so that it is facing

the front of the engine.

17) Install the connecting rod bearing caps.

Align the bearing cap cylinder number marks and the

connecting rod cylinder number marks.

18) Apply a coat of engine oil to the threads and setting

faces of each connecting rod cap bolt.

19) Tighten the connecting rod bearing cap bolts to the

specified torque in two steps using the Angular

Tightening Method.

Connecting Rod Bearing Cap Bolt

Torque

N∙m (kg∙m/lb∙ft)

1st Step

2nd Step

4JG2

29 (3.0/22)

45° - 75°

4JB1/4JB1TC

83 (8.5/61)

NOTE

Check to see that the crankshaft turns smoothly by

rotating it manually.

6A-64-1.tif

6A-64-3.tif

6A-64-2.tif

6A-64-4.tif