Isuzu KB P190. Manual - part 889

Engine Management – V6 – Service Operations

Page 6C1-3–32

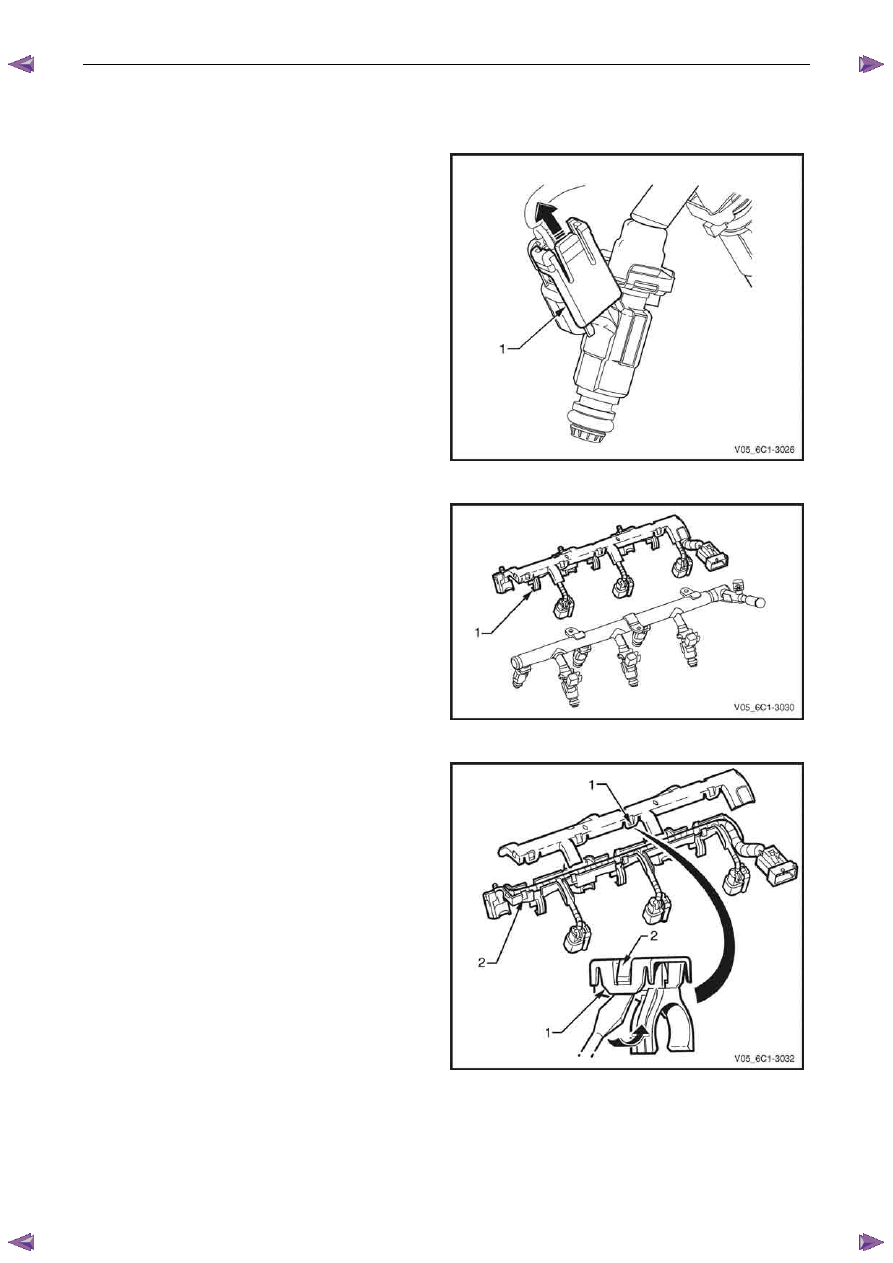

Fuel Injector Wiring Harness Assembly

Remove

1

For each fuel injector wiring harness connector, slide

the locking tab (1) upwards in the direction of the

arrow and disconnect the connector from the fuel

injector.

Figure 6C1-3 – 38

2

Unclip the fuel injector harness assembly (1), three

places, from the fuel rail.

Figure 6C1-3 – 39

3

Using a flat blade screwdriver, prise the fuel injector

harness upper tray retainer (1), eight places, from the

lower tray locking tang (2).

4

Remove the fuel injector harness from the lower tray.

Figure 6C1-3 – 40