Isuzu KB P190. Manual - part 871

Engine Management – V6 – Diagnostics

Page 6C1-2–206

•

The engine is running.

Conditions for Setting the DTC

DTC P2227

The ECM detects the BARO pressure changed greater than 5 kPa within 20 seconds or the BARO pressure changed

greater than 30 kPa since the last ignition cycle.

DTC P2228

The ECM detects the BARO sensor signal voltage is less than 0.20 V.

DTC P2229

The ECM detects the BARO sensor signal voltage is greater than 4.8 V for longer than 2.0 seconds.

Conditions for Clearing DTC

The BARO pressure sensor circuit DTCs are Type ‘B’ DTC. Refer to 1.4

Diagnostic Trouble Codes in this Section, for

action taken when a Type ‘B’ DTC sets and conditions for clearing Type ‘B’ DTCs.

Additional Information

•

Refer to 6C1-1 Engine Management – V6 – General Information for details of the BARO Sensor operation.

•

For an intermittent fault condition, refer to 5.2

Intermittent Fault Conditions in this Section.

•

Since fault condition in a wiring connector may trigger DTCs, always test the connectors related to this diagnostic

procedure for shorted terminals or poor wiring connection before replacing any component. Refer to 8A Electrical -

Body and Chassis for information on electrical fault diagnosis.

•

To assist diagnosis, refer to 3

Wiring Diagrams and Connector Charts in this Section, for the system wiring

diagram and connector charts.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

4

Test signal circuit of the BARO sensor. This circuit should display a voltage within the specified range.

5

Measures the integrity of the TP sensor low reference circuit. Removal of the ECM Fuse 29 enables the ECM to

power down completely prior to the test procedure.

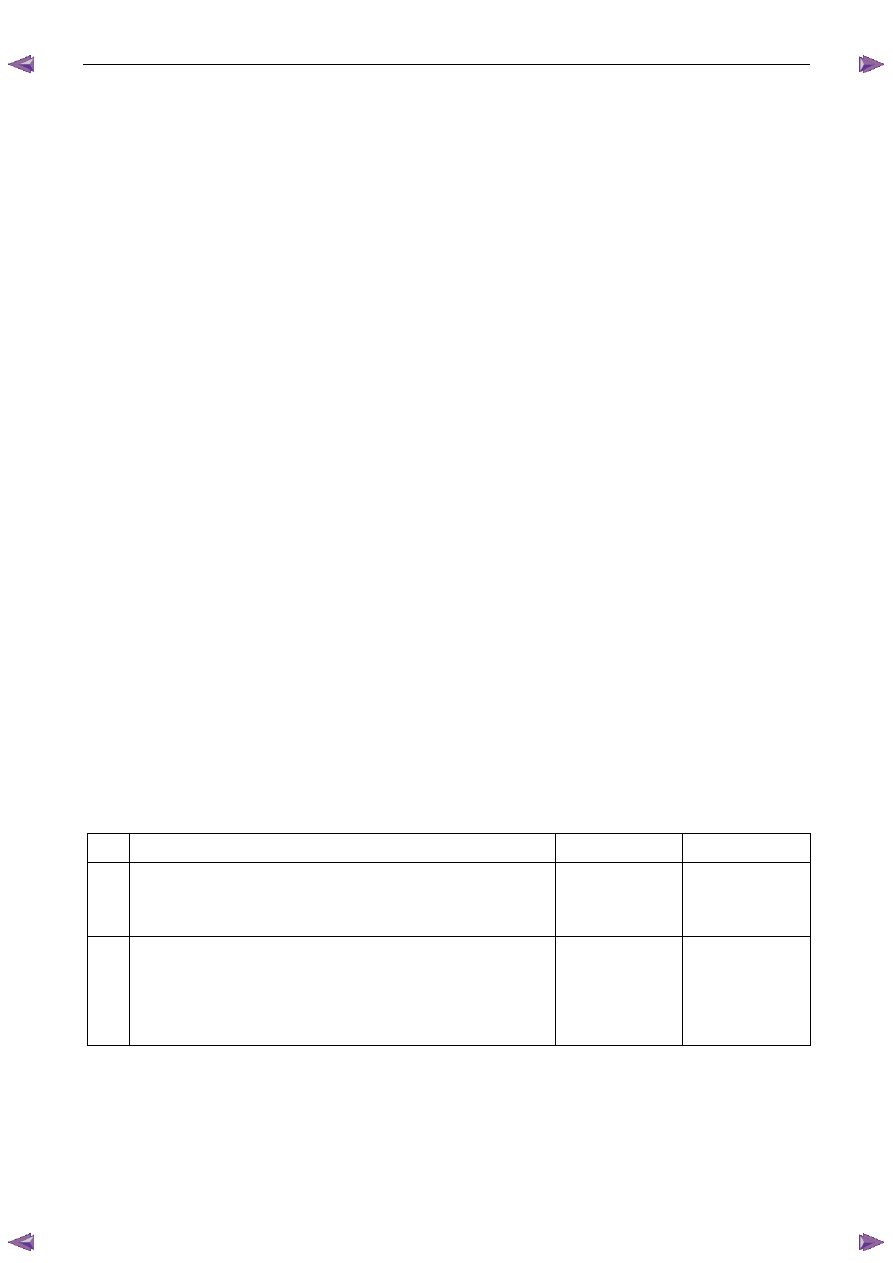

DTC P2227 P2228 or P2229 Diagnostic Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P2227, P2228 or P2229 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC