Isuzu KB P190. Manual - part 862

Engine Management – V6 – Diagnostics

Page 6C1-2–170

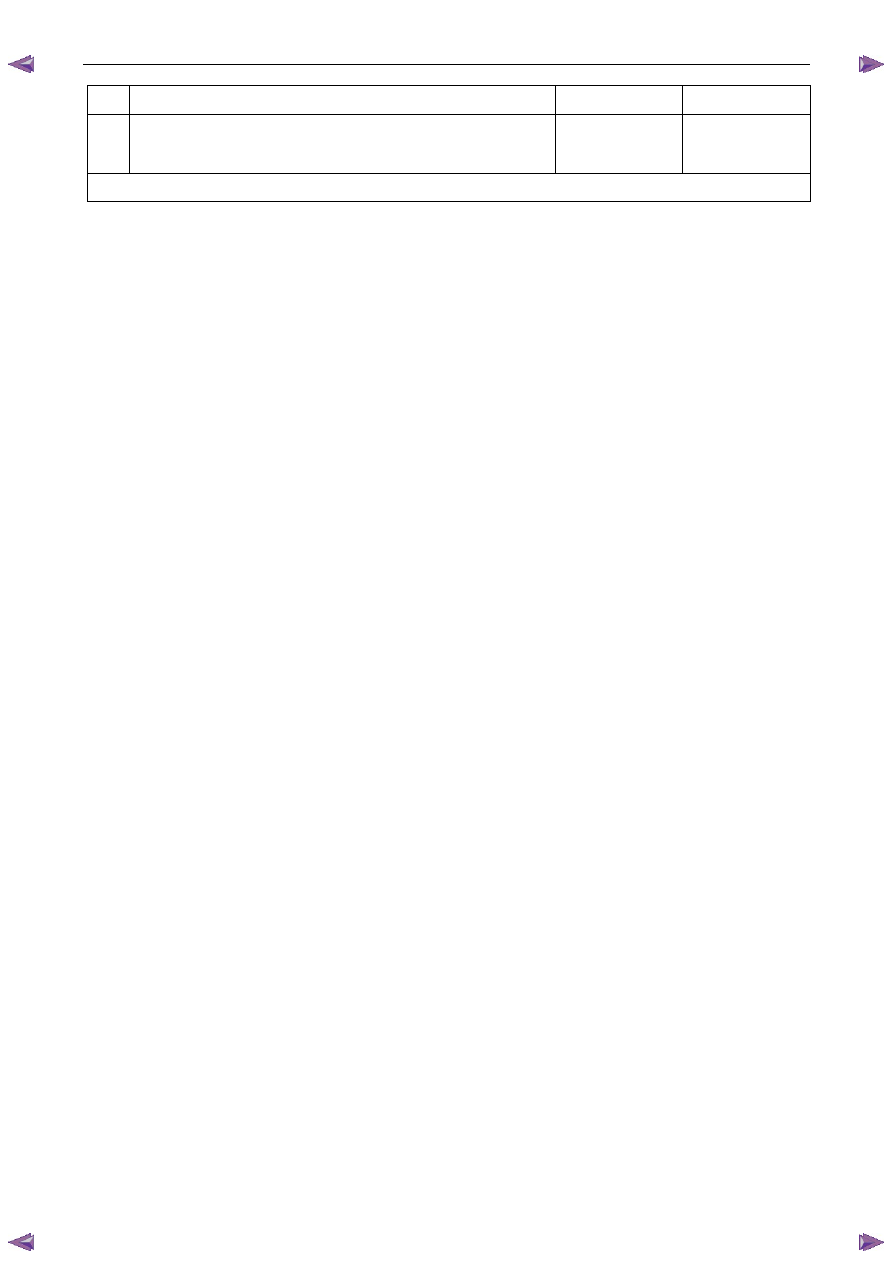

Step Action

Yes

No

7

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.46 DTC P2096 or P2098

DTC Descriptors

This diagnostic procedure supports the following DTCs:

•

DTC P2096 Post Catalyst O2 Sensor Fuel Trim Below Lower Limit (Bank 1)

•

DTC P2098 Post Catalyst O2 Sensor Fuel Trim Below Lower Limit (Bank 2)

Circuit Description

The wide band heated oxygen sensor 1 measures the amount of oxygen in the exhaust system and provides more

information than the switching style HO2S2. The wide band sensor consists of an oxygen sensing cell, an oxygen

pumping cell, and a heater. The exhaust gas sample passes through a diffusion gap between the sensing cell and the

pumping cell. The engine control module (ECM) supplies a voltage to the HO2S and uses this voltage as a reference to

the amount of oxygen in the exhaust system. An electronic circuit within the ECM controls the pump current through the

oxygen pumping cell, maintaining a constant voltage in the oxygen sensing cell. The ECM monitors the voltage variation

in the sensing cell and attempts to keep the voltage constant by increasing or decreasing the amount of current flow, or

oxygen ion flow, to the pumping cell. By measuring the amount of current required to maintain the voltage in the sensing

cell, the ECM can determine the concentration of oxygen in the exhaust. The HO2S voltage is displayed as a lambda

value. A lambda value of 1 is equal to a stoichiometric air fuel ratio of 14.7:1. Under normal operating conditions, the

lambda value will remain around 1. When the fuel system is lean, the oxygen level will be high and the lambda signal

will be high or more than 1. When the fuel system is rich, the oxygen level will be low, and the lambda signal will be low

or less than 1. The ECM uses this information to maintain the correct air / fuel ratio.

Fuel trim biasing is used by the ECM to keep the post catalyst HO2S voltage within a range of 580 – 665 mV as

possible. This allows optimal catalyst efficiency under light load conditions, such as at idle or a steady cruise. The ECM

constantly monitors how lean or rich the fuel trim bias is commanded. If the ECM detects that the fuel trim bias is

commanded lean for more than a calibrated amount, DTC P2096 or P2098 sets.

Conditions for Running the DTC

•

Before the ECM can report DTC P2096 or P2098 failed, DTCs P0030, P0031, P0032, P0041, P0050, P0051,

P0052, P0101, P0131, P0132, P0135, P0137, P0138, P0140, P0141, P0151, P0152, P0155, P0157, P0158,

P0160, P0161, P2231, P2234, P2237, P2240, P2243, P2247, P2251, P2254, P2270, P2271, P2273, P2626, and

P2629 must run and pass.

•

The engine is operating for more than 2 seconds.

•

The post catalyst fuel trim control is enabled.

•

The front and rear HO2S are in Closed Loop.

•

DTCs P2096and P2098 run continuously once the above conditions are met for more than 40 seconds.

Conditions for Setting the DTC

The post catalyst fuel trim correction factor is biased lean by more than 3 percent of the HO2S lambda value for more

than 4 seconds.

Action Taken When the DTC Sets

•

The ECM activates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the

diagnostic runs and fails.

•

The ECM records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the

control module stores this information in the Failure Records. If the diagnostic reports a failure on the second

consecutive ignition cycle, the control module records the operating conditions at the time of the failure. The

control module writes the operating conditions to the Freeze Frame and updates the Failure Records.