Isuzu KB P190. Manual - part 853

Engine Management – V6 – Diagnostics

Page 6C1-2–134

Test Description

The following number refers to the step numbers in the diagnostic table:

3

A fault condition in the stop lamp switch assembly may trigger these DTCs.

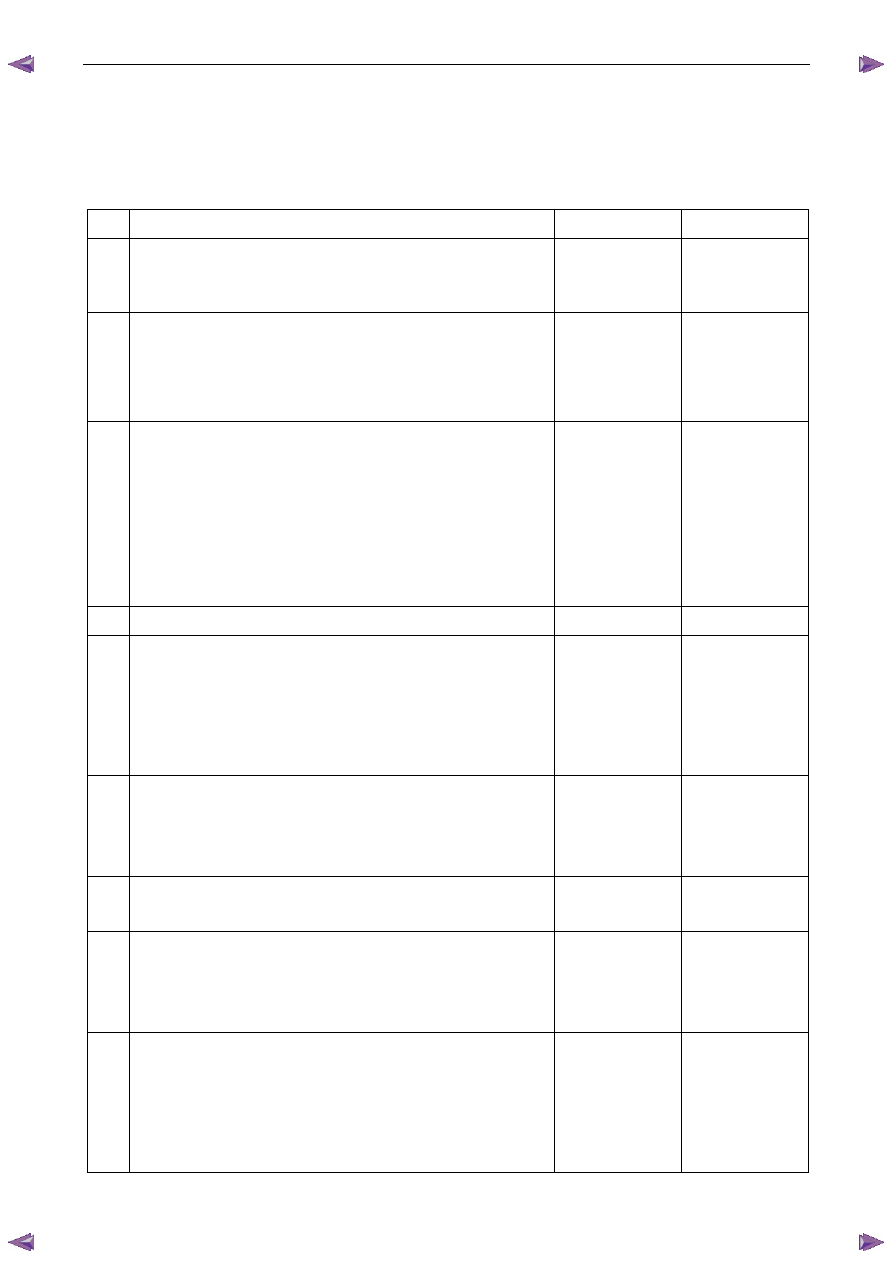

DTC P0504 or P0571 Diagnostic Table

Step Action

Yes

No

1

Has the diagnostic system check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Operate the vehicle within the conditions for running the DTC.

3

Using Tech 2, select the DTC display function.

Does DTC P0504 or DTC P0571 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Ignition ON, engine OFF.

2

On Tech 2 select: Engine / V6 Engine / Data Display / Cruise

Control Data.

3

Observe the status of the brake lamp switch and cruise control

cancel switch.

4

Fully depress the brake pedal.

Does Tech 2 display change from Inactive to Active in all switches

when the pedal is pressed?

Refer to Additional

Information in this

DTC

Go to Step 4

4

Did the brake lamp switch Tech 2 status fail to change?

Go to Step 5

Go to Step 9

5

1

Disconnect the wiring connector from the brake switch

assembly. Refer to 8C Cruise Control.

2 Ignition

ON.

3

Connect a test lamp between the voltage circuit of the stop

lamp switch and a good ground.

Does the test lamp illuminate?

Go to Step 7

Go to Step 6

6

1

Repair the high resistance or open circuit fault condition in the

voltage circuit of the stop lamp switch. Refer to 8A Electrical -

Body and Chassis for information on electrical wiring repair

procedures.

Was the repair completed?

Go to Step 14

—

7

1

Test the stop lamp switch. Refer to 8C Cruise Control – HFV6.

Was any fault found and rectified?

Go to Step 14

Go to Step 8

8

1

Test the control circuit of the stop lamp switch for a high

resistance, open circuit, short to ground or short to voltage fault

condition. Refer to 8A Electrical - Body and Chassis for

information on electrical fault diagnosis.

Was the repair completed?

Go to Step 14

Go to Step 13

9

1

Disconnect the wiring connectors from the brake switch

assembly. Refer to 8C Cruise Control – HFV6.

2 Ignition

ON.

3

Connect a test lamp between the voltage circuit of the cruise

control cancel switch and a good ground.

Does the test lamp illuminate?

Go to Step 11

Go to Step 10