Isuzu KB P190. Manual - part 835

Engine Management – V6 – Diagnostics

Page 6C1-2–62

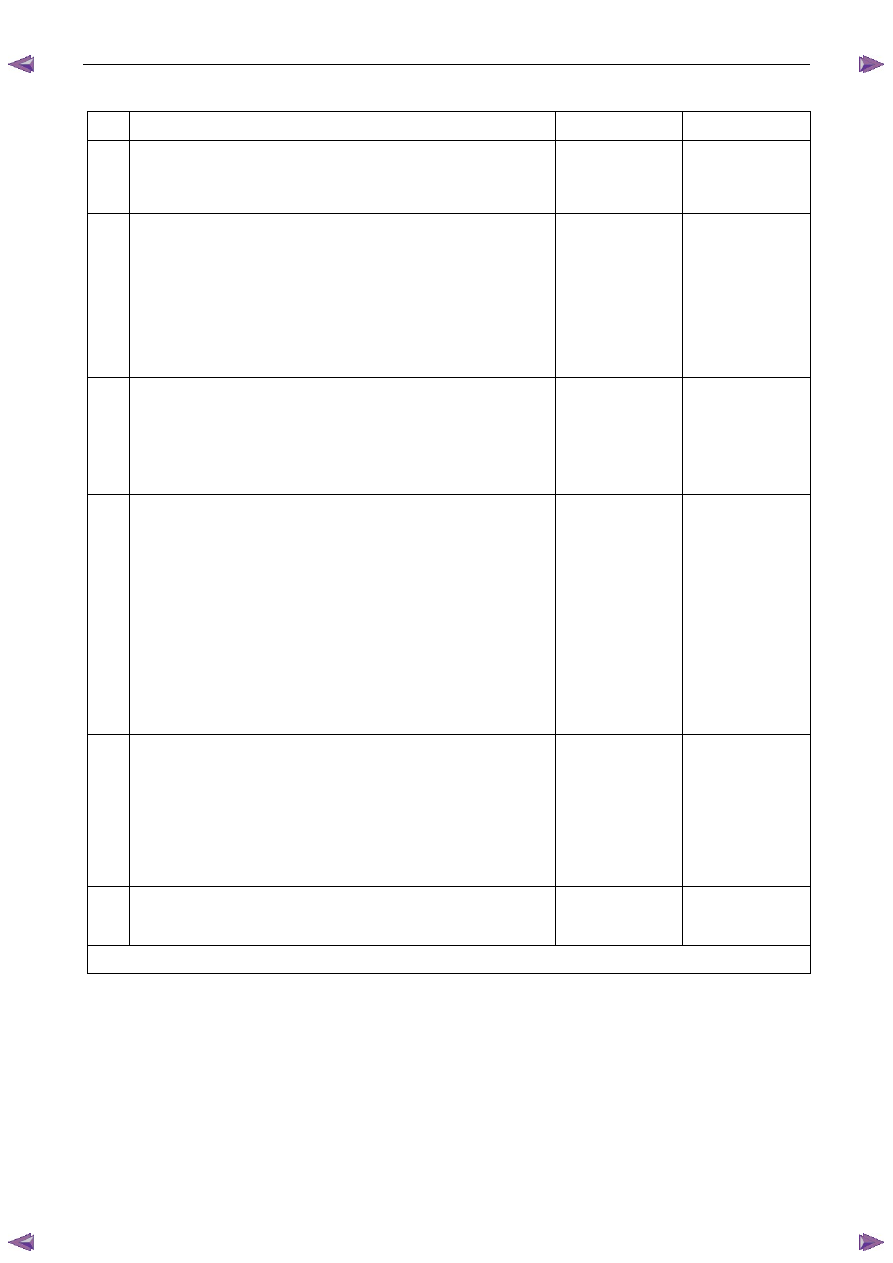

DTC P0008, P0009 or P0016 Diagnostic Table

Step Action

Yes

No

1

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check in

this Section

2

1

Switch off the ignition for 30 seconds.

2

Start the engine.

3

Allow the engine to reach the normal operating temperature.

4

Increase the engine speed to 2,000 rpm for 10 seconds.

5

Using Tech 2, select the DTC display function.

Does DTC P0008, P0009 or P0016 fail this ignition cycle?

Go to Step 3

Refer to Additional

Information in this

DTC

3

1

Are DTCs relating to the following DTCs also set:

•

Camshaft actuator circuit

•

CMP sensor circuit

•

CKP sensor circuit

Go to the

appropriate DTC

Table in this Section

Go to Step 4

4

1

Inspect the engine for the following fault conditions. Refer to

6A1 Engine Mechanical – V6:

•

incorrect installation of the CMP sensor,

•

incorrect installation of the CKP sensor,

•

timing chain tensioner fault condition,

•

incorrectly installed timing chain,

•

excessive play in the timing chain, and

•

timing chain that jumped teeth.

Was any fault found and rectified?

Go to Step 5

Refer to Additional

Information in this

DTC

5

1

Using Tech 2, clear the DTCs.

2

Switch off the ignition for 30 seconds.

3

Start the engine.

4

Operate the vehicle within the conditions for running the DTC.

Does any of the crankshaft / camshaft position correlation DTCs fail

this ignition cycle?

Go to Step 2

Go to Step 6

6

Using Tech 2, select the DTC display function.

Does Tech 2 display any DTCs?

Go to the

appropriate DTC

Table in this Section

System OK

When all diagnosis and repairs are completed, check the system for correct operation.

7.3

DTC P0030, P0031, P0032, P0036, P0037,

P0038, P0050, P0051, P0052, P0056,

P0057 or P0058

DTC Descriptor

This diagnostic procedure supports the following DTCs:

•

DTC P0030 – O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1)

•

DTC P0031 – O2 Sensor Heater Circuit Low Voltage (Bank 1, Sensor 1)