Isuzu KB P190. Manual - part 825

Engine Management – V6 – Diagnostics

Page 6C1-2–22

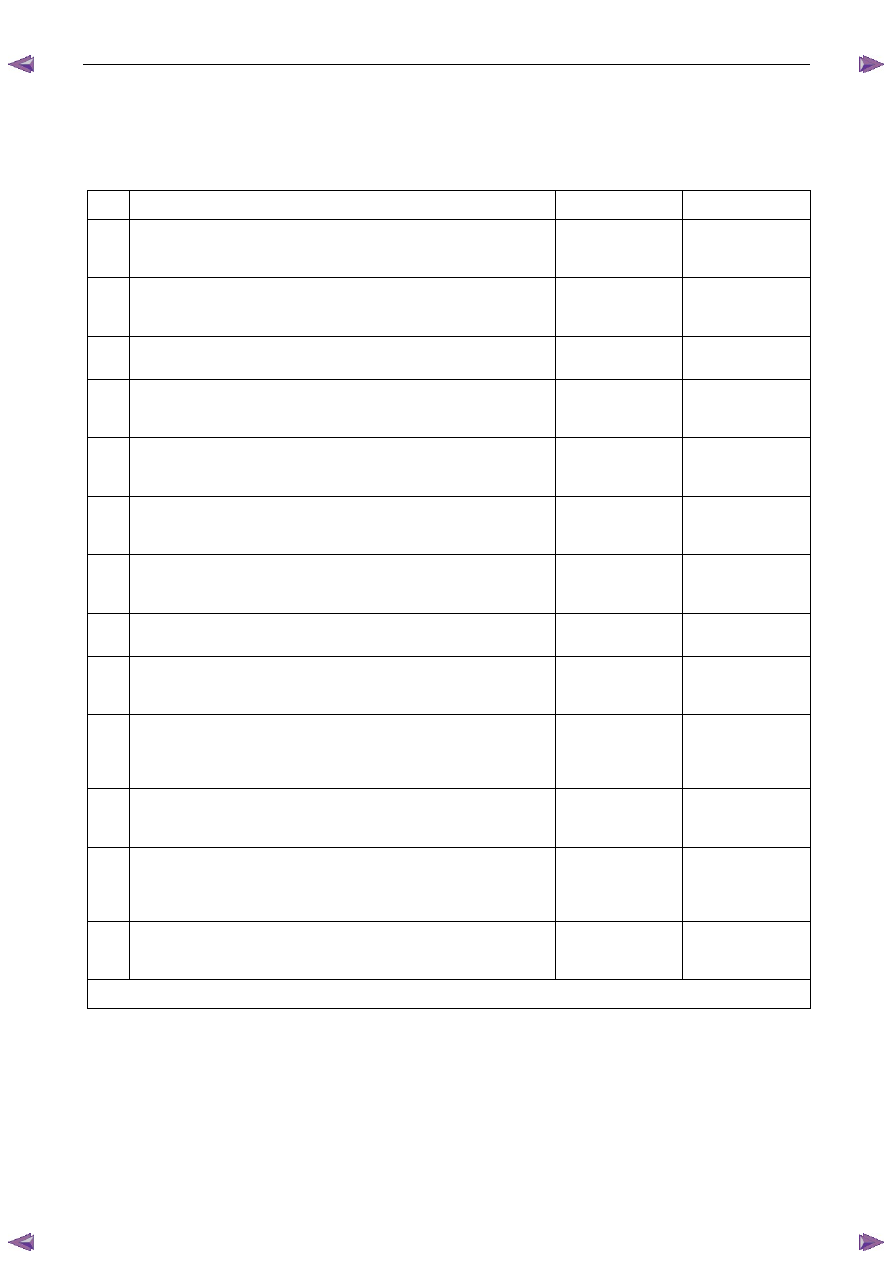

5 Symptoms

Diagnostics

5.1

Symptoms Diagnosis Table

Step Action

Yes

No

1

Has the Diagnostic System Check been performed?

Go to Step 2

Refer to

4.4 Diagnostic

System Check

2

Is the fault intermittent?

Refer to

5.2 Intermittent

Fault Conditions

Go to Step 3

3

Does the engine backfire?

Refer to

5.3 Backfire

Go to Step 4

4

Does the engine crank but does not run?

Refer to

5.4 Cranks

But

Does Not Run

Go to Step 5

5

Does the engine cut-out or miss?

Refer to

5.5 Cuts

Out,

Misses

Go to Step 6

6

Is there a detonation or spark knock noise coming from the engine?

Refer to

5.6 Detonation /

Spark Knock

Go to Step 7

7

Is there an engine dieseling or run-on condition?

Refer to

5.7 Dieseling,

Run-on

Go to Step 8

8

Is there an engine hard starting condition?

Refer to

5.8 Hard

Start

Go to Step 9

9

Is there an engine hesitation, sag or stumble condition?

Refer to

5.9 Hesitation,

Sag and Stumble

Go to Step 10

10 Does the engine suffer from lack of power, sluggishness or

sponginess?

Refer to

5.10 Lack of Power,

Sluggishness or

Sponginess

Go to Step 11

11 Does the engine suffer from poor fuel economy?

Refer to

5.11 Poor

Fuel

Economy

Go to Step 12

12 Does the engine suffer from rough, unstable or incorrect idle and

engine stalling?

Refer to

5.12 Rough,

Unstable, Incorrect

Idle or Stalling

Go to Step 13

13 Does the engine surge or chuggle?

Refer to

5.13 Surges

/

Chuggles

Go to Step 14

When all diagnosis and repairs are completed, check the system for correct operation.

5.2

Intermittent Fault Conditions

Description

A fault condition is intermittent if one of the following conditions exists:

•

the fault condition is not always present,

•

the fault condition cannot be presently duplicated, or