Isuzu KB P190. Manual - part 773

Engine Mechanical – V6

Page 6A1–315

Page 6A1–315

20

Rotate the driver installation tool until the mark (1) on

the driver installation tool aligns with the top of the

drill bushing (2).

21

Inspect the insert for correct installation into the

tapped hole.

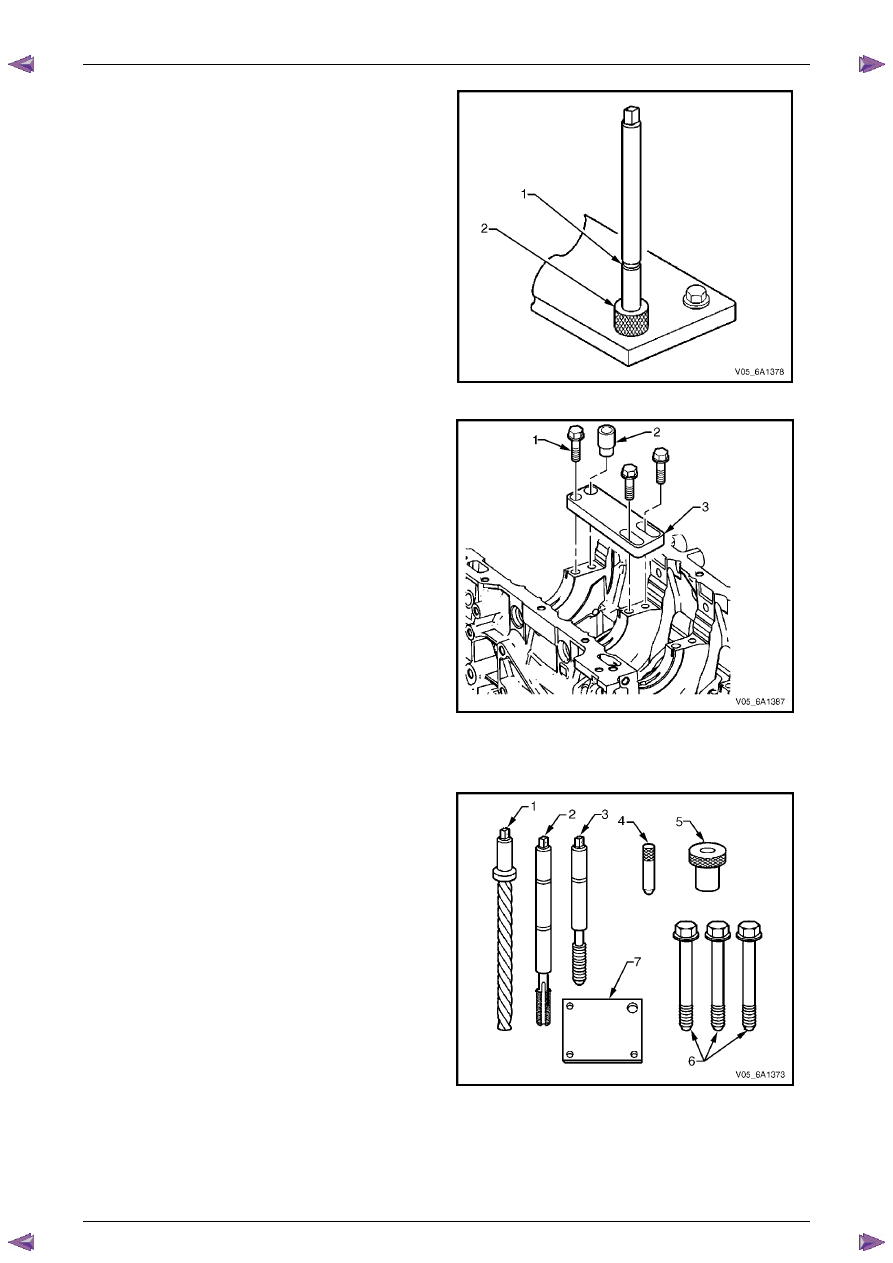

Figure 6A1 – 586

22

Remove the fixture plate bolts (1), bushing (2) and

fixture plate (3).

Figure 6A1 – 587

Cylinder Head Bolt Hole Thread Repair

The cylinder head bolt hole thread repair tools are in Tool

No. J 42385-2000 and J 42385-700 which consist of the

following:

•

Drill (1) J 42385-723

•

Tap (2) J 42385-724

•

Installation driver (3) J 42385-725

•

Alignment pin (4) J 42385-303

•

Bushing (5) J 42385-302

•

Bolts (6) J 42385-733

•

Fixture plate (7) J 42385-401

Figure 6A1 – 588