Isuzu KB P190. Manual - part 761

Engine Mechanical – V6

Page 6A1–267

Page 6A1–267

CAUTION

Do not damage the crankshaft journal,

cylinder wall and piston cooling jets when

removing the connecting rod and piston

assembly.

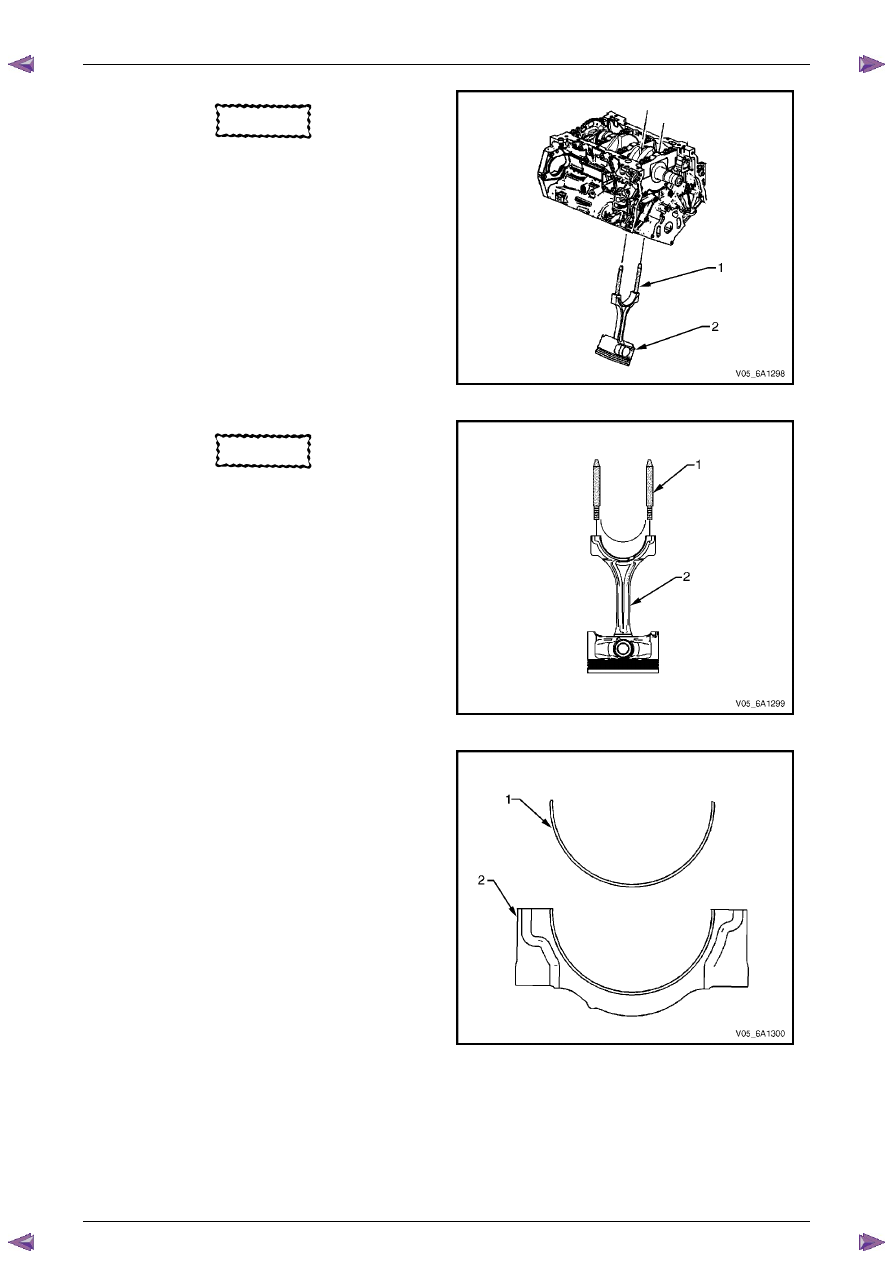

12

Using connecting rod guide pin set, Tool No.

EN-46121 (1), push the connecting rod and piston

assembly (2) through the top of the cylinder.

Figure 6A1 – 467

CAUTION

When dismantled, ensure the connecting

rod, connecting rod cap, piston and

bearings are organised in their original

position and location. This will also aid

engine mechanical diagnosis.

13

Remove connecting rod guide pin set, Tool No.

EN-46121 (1) from the connecting rod bolt holes.

14

Remove the upper connecting rod bearing from the

connecting rod (2).

Figure 6A1 – 468

15

Remove the lower connecting rod bearing (1) from

the connecting rod cap (2).

Figure 6A1 – 469