Isuzu KB P190. Manual - part 751

Engine Mechanical – V6

Page 6A1–227

Page 6A1–227

2

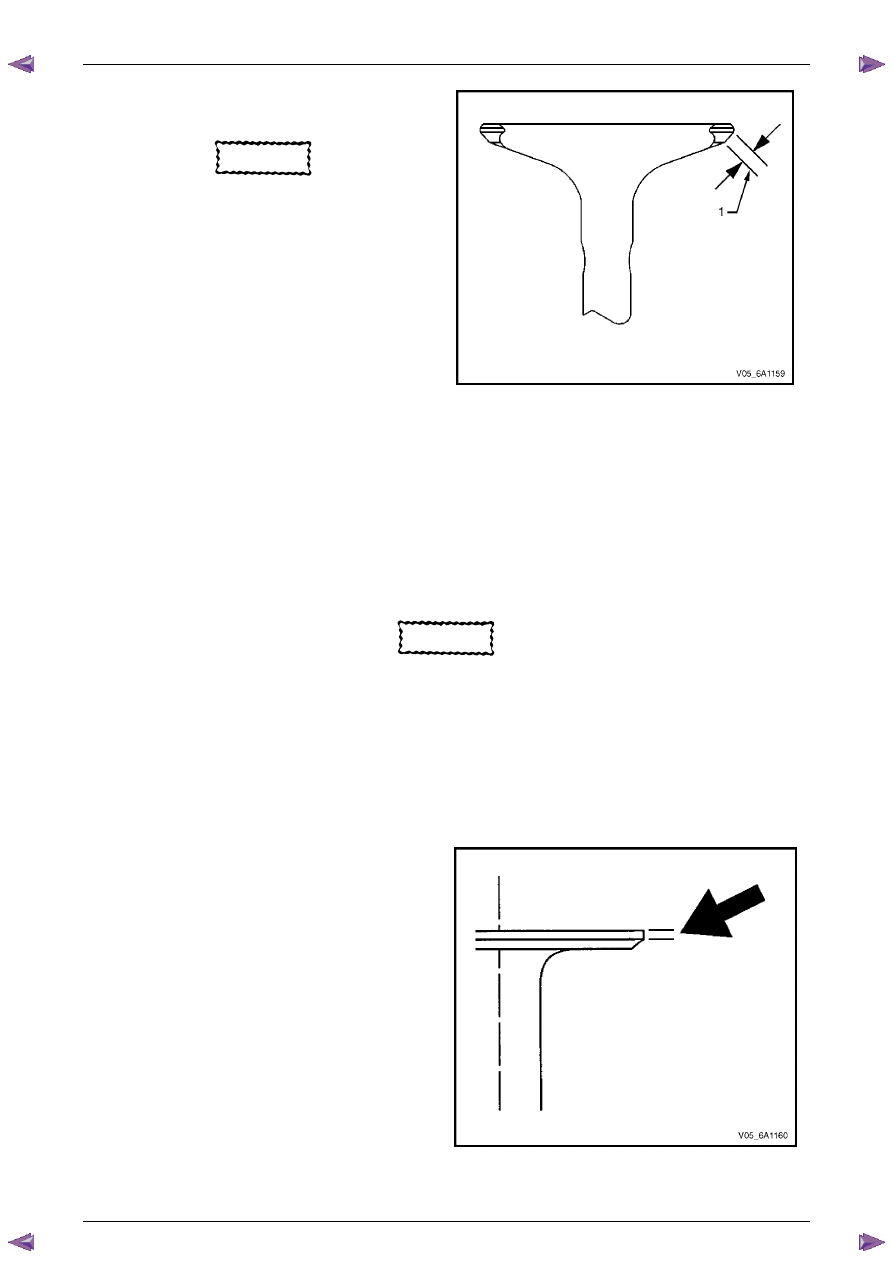

Measure the seat width on the valve face (1) using a

correct scale.

CAUTION

The seat contact area must be at least

0.5 mm from the outer diameter (margin) of

the valve. If the contact area is too close to

the margins, the seat must be reconditioned

to move the contact area away from the

margin.

3

Compare the measurements with the specifications,

refer to

5 Specifications

.

4

If the seat widths are acceptable, check the valve

seat roundness, refer to Valve Seat Roundness

Measurement Procedure in this Section.

5

If the seat width is not acceptable, grind the valve

seat to bring the width back to specification. Correct

valve seat width is critical to providing the correct

amount of valve heat dissipation, refer to Valve and

Seat Reconditioning Procedure in this Section.

Figure 6A1 – 383

Valve Seat Roundness Measurement Procedure

1

Measure the valve seat roundness using a dial indicator attached to a tapered pilot installed in the guide. The pilot

should have a slight bind when installed in the guide.

CAUTION

The correct size pilot must be used. Do not

use adjustable diameter pilots. Adjustable

pilots may damage the valve guides.

2

Compare your measurements with the specifications, refer to

5 Specifications

.

3

If the valve seat exceeds the roundness specification, grind the valve and valve seat, refer to Valve and Seat

Reconditioning Procedure in this Section.

4

If new valves are being used, the valve seat roundness must be within 0.05 mm.

Valve Margin Measurement Procedure

1

Measure the valve margin using an appropriate scale.

2 Refer

to

5 Specifications

for minimum valve margin

and compare them to your measurements.

3

If the valve margins are beyond specification, replace

the valves.

4

If the valve margins are within specification and do

not require refacing, test the valve for seat

concentricity, refer to Valve-to-Seat Concentricity

Measurement Procedure in this Section.

Figure 6A1 – 384