Isuzu KB P190. Manual - part 704

Engine Mechanical – V6

Page 6A1–39

Page 6A1–39

2.9

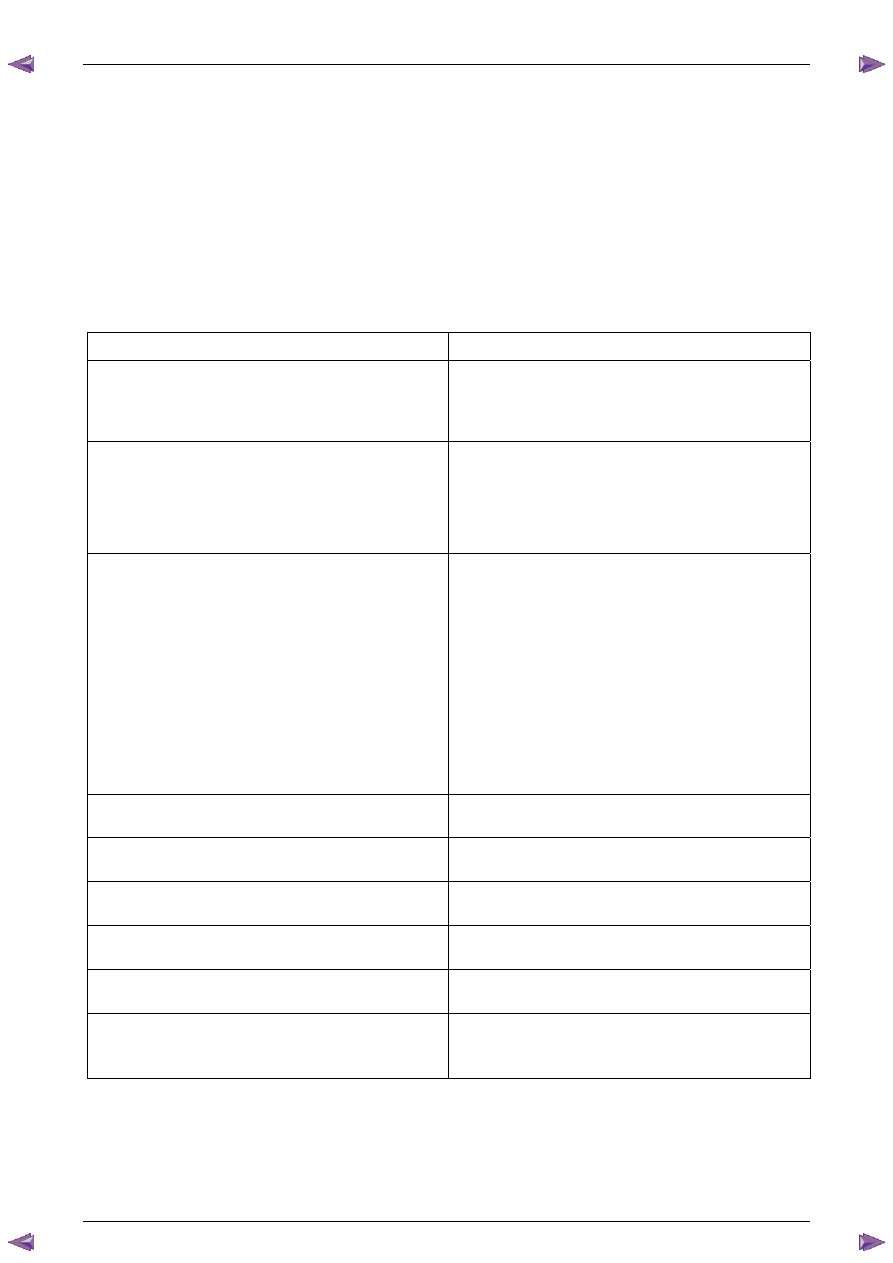

Upper Engine Noise, Regardless of

Engine Speed

N O T E

A cold piston knock, which disappears in

approximately 1.5 minutes from start up, should

be considered acceptable. A cold engine knock

usually disappears when the specific cylinder’s

secondary ignition circuit is grounded out during

diagnosis.

A light rattle/tapping noise may indicate a valve train/upper engine concern, while a low rumble/knocking may indicate a

crankshaft, piston or lower engine concern.

Cause Correction

Low oil pressure.

1

Perform an oil pressure test, refer to 2.19 Engine Oil

Pressure Diagnosis.

2

Repair or replace the engine oil pump as required,

refer to 3.17 Oil Pump Assembly.

Worn or loose stationary hydraulic lash adjusters (SHLA)

and/or valve rocker arms.

The SHLAs, rocker arm and roller bearings should be intact

and in the correct position.

1

Clean, inspect and replace the camshaft lash

adjusters as required, refer to 3.21 Stationary

Hydraulic Lash Adjuster.

2

Replace the SHLAs and/or rocker arms as required,

refer to 3.21 Stationary Hydraulic Lash Adjuster or

3.20 Rocker Arm.

Incorrect lubrication to the stationary hydraulic lash

adjusters and valve rocker arm.

Inspect the following components and repair or replace as

required:

•

valve rocker arms, refer to 3.20 Rocker Arm.

•

stationary hydraulic lash adjusters, refer to 3.21

Stationary Hydraulic Lash Adjuster.

•

oil filter by-pass valve, refer to 3.3 Oil Filter Adaptor.

•

oil pump and suction pipe, refer to 3.17 Oil Pump

Assembly.

•

cylinder head oil galleries, refer to 3.22 Cylinder

Head Assembly.

•

cylinder block oil galleries, refer to 4.7 Cylinder

Block.

Broken Valve Spring.

Replace the valve spring, refer to 3.22 Cylinder Head

Assembly.

Stretched or broken timing chain/s and/or damaged timing

chain sprocket teeth.

Replace the timing chains or sprockets as required, refer to

3.16 Timing Chains, Tensioners, Shoes and Guides.

Worn or faulty timing chain tensioner or guide.

Replace the timing chains or sprockets as required, refer to

3.16 Timing Chains, Tensioners, Shoes and Guides.

Worn camshaft lobes.

Replace the camshaft/s and SHLAs as required, refer to

3.19 Camshaft or 3.21 Stationary Hydraulic Lash Adjuster.

Worn valve guides and/or valve stems.

Inspect and repair or replace valves and valve guides as

required, refer to 3.22 Cylinder Head Assembly.

Stuck valves.

Carbon on the valve stem or valve seat may cause the

valve to stay open.

Inspect and repair or replace valves and valve guides as

required, refer to 3.22 Cylinder Head Assembly.