Isuzu KB P190. Manual - part 699

Engine Mechanical – V6

Page 6A1–19

Page 6A1–19

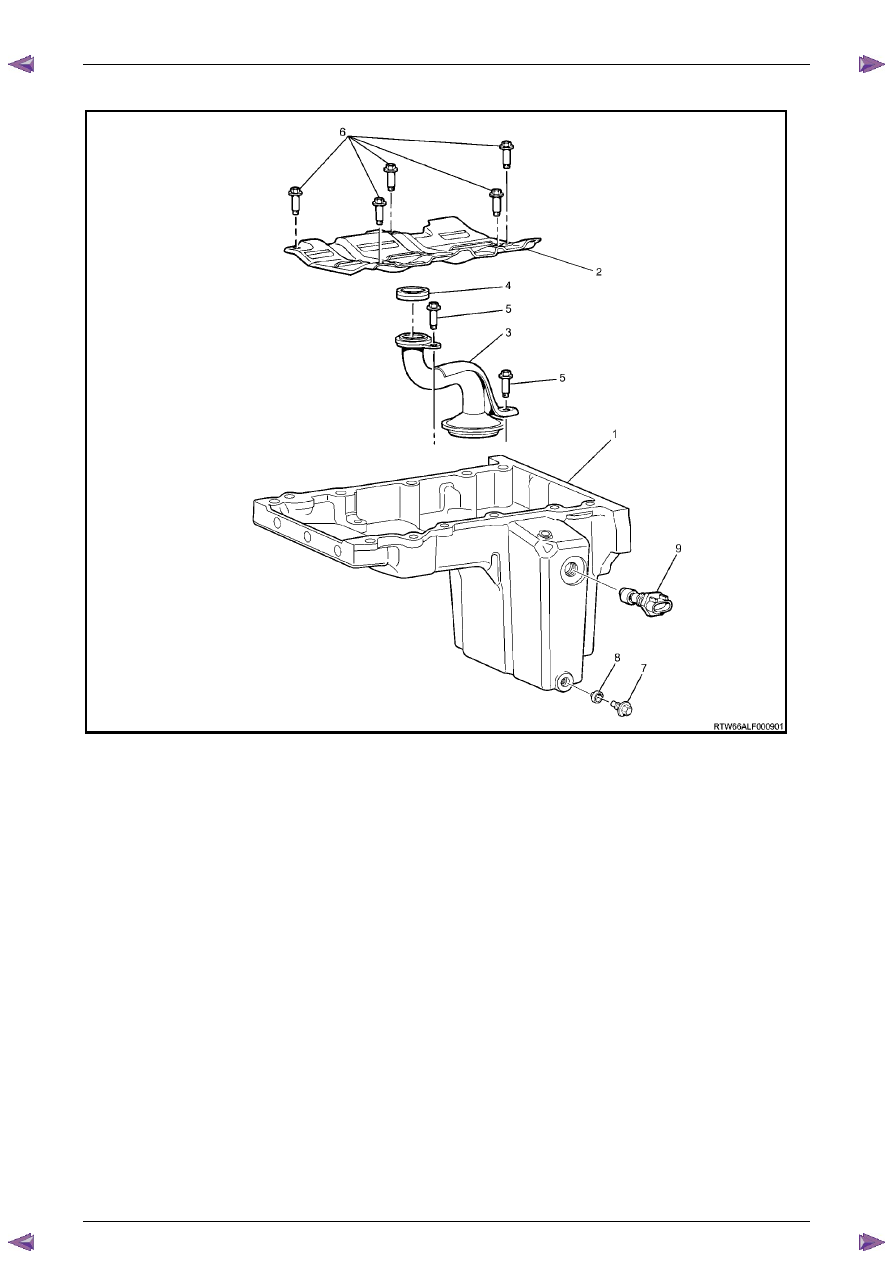

Oil Pan Assembly

Figure 6A1 – 11

Legend

1 Oil

Pan

2

Crankshaft Oil Deflector

3

Oil Pump Suction Pipe

4

Oil Pump Suction Pipe Gasket

5

Oil Pump Suction Pipe Bolt

6

Crankshaft Oil Deflector Bolt

7

Oil Pan Drain Plug

8

Oil Pan Drain Plug Sleeve

9

Engine Oil Level Sensor