Isuzu KB P190. Manual - part 677

Engine Mechanical – V6

Page 6A1–229

3

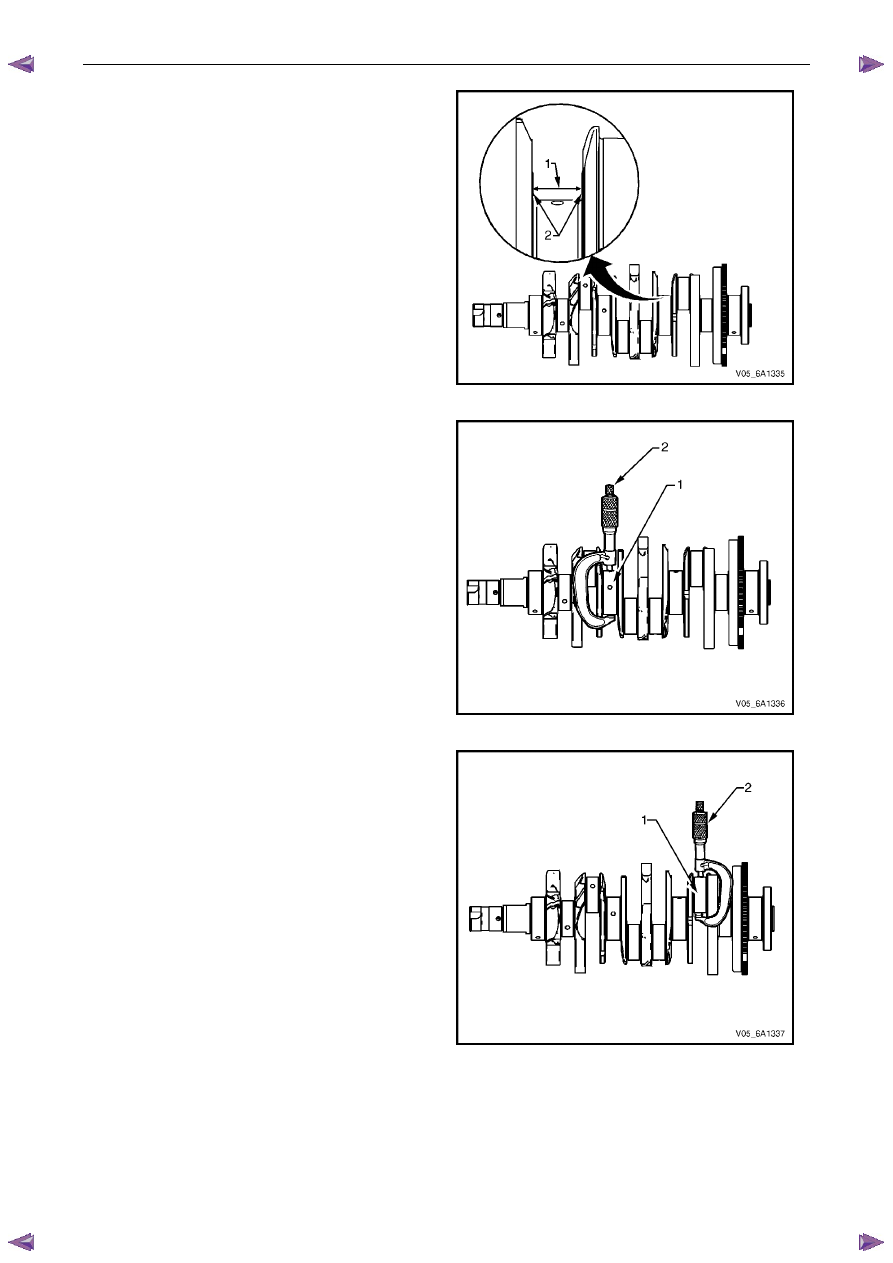

Measure the crankshaft thrust wall width (1) for wear

using an inside micrometer and compare with the

engine specifications, refer to 5

Specifications.

4

Measure the crankshaft thrust wall surface (2) for

runout using a dial indicator, mounted to a magnetic

stand and compare with the engine specifications,

refer to 5

Specifications.

5

If the crankshaft journals are damaged or worn

beyond specifications, the crankshaft may be ground

0.25 mm. There is only one size of oversized main

bearings available for service.

Figure 6A1 – 422

6

Inspect the crankshaft main journals (1) for undersize,

using an outside micrometer (2).

Figure 6A1 – 423

7

Inspect the crankpins (1) for undersize using an

outside micrometer (2).

8

Compare your measurements with those listed in the

engine specifications, refer to 5

Specifications.

If the crankpin journals are worn beyond the

specifications, the crankshaft may be ground 0.25

mm. Only one size of oversized connecting rod

bearings available for service.

Figure 6A1 – 424