Isuzu KB P190. Manual - part 673

Engine Mechanical – V6

Page 6A1–213

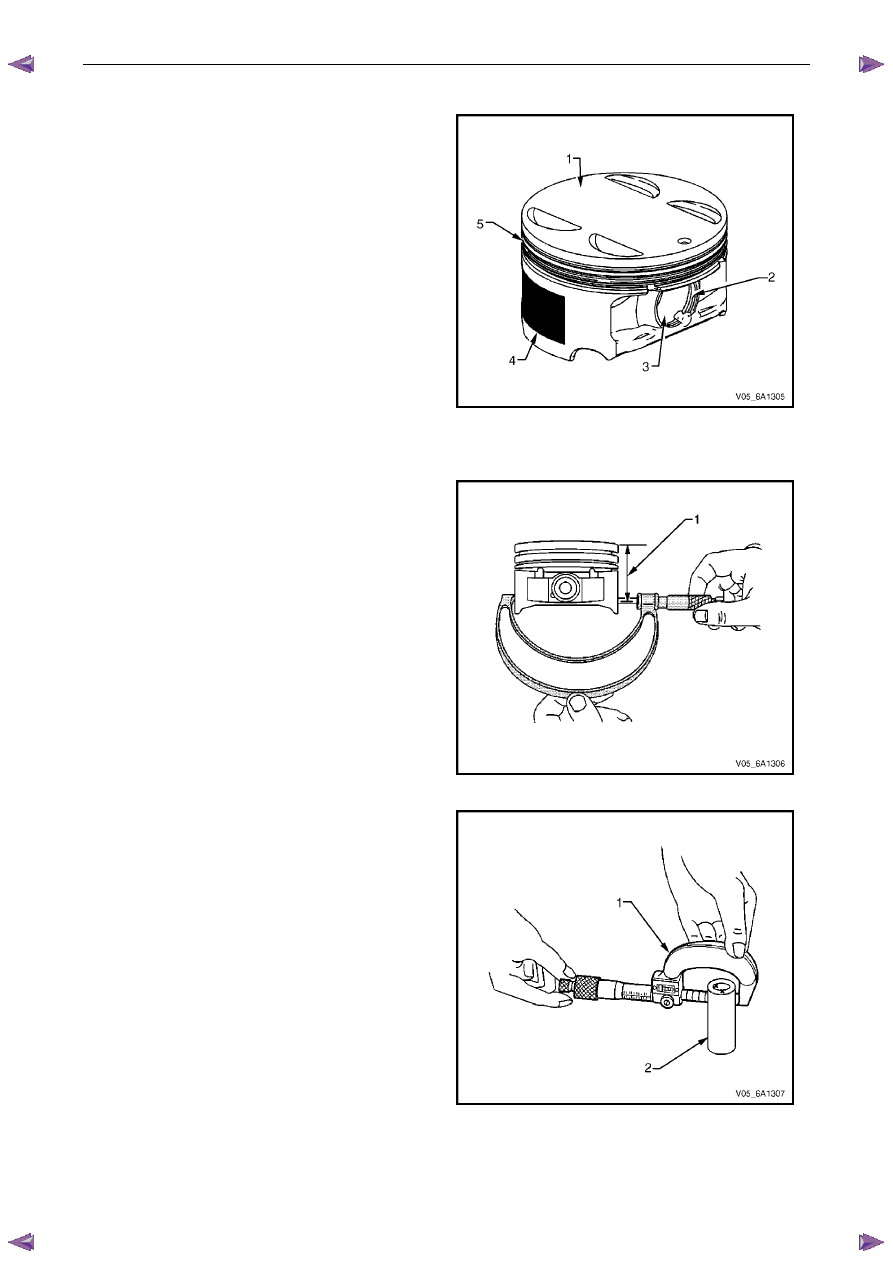

Piston Inspection Procedure

1

Inspect the pistons for the following conditions:

•

eroded areas at the top of the piston (1),

•

piston pin retainer grooves for burrs (2),

•

worn piston pin bores or worn piston pins (3),

•

scuffed or damaged skirt coating (4),

•

ring grooves for cracks, nicks or burrs that may

cause binding (5), and

•

warped or worn ring lands.

2

Replace pistons that show any signs of damage or

excessive wear.

Figure 6A1 – 384

Piston Measurement

1

Measure piston width using the following procedure:

a

Using an outside micrometer, measure the

width of the piston at 30 mm below the crown

top (1), at the thrust surfaces of the piston,

perpendicular to the piston pin centreline.

b

Compare the measurement of the piston to its

original cylinder by subtracting the piston width

from the cylinder diameter.

c

Check your measurements with specifications,

refer to 5

Specifications.

d

If the clearance obtained through measurement

is greater than the provided specifications and

the cylinder bores are within specification,

replace the piston.

Figure 6A1 – 385

2

Measure the piston pin bore to piston pin (2)

clearances using the following procedure:

a

Piston pin bores and pins must be free of

varnish or scuffing.

b

Use an outside micrometer (1) to measure the

piston pin in the piston contact areas.

Figure 6A1 – 386