Isuzu KB P190. Manual - part 646

Engine Mechanical – V6

Page 6A1–105

11

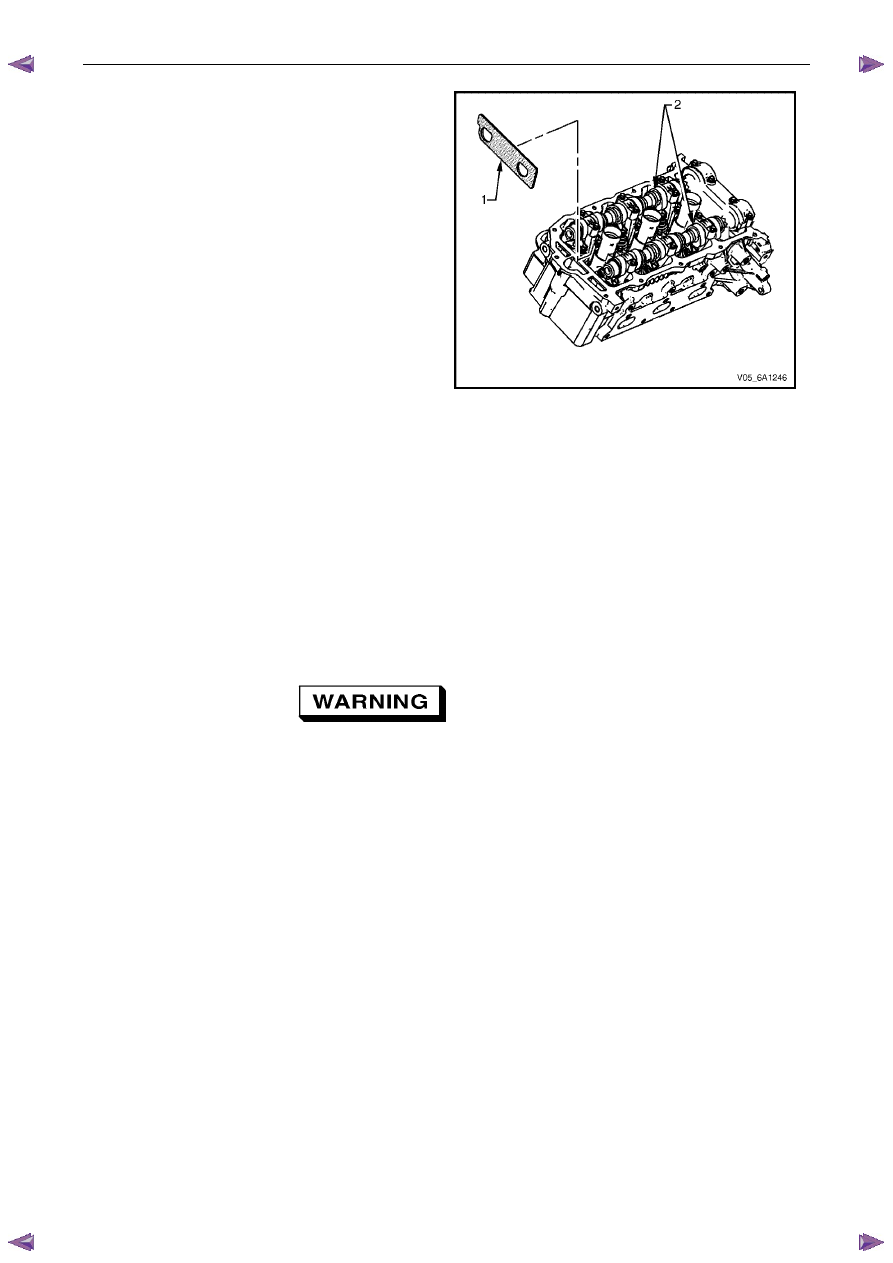

Remove Tool No. EN 46105-1 (1) from the right-hand

cylinder head camshafts (2).

Figure 6A1 – 127

Clean

1

Clean all the following components with a suitable solvent:

•

crankshaft sprocket,

•

primary timing chain,

•

primary timing chain guide,

•

primary timing chain tensioner,

•

secondary timing chains,

•

secondary timing chain shoes,

•

secondary timing chain guides,

•

secondary timing chain tensioners, and

•

bolts.

Safety glasses must be worn when using

compressed air.

2

Dry all the components with compressed air.