Isuzu KB P190. Manual - part 529

6B-12 ENGINE COOLING

Inspection

Radiator Cap

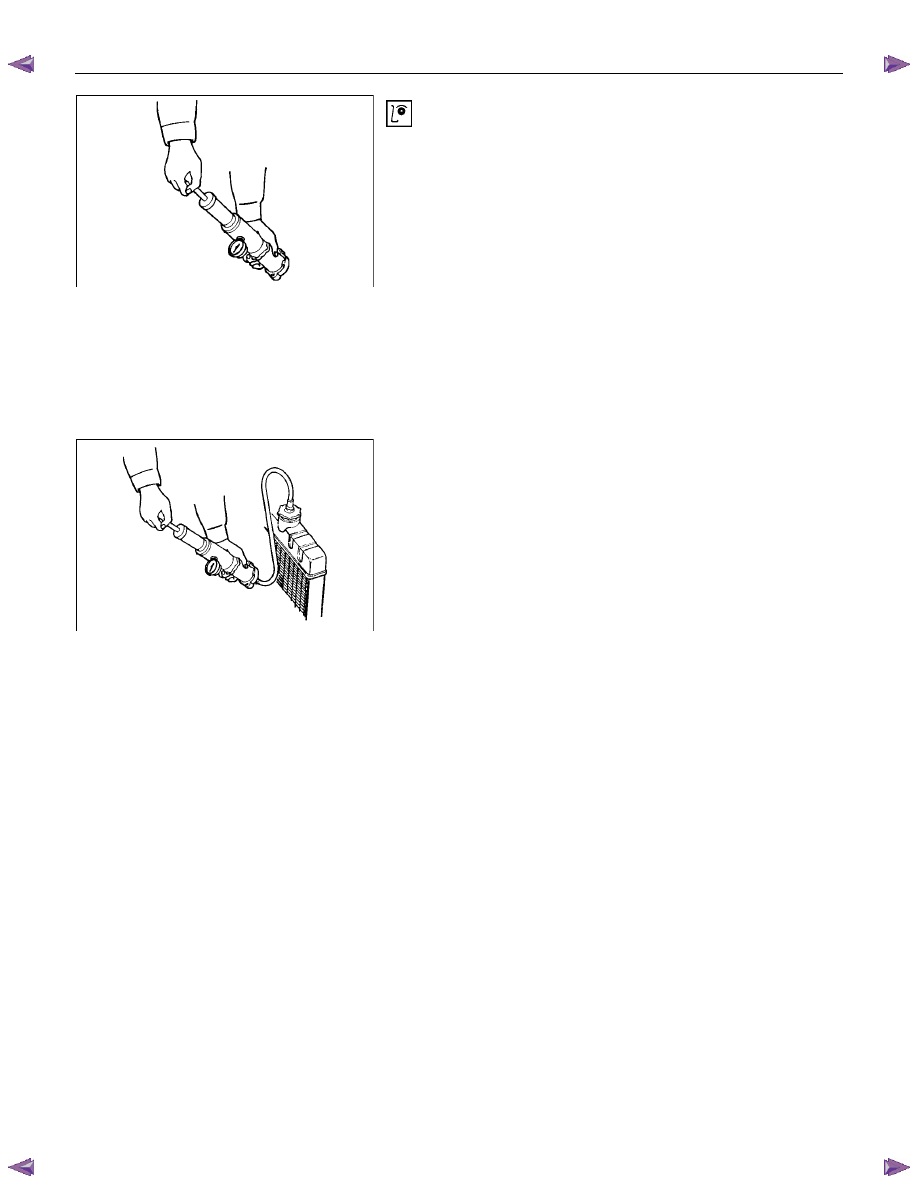

Measure the valve opening pressure of the pressurizing valve

with a radiator filler cap tester.

Replace the cap if the valve opening pressure is outside the

standard range.

Valve opening pressure kPa (psi) 88.3 – 103.0

(13.5 – 15.7)

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0

Check the condition of the vacuum valve in the center of the

valve seat side of the cap. If considerable rust or dirt is found,

or if the valve seat cannot be moved by hand, clean or replace

the cap.

Valve opening vacuum kPa (psi) 1.9 - 4.9

(0.28 - 0.71)

Radiator Core

1. A bent fin may result in reduced ventilation and overheating

may occur. All bent fins must be straightened. Pay close

attention to the base of the fin when it is being straightened.

2. Remove all dust, bugs and other foreign material.

Flushing the Radiator

Thoroughly wash the inside of the radiator and the engine

coolant passages with cold water and mild detergent. Remove

all sign of scale and rust.

Cooling System Leakage Check

Use a radiator cap tester to force air into the radiator through

the filler neck at the specified pressure of 196 kPa (28.5 psi)

with a cap tester:

• Leakage from the radiator

• Leakage from the coolant pump

• Leakage from the water hoses

• Check the rubber hoses for swelling.

Cap tester: 5-8840-0277-0

Adapter: 5-8840-2603-0