Isuzu KB P190. Manual - part 525

6A-86 ENGINE MECHANICAL (C24SE)

Con-rod

Permissible, weight variation of con-rods without pistons and bearing shells within an engine 8 g.

As the con-rods have no counterweights, re-working is not possible.

Con-rods must be replaced only as a set.

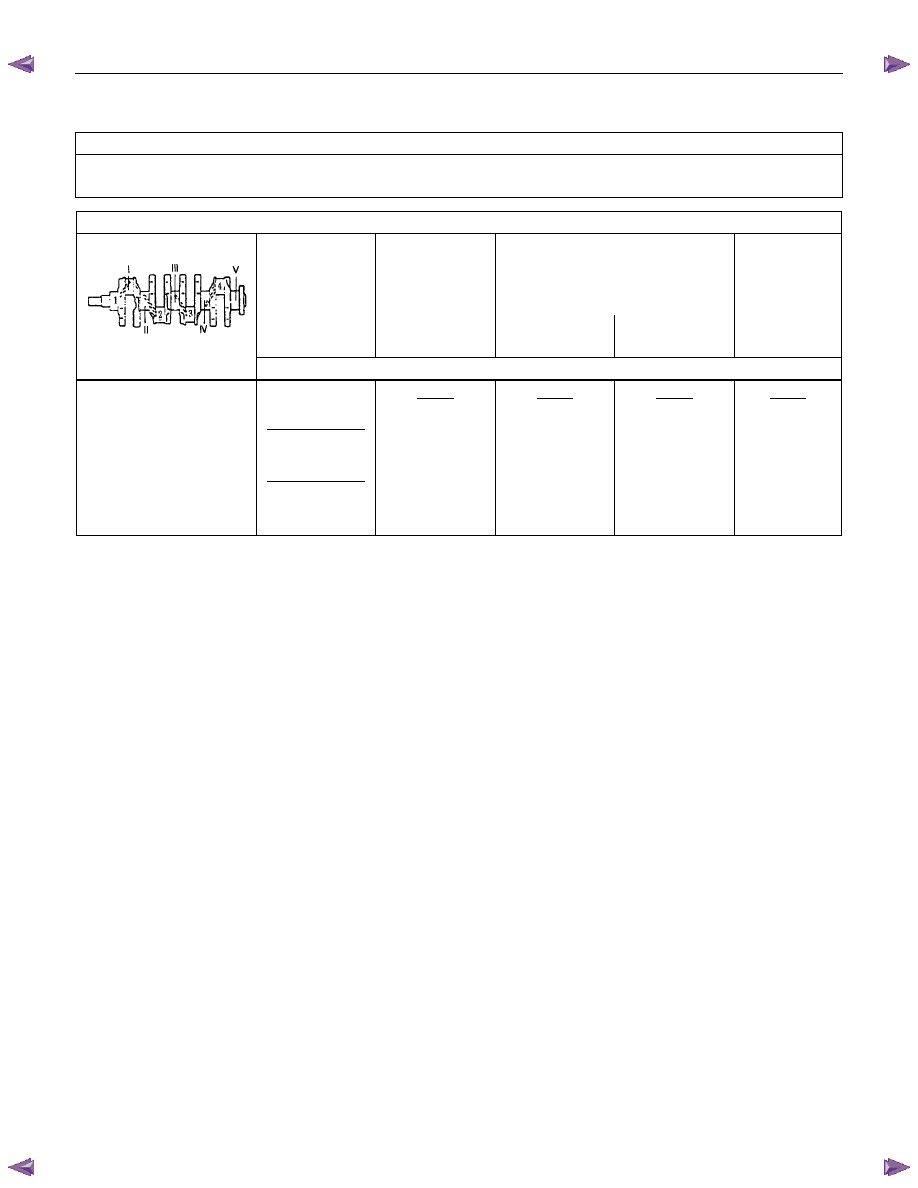

Crankshaft Grinding Dimensions

Crankshaft

bearing journals

I, II, III, IV, V

Guide bearings

III

Con-Rod bearing journals

1 to 4

Con-rod

diameter

in

mm/colour code

width

in mm

diameter

in mm

width

in mm

width

in mm

Standard Size for Production and Service

from 57.974

white

to 57.981

over 57.981

green

to 57.988

over 57.988

brown

to 57.995

26.002

25.950

48.988

48.970

26.580

26.450

26.390

26.338

Crankshaft, Cylinder Block (continued)

Crankshaft and con-rod journal Permissible out-of-round:

0.04mm

Out-of-round

Permissible variation of

middle crankshaft bearing

journal when seating shaft into

cylinder block: 0.03mm

Permissible end play

0.05 to 0.152mm

Permissible main bearing play Bearing I to V0.015 to

0.04mm

Permissible con-rod play

0.006 to 0.031mm

Permissible con-rod and play

0.07 to 0.24mm