Isuzu KB P190. Manual - part 503

6-12 ENGINE DIAGNOSIS (C24SE)

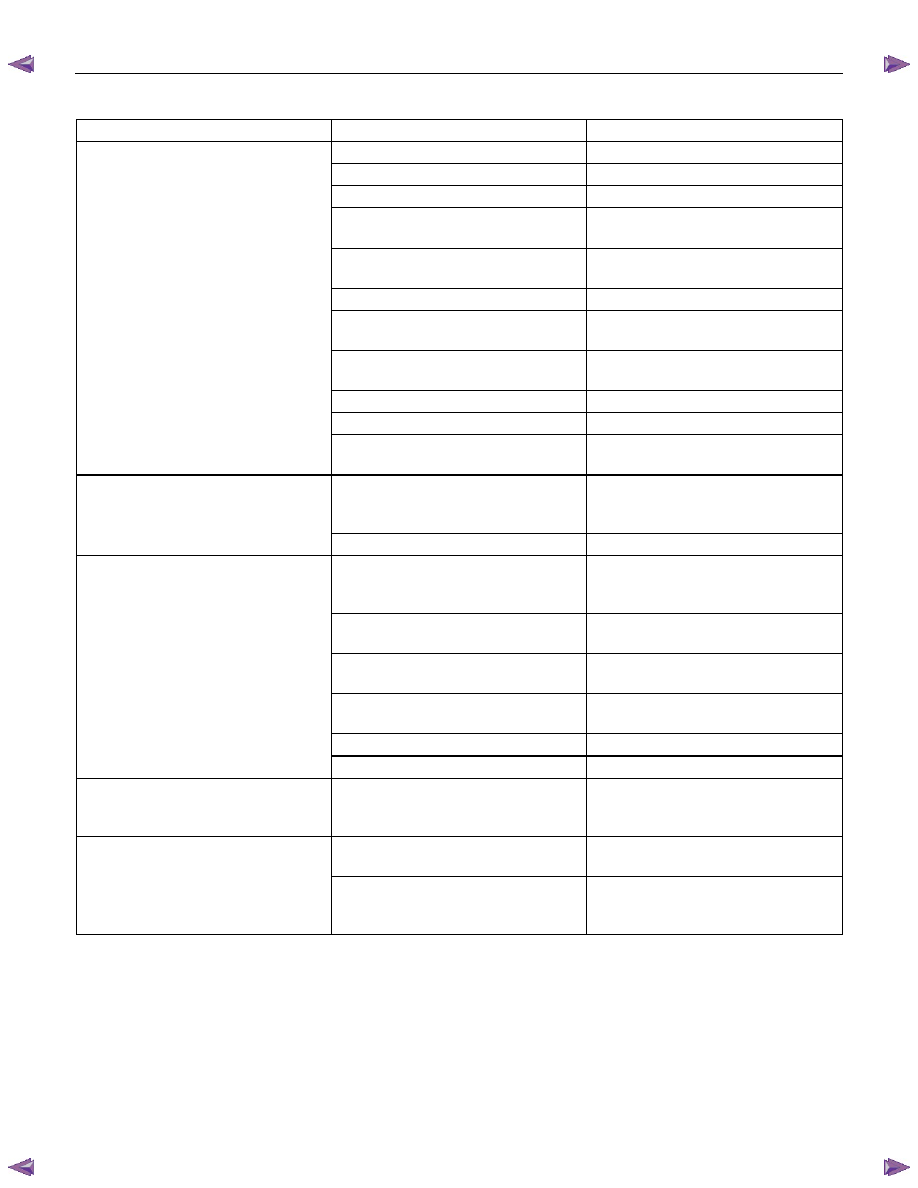

Engine Oil Consumption Excessive

Condition Possible

cause Correction

Oil leaking

Oil pan drain plug loose

Retighten or replace gasket

Oil pan setting bolds loosened

Retighten

Oil pan gasket broken

Replace gasket

Front cover retaining bolts loose

or gasket broken

Retighten or replace gasket

Head cover retaining bolts loose

or gasket broken

Retighten or replace gasket

Oil filter adapter cracked

Replace

Oil filter attaching bolt loose or

rubber gasket broken

Retighten or replace oil filter

Crankshaft front or rear oil seal

defective

Replace oil seal

Oil pressure unit loose or broken

Retighten or replace

Blow-by gas hose broken

Replace hose

Engine/Transmission

coupling

area

Replace oil seal

Oil leaking into combustion

chambers due to poor seal in

valve system

Valve stem oil seal defective

Replace

Valve stem or valve guide worn

Replace valve and valve guide

Oil leaking into combustion

chambers due to poor seal in

cylinder parts

Cylinders and pistons worn

excessively

Rebore cylinder and replace

pistons and others

Piston ring gaps incorrectly

positioned

Correct

Piston rings set with wrong side

up

Correct

Piston rings sticking

Rebore cylinder and replace

pistons and others

Piston ring and ring groove worn

Replace pistons and others

Return ports in oil rings clogged

Clean piston and replace rings

Crank case ventilation, Positive

Crankcase Ventilation System

malfunctioning

Positive Crankcase Ventilation

Hose clogged

Clean

Others

Improper oil viscosity

Use oil of recommended S.A.E.

viscosity

Continuous high speed driving

and or severe usage such as

trailer towing

Continuous high speed operation

and or severe usage will normally

cause increased oil consumption