Isuzu KB P190. Manual - part 490

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-343

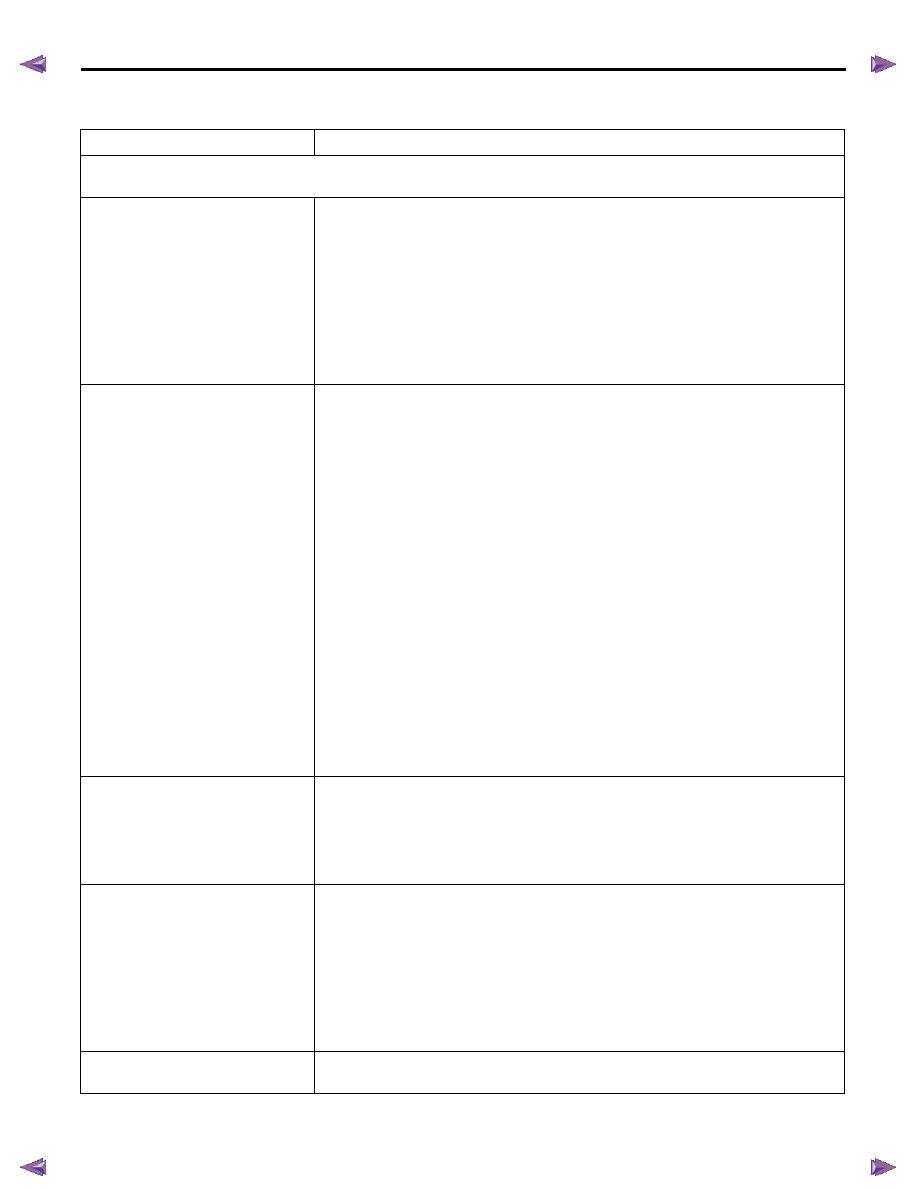

Excessive Smoke (Black Smoke)

Checks

Action

Definition:

Black smoke under load, idle or start up hot or cold.

Preliminary Check

• Ensure the vehicle has an actual problem.

• Inspect the ECM grounds for being clean, tight, and in their proper locations.

• Remove the air cleaner and check for dirt, or for air ducts being plugged or

restricted. Replace as necessary.

• Inspect the fuel quality (cetane index).

• Inspect the engine oil level and quality.

• Inspect the programmed fuel injector ID code for each cylinder.

• Inspect the Scan Tool Data List in this section.

• Inspect the Service Bulletin.

Sensor Checks

Inspect the engine control sensors for the following conditions. Refer to the Scan Tool

Data List in this section.

• Compare the Coolant Temperature with the Intake Air Temperature (IAT) and Fuel

Temperature (FT) parameters on a cold engine condition. If the difference among

temperature reading is more than 5

°C (9°F) on a cold engine, check for high

resistance in each circuit or for a skewed sensor.

Notice: The mass air flow (MAF) sensor is heated and as a result the IAT may indicate

a higher than normal intake air temperature if the ignition switch is being ON.

• Observe the MAF parameter for a skewed or slow MAF sensor.

• Observe the Fuel Rail Pressure (FRP) Sensor parameter with the engine OFF. The

FRP Sensor should read 0.9 to 1.0 volt with the key ON and engine OFF after the

engine has stopped running for a minimum of 1 minute. If not, check for high

resistance in each circuit or for a skewed sensor.

• Observe the Fuel Rail Pressure and Desired Fuel Rail Pressure parameter between

idle and W.O.T. (accelerator pedal full travel) in Neutral. Fuel Rail Pressure

parameter should follow within

±5 MPa (±725 psi) quick enough.

• Observe the Barometric Pressure (BARO) parameter. The BARO parameter should

indicate near surrounding barometric pressure. Refer to Altitude vs. Barometric

Pressure. (Standard output)

• Observe the Boost Pressure and BARO with ignition ON and engine OFF. Both

parameters should be within the 7.0 kPa (1.0 psi) each other. (High output)

Fuel System Checks

Inspect the fuel system for the following conditions. Refer to the Fuel System section.

• Fuel injectors. Remove the injectors and visually inspect.

• Perform the Cylinder Balance Test with a scan tool.

• Perform the Pilot Injection Control with a scan tool.

• Observe the Fuel Compensation for each cylinder at idle on the scan tool.

Air Intake System Checks

Inspect the air intake system for the following conditions.

• Air cleaner, air intake ducts and charge air cooler for a restriction, holes, or leaks.

• A restriction in the turbocharger inlet duct.

• Intake throttle valve for a stuck condition.

• A restriction or leak in the intake manifold.

• A restriction or damaged at MAF sensor.

• A worn or damaged turbocharger turbine wheel, shaft or compressor wheel. Refer

to turbocharger inspection in the Engine Mechanical section.

Exhaust System Checks

Inspect the exhaust system for a possible restriction. Refer to the Exhaust System

section.