Isuzu KB P190. Manual - part 466

ENGINE CONTROL SYSTEM (4JK1/4JJ1) 6E-247

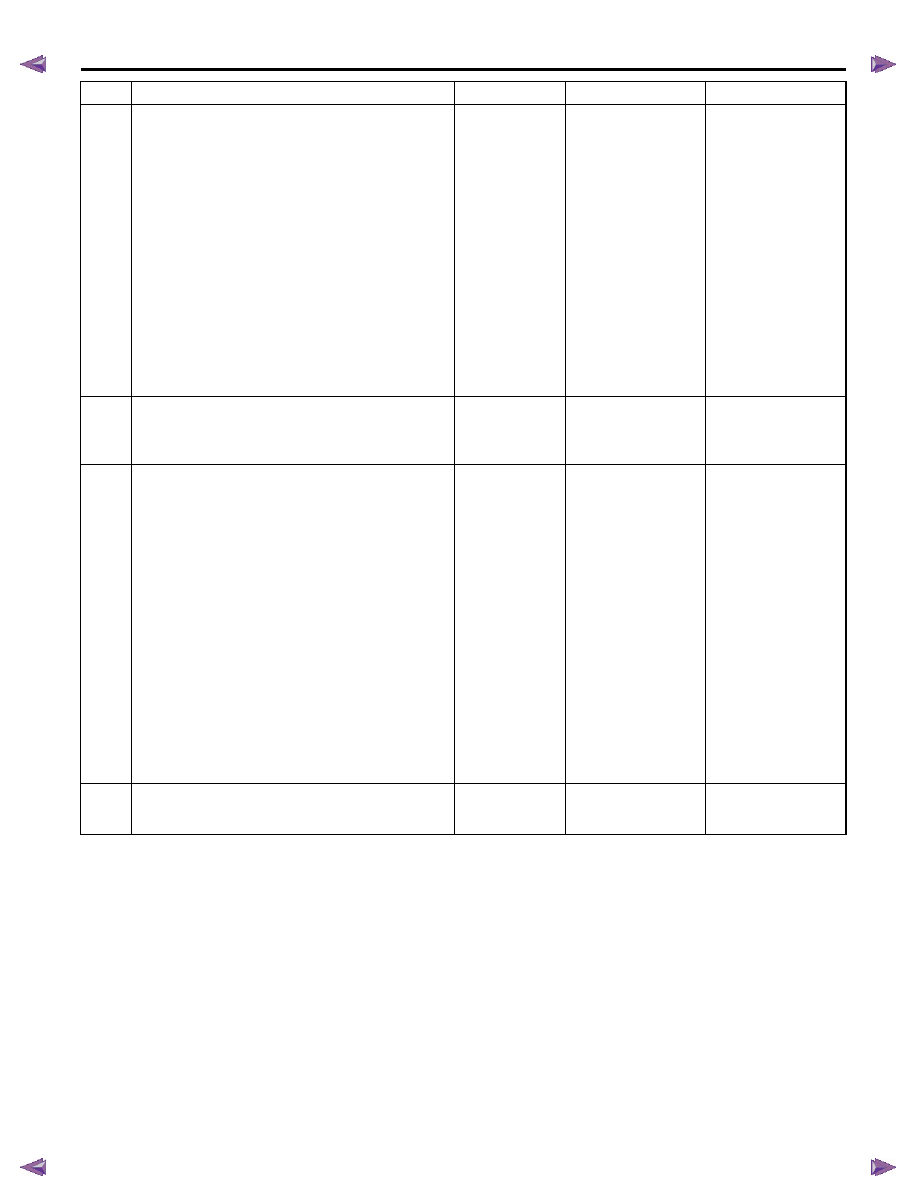

4

1.

Turn OFF the ignition.

2.

Disconnect the EGR valve harness connector.

3.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the EGR valve (pins 1, 2, 3, 4

and 6 of E-71).

4.

Disconnect the ECM harness connector.

5.

Inspect for an intermittent, for poor

connections and corrosion at the harness

connector of the ECM (pins 30, 31, 32, 62 and

63 of E-90).

6.

Test for high resistance on each circuit.

7.

Repair the connection(s) or circuit(s) as

necessary.

Did you find and correct the condition?

—

Go to Step 6

Go to Step 5

5

Replace the EGR valve. Refer to EGR Valve

Replacement.

Did you complete the replacement?

—

Go to Step 6

—

6

1.

Reconnect all previously disconnected

harness connector(s).

Notice: Ignition switch must be cycled before clear

the DTC.

2.

Turn ON the ignition, with the engine OFF.

3.

Turn OFF the ignition for 30 seconds.

4.

Turn ON the ignition and clear the DTCs with

a scan tool.

5.

Turn OFF the ignition for 30 seconds.

6.

Start the engine.

7.

Operate the vehicle within the Conditions for

Running the DTC. You may also operate the

vehicle within the conditions that you

observed from the Freeze Frame/ Failure

Records.

Did the DTC fail this ignition?

—

Go to Step 2

Go to Step 7

7

Observe the DTC Information with a scan tool.

Are there any DTCs that you have not diagnosed?

—

Go to DTC List

System OK

Step

Action

Value(s)

Yes

No