Isuzu KB P190. Manual - part 385

ENGINE COOLING (4JK1/4JJ1) 6B-17

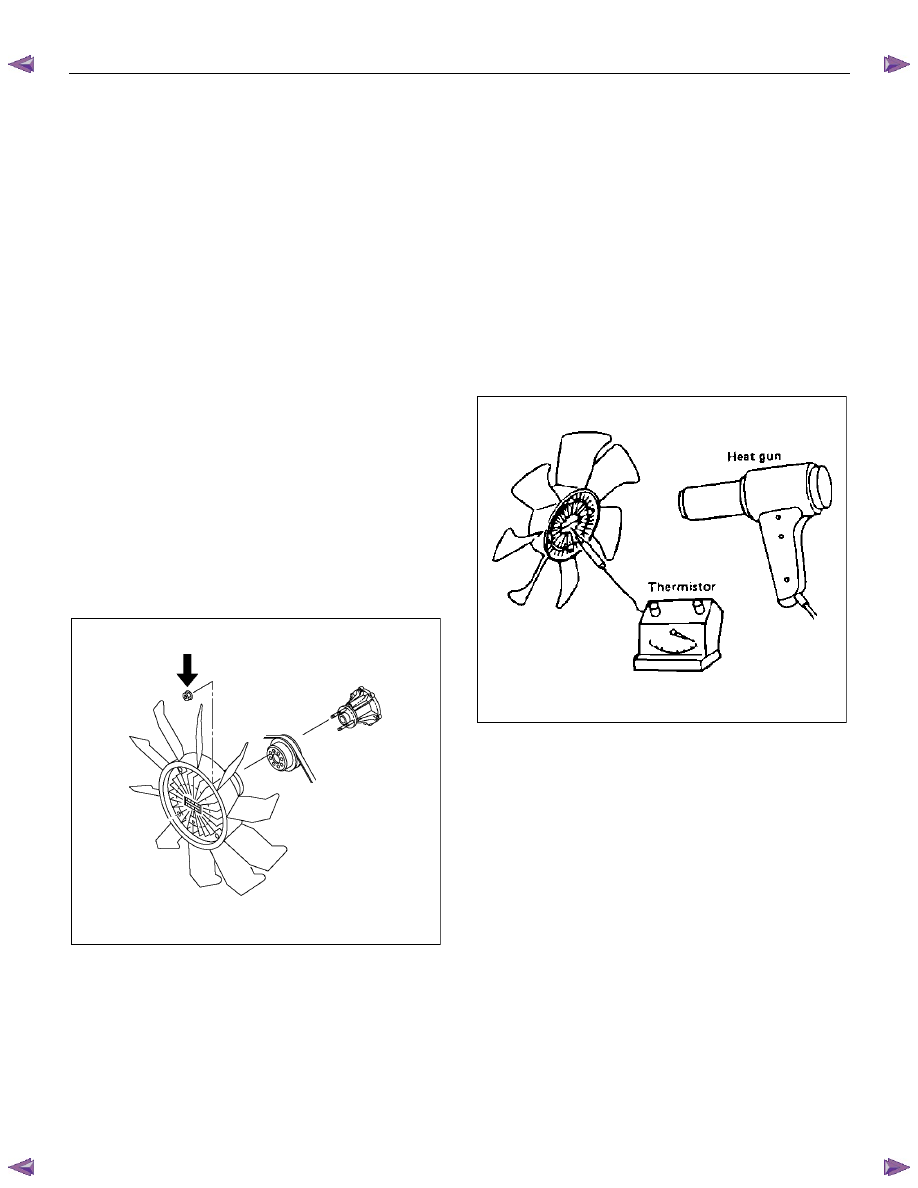

Fan Clutch with Cooling Fan

Inspection and Repair

Make necessary correction or parts replacement if

wear, damage or any other abnormal conditions are

found through inspection.

Visually inspect for damage, leak (silicon grease) or

other abnormal conditions.

1. Inspection (on-vehicle)

a) Turn the fan clutch by hand when in a low

temperature condition before starting the

engine, and confirm that it can be turned

readily.

b) Start the engine to warm it up until the

temperature at the fan clutch portion gets to

around 85°C (185°F). Then stop the engine and

confirm that the fan clutch can be turned with

considerable effort (clutch torque) when turned

by hand.

If the fan clutch rotates more readily, however,

this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

RTW56ASH025401

2. Inspection (in unit)

Warm up the bimetal of the fan clutch by using the

heat gun until the temperature gets to about 85°C

when measured with the thermistor. Then confirm

that the fan clutch can be turned with considerable

effort (clutch torque).

If the fan clutch rotates more readily at this time,

this indicates that the silicone grease is leaking

internally.

Replace the fan clutch with a new one.

033RY00011