Isuzu KB P190. Manual - part 368

6A-112 ENGINE MECHANICAL (4JK1/4JJ1)

RTW56ASH014201

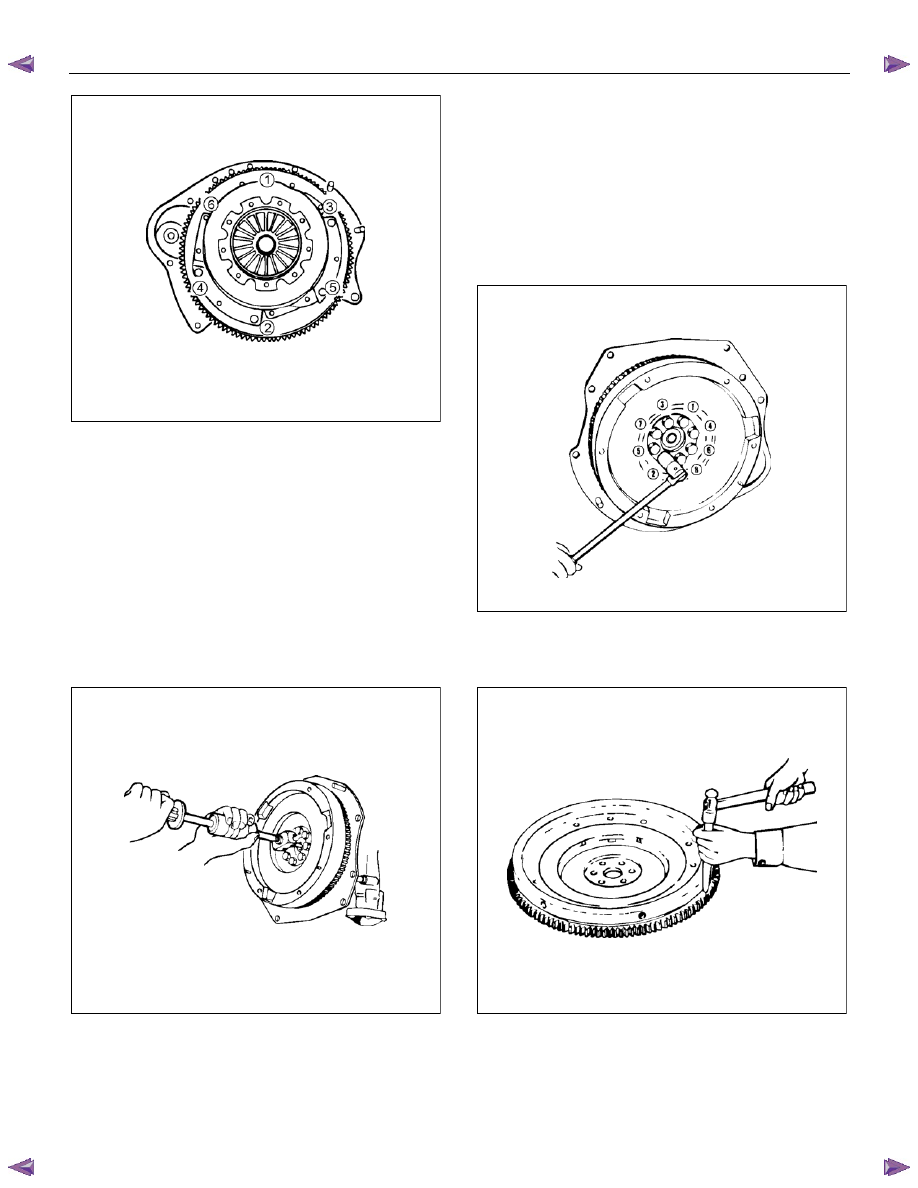

3. Remove the driven plate.

• Remove the driven plate from the flywheel

along with the clutch aligner.

• Install the crankshaft stopper in the starter

installation part of the rear plate.

Note:

Make sure that the stopper is applied with the ring gear

and installed properly.

Special

tool

Crankshaft stopper: 5-8840-0214-0

4. Remove the pilot bearing.

• Remove the pilot bearing from the flywheel.

015RY00018

Special

tool

Pilot Bearing Remover: 5-8840-2000-0

Sliding Hammer: 5-8840-0019-0

5. Remove the flywheel.

• Gradually loosen the flywheel installation bolts

in the order shown in the drawing so that the

flywheel does not rotate.

• After loosening the bolts, remove the stopper

and remove the flywheel.

• In the case of A/T car, after loosening the

flywheel installation bolts, remove the washer,

flexible plate, flywheel and sleeve in this order.

015RY00001

6. Remove the ring gear.

• Put a bar on the ring gear and hit it with a

hammer to remove it.

LNW21BSH012001