Isuzu KB P190. Manual - part 247

6C – 24 FUEL SYSTEM

13. Throttle Position Sensor Harness Connector

(4JA1TC/4JH1TC only)

Reconnect the harness connector to the throttle position

sensor.

14. Power Steering Pump Bracket

15. Fan

16. Vacuum Hose

Connect the vacuum hose to the EGR valve and the

intake throttle.

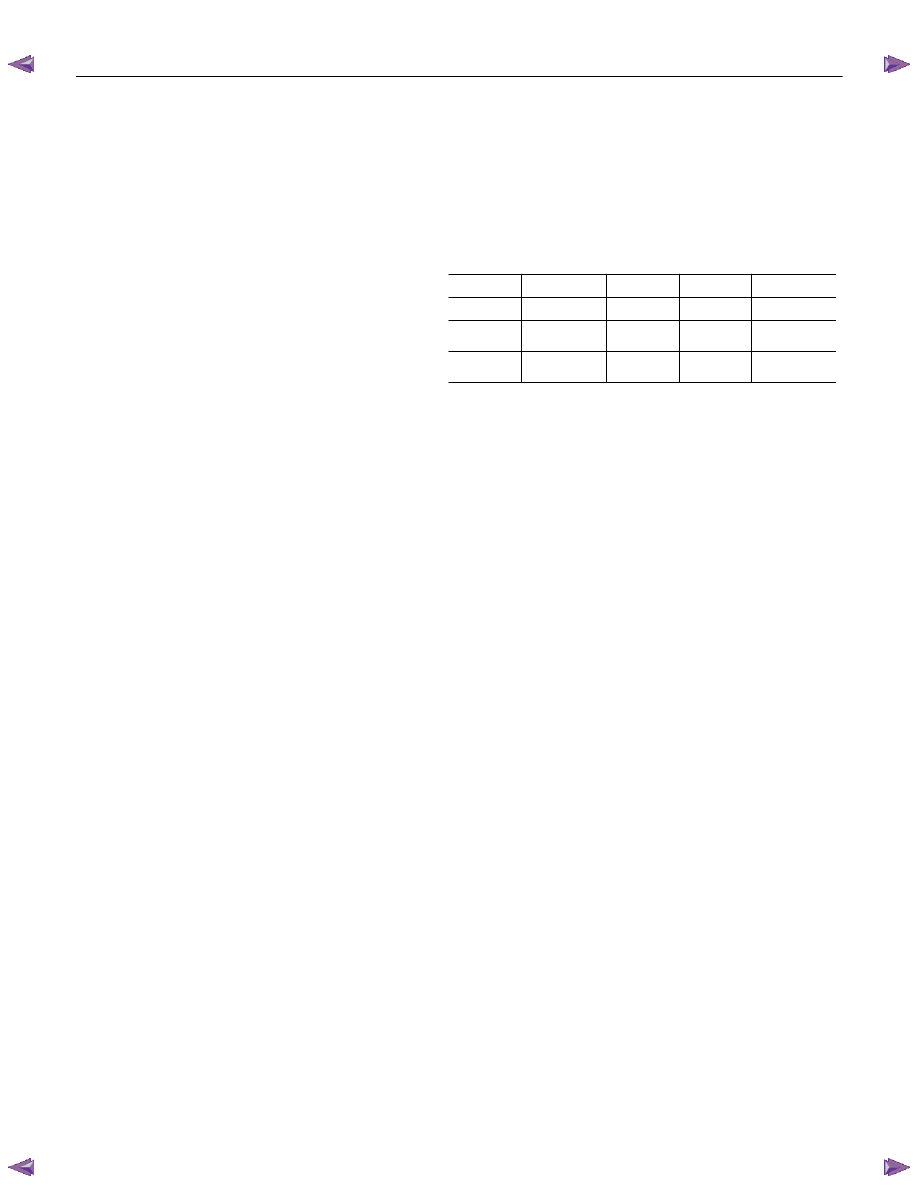

Euro under

Euro I

Euro II

Euro III

4JA1L without with with Not

used

4JA1TC

Not used

Not used

Not used

With cooler

(EGR cooler)

4JH1TC without

with

with

With

(EGR cooler)

17. Accelerator Control Cable

1) Connect the accelerator cable to the injection pump

(4JA1T) the intake throttle. (4JA1TC/4JH1TC only)

18. Power Steering Pump Assembly

19. Drive Belt

Install the drive belt and adjust the belt tension.

20. Battery