Isuzu KB P190. Manual - part 218

ENGINE MECHANICAL 6A – 67

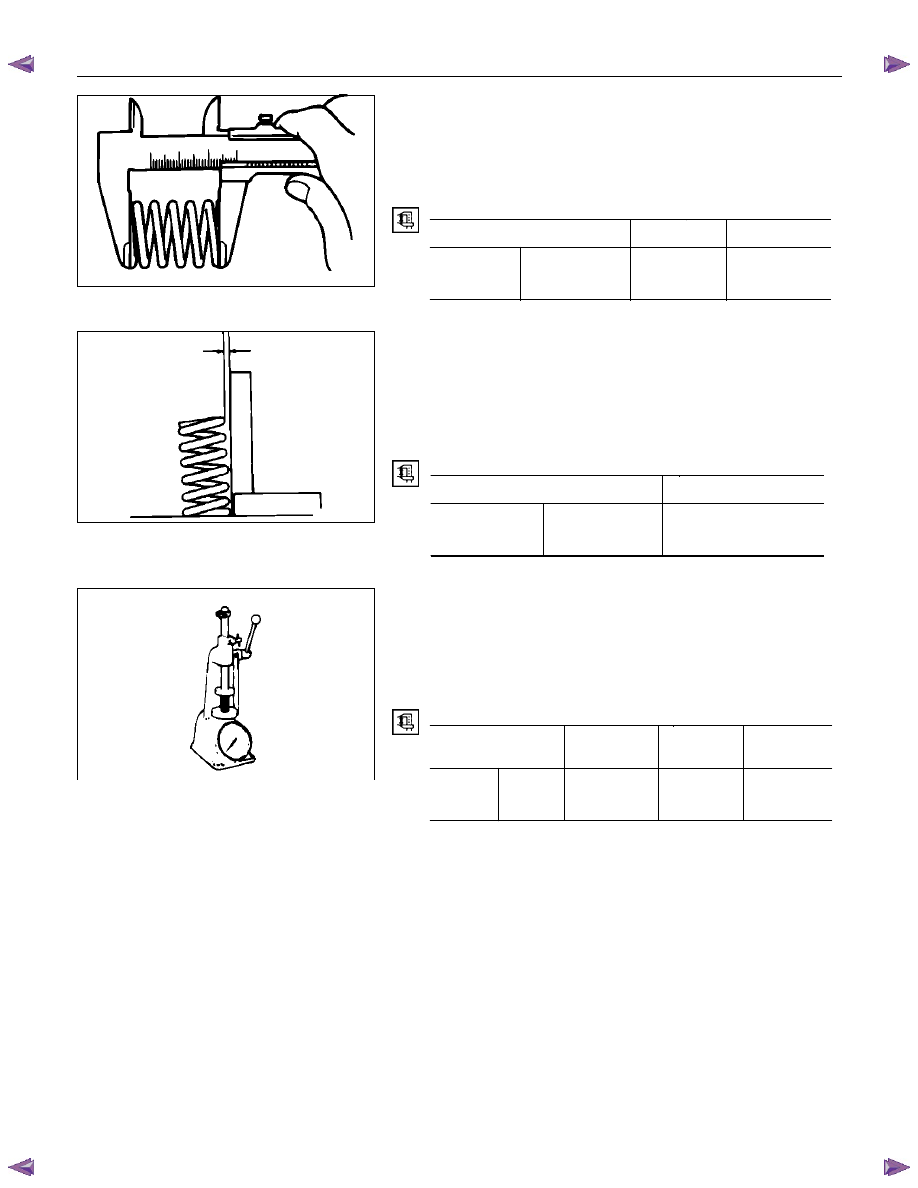

Valve Spring Free Height

Use a vernier caliper to measure the valve spring free height.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Spring Free Height

mm (in)

Standard

Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single spring

48.0 (1.89)

47.1 (1.85)

Valve Spring Squareness

Use a surface plate and a square to measure the valve spring

squareness.

If the measured value exceeds the specified limit, the valve

spring must be replaced.

Spring Squareness

mm (in)

Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single spring

1.7 (0.070)

Valve Spring Tension

Use a spring tester to measure the valve spring tension.

If the measured value is less than the specified limit, the valve

spring must be replaced.

Valve Spring Tension

N (kg/lb)

Compressed

Height

Standard Limit

4JA1T (L)

4JA1TC,

4JH1TC

Single

spring

38.9mm

(1.53in)

296.0

(30.2/66.4)

257.7

(26.3/57.9)

011LX024

014RY00025

011LX026