Infiniti QX56 (JA60). Manual - part 486

EM-98

< DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

• Remove oil and dust on the crankshaft pin and surfaces of each

bearing completely.

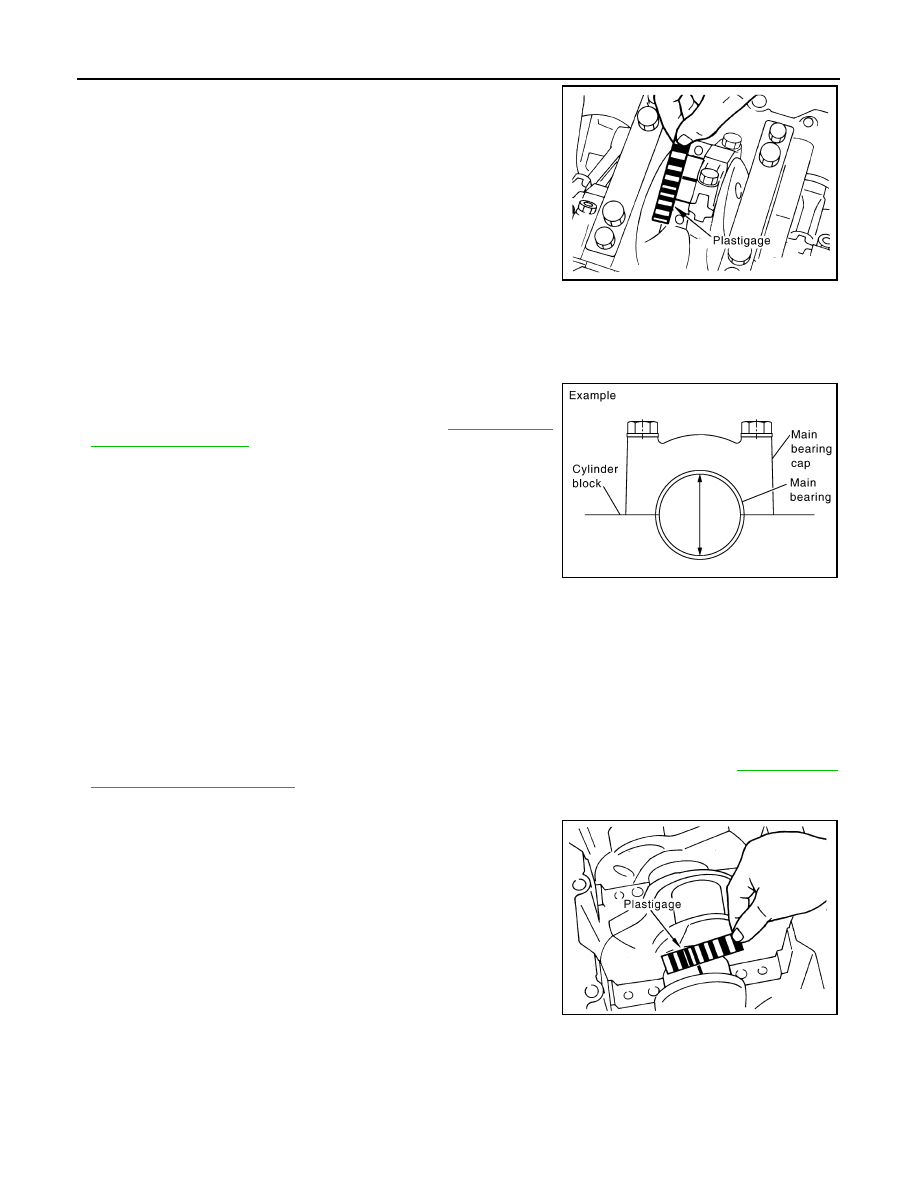

• Cut a plastigage slightly shorter than the bearing width, and place

it in the crankshaft axial direction, avoiding oil holes.

• Install the connecting rod bearings to the connecting rod and con-

necting rod bearing cap, and tighten the connecting rod bolts to the

specified torque.

CAUTION:

Do not rotate crankshaft with plastigage installed.

• Remove the connecting rod bearing cap and bearings. Measure

the plastigage width using the scale on the plastigage bag.

NOTE:

The procedure when the measured value exceeds the repair limit is the same as that described in “Method

of Measurement”.

MAIN BEARING OIL CLEARANCE

Method of Measurement

• Install the main bearings to the cylinder block and main bearing

cap. Measure the main bearing inside diameter with the bearing

cap bolts tightened to the specified torque. Refer to

.

(Oil clearance) = (Inside diameter of main bearing) – (Crankshaft

journal diameter)

• If measured value exceeds the repair limit, select main bearings referring to the main bearing inside diame-

ter and crankshaft journal diameter, so that the oil clearance satisfies the standard. Refer to

Method of Using Plastigage

• Remove oil and dust on the crankshaft journal and surfaces of

each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place

it in crankshaft axial direction, avoiding oil holes.

• Install the main bearings to the cylinder block and main bearing

cap, and tighten the main bearing bolts to the specified torque.

CAUTION:

Do not rotate crankshaft with plastigage installed.

• Remove bearing cap and bearings. Measure plastigage width

using the scale on the plastigage bag.

NOTE:

The procedure when the measured value exceeds the repair limit

is the same as that described in “Method of Measurement”.

CRUSH HEIGHT OF MAIN BEARING

KBIA2550E

Standard:

No. 1 and 5 journals

: 0.001 - 0.011 mm (0.00004 - 0.0004 in)

No. 2, 3 and 4 journals

: 0.007 - 0.017 mm (0.0003 - 0.0007 in)

Limit:

No.1 and 5 journals

: 0.021 mm (0.0008 in)

No. 2, 3 and 4 journals

: 0.027 mm (0.0011 in)

PBIC1644E

KBIA2551E