Infiniti QX56 (JA60). Manual - part 381

EC-176

< COMPONENT DIAGNOSIS >

[VK56DE]

P0171, P0174 FUEL INJECTION SYSTEM FUNCTION

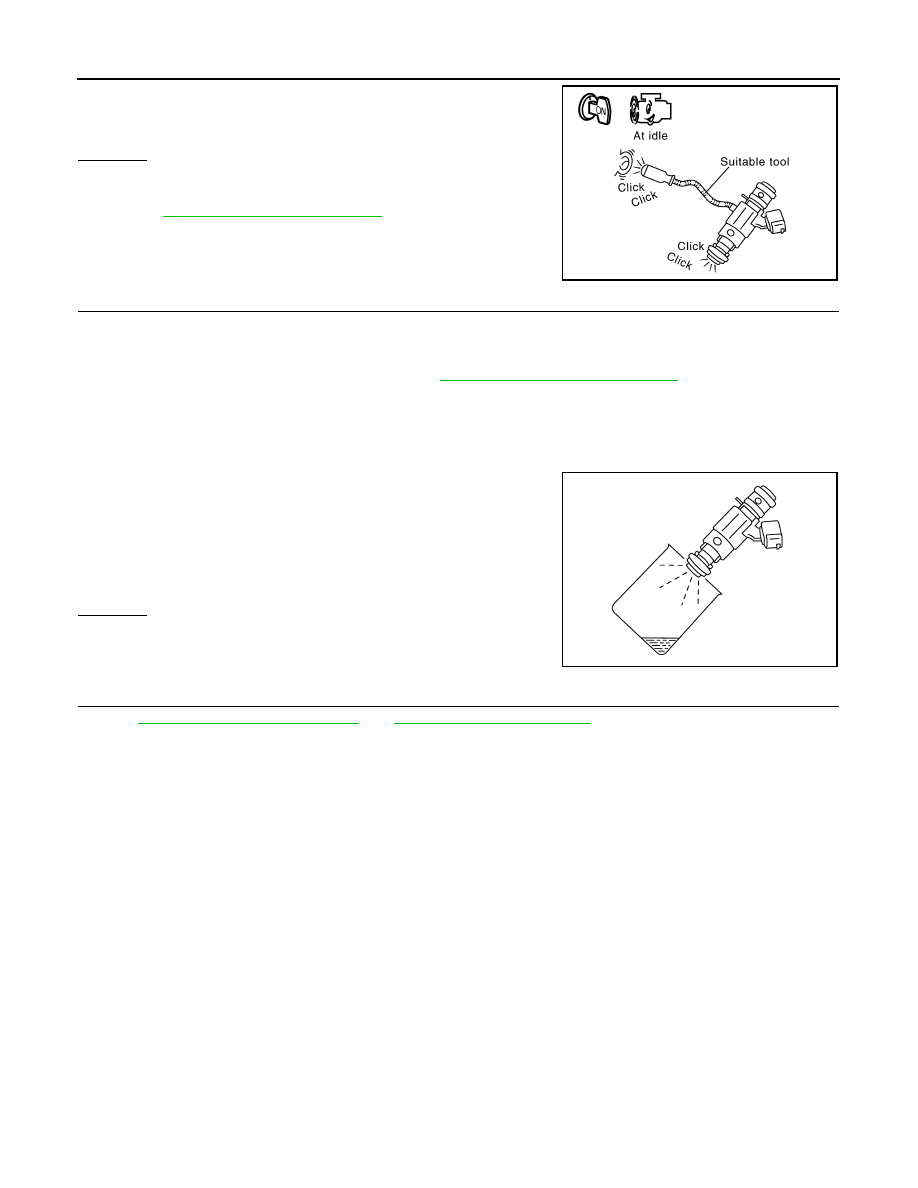

2. Listen to each fuel injector operating sound.

OK or NG

OK

>> GO TO 8.

NG

>> Perform trouble diagnosis for FUEL INJECTOR, refer to

.

8.

CHECK FUEL INJECTOR

1. Confirm that the engine is cooled down and there are no fire hazards near the vehicle.

2. Turn ignition switch OFF.

3. Disconnect all fuel injector harness connectors.

4. Remove fuel injector gallery assembly. Refer to

EM-40, "Removal and Installation"

Keep fuel hose and all fuel injectors connected to fuel injector gallery.

5. For DTC P0171, reconnect fuel injector harness connectors on bank 1.

For DTC P0174, reconnect fuel injector harness connectors on bank 2.

6. Disconnect all ignition coil harness connectors.

7. Prepare pans or saucers under each fuel injector.

8. Crank engine for about 3 seconds.

For DTC P0171, make sure that fuel sprays out from fuel injec-

tors on bank 1.

For DTC P0174, make sure that fuel sprays out from fuel injec-

tors on bank 2.

OK or NG

OK

>> GO TO 9.

NG

>> Replace fuel injectors from which fuel does not spray

out. Always replace O-ring with new ones.

9.

CHECK INTERMITTENT INCIDENT

GI-35, "How to Check Terminal"

and

GI-38, "Intermittent Incident"

>> INSPECTION END

Clicking noise should be heard.

PBIB1986E

Fuel should be sprayed evenly for each fuel injector.

PBIB1726E