Infiniti QX56 (Z62). Manual - part 922

ENGINE MAINTENANCE

MA-15

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

B

MA

N

O

A

12. Check cooling system for leakage with engine running.

13. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to

3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

• Sound may be noticeable at heater unit.

14. Repeat step 13 three times.

15. If sound is heard, bleed air from cooling system by repeating step 4, and steps from 6 to 14 until engine

coolant level no longer drops.

ENGINE COOLANT : Flushing

INFOID:0000000006394847

1.

Install reservoir tank if removed, and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring. Refer to

.

If water drain plug on cylinder block is removed, close and tighten it. Refer to

2.

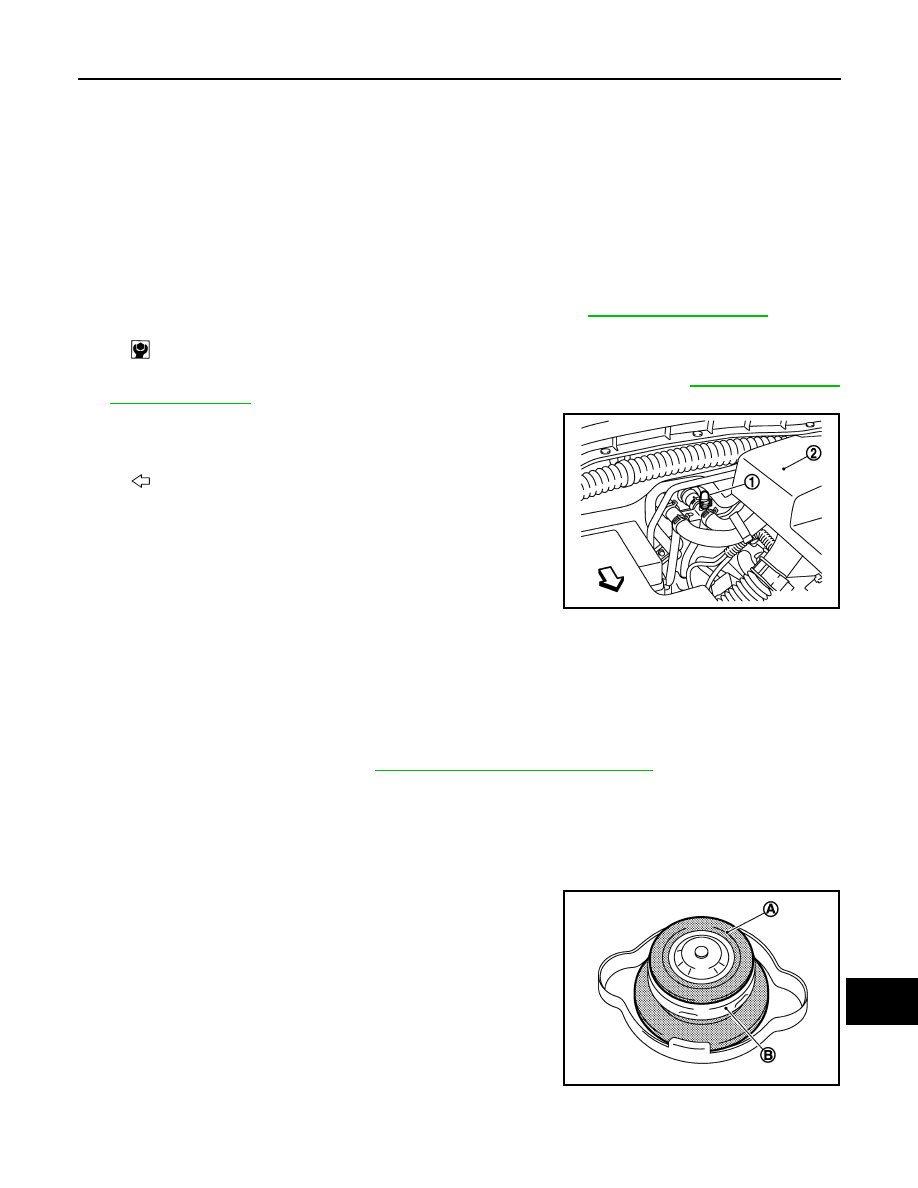

Remove air relief plug (1) on heater hose.

3.

Fill radiator and reservoir tank with water until water spills from the air relief holes, then close air relief

plugs with clamp. Fill radiator and reservoir tank with water and reinstall caps.

4.

Run the engine and warm it up to normal operating temperature.

5.

Rev the engine two or three times under no-load.

6.

Stop the engine and wait until it cools down.

7.

Drain water from the system. Refer to

MA-13, "ENGINE COOLANT : Draining"

.

8.

Repeat steps 1 through 7 until clear water begins to drain from radiator.

RESERVOIR TANK CAP

RESERVOIR TANK CAP : Inspection

INFOID:0000000006394848

• Check valve seat of reservoir tank cap.

- Check if valve seat (A) is swollen to the extent that the edge of the

metal plunger (B) cannot be seen when watching it vertically from

the top.

- Check if valve seat has no soil and damage.

: 1.96 N·m (0.2 kg-m, 17 in-lb)

2.

Engine cover

: Vehicle front

JPBIA3429ZZ

JPBIA0108ZZ