Infiniti M35/M45 Y50. Manual - part 910

ACTIVE AFS

LT-185

C

D

E

F

G

H

I

J

L

M

A

B

LT

CHECK HEIGHT SENSOR SIGNAL AND AIMING MOTOR DRIVE SIGNAL

Remove height sensor link bracket mounting nuts (rear stabilizer side). For details, refer to

and Installation of Height Sensor"

. Change sensor angle from the basic point of sensor angle 0

°

(standard

position) and check “HI SEN OTP RR” and “LEV ACTR VLTG” of “Data Monitor”.

With 18-inch wheel

NOTE:

1. Reference value. The value can be different from that of sensor angle and HI SEN OTP RR of maximum/minimum angle of auto

aiming operation depending on LEVELIZER ADJUSTMENT state.

2. Reference value. Approx.

−

1.5 V from the LEVELIZER ADJUSTMENT value.

With 19-inch wheel

NOTE:

1. Reference value. The value can be different from that of sensor angle and HI SEN OTP RR of maximum/minimum angle of auto

aiming operation depending on LEVELIZER ADJUSTMENT state.

2. Reference value. Approx.

−

1.2 V from LEVELIZER ADJUSTMENT value.

OK or NG

OK

>> Auto aiming operation function is normal.

NG

>>

●

When approx. 4.5 V or 0.5 V is not displayed on “HI SEN OTP RR” screen with sensor angle

approx. 45

°

or

−

45

°

, check connector for connection, bend and loose fit. If it is normal, replace

height sensor. Refer to

LT-193, "Removal and Installation of Height Sensor"

●

When “HI SEN OTP RR” value is normal but “LEV ACTR VLTG” value differs from maximum/

minimum angle of auto aiming operation, replace AFS control unit. Refer to

and Installation of AFS Control Unit"

●

When “LEV ACTR VLTG” value is normal but operation range is irregular, check aiming motor

system circuit. Refer to

LT-188, "Auto Aiming Does Not Operate (Check Aiming Motor System

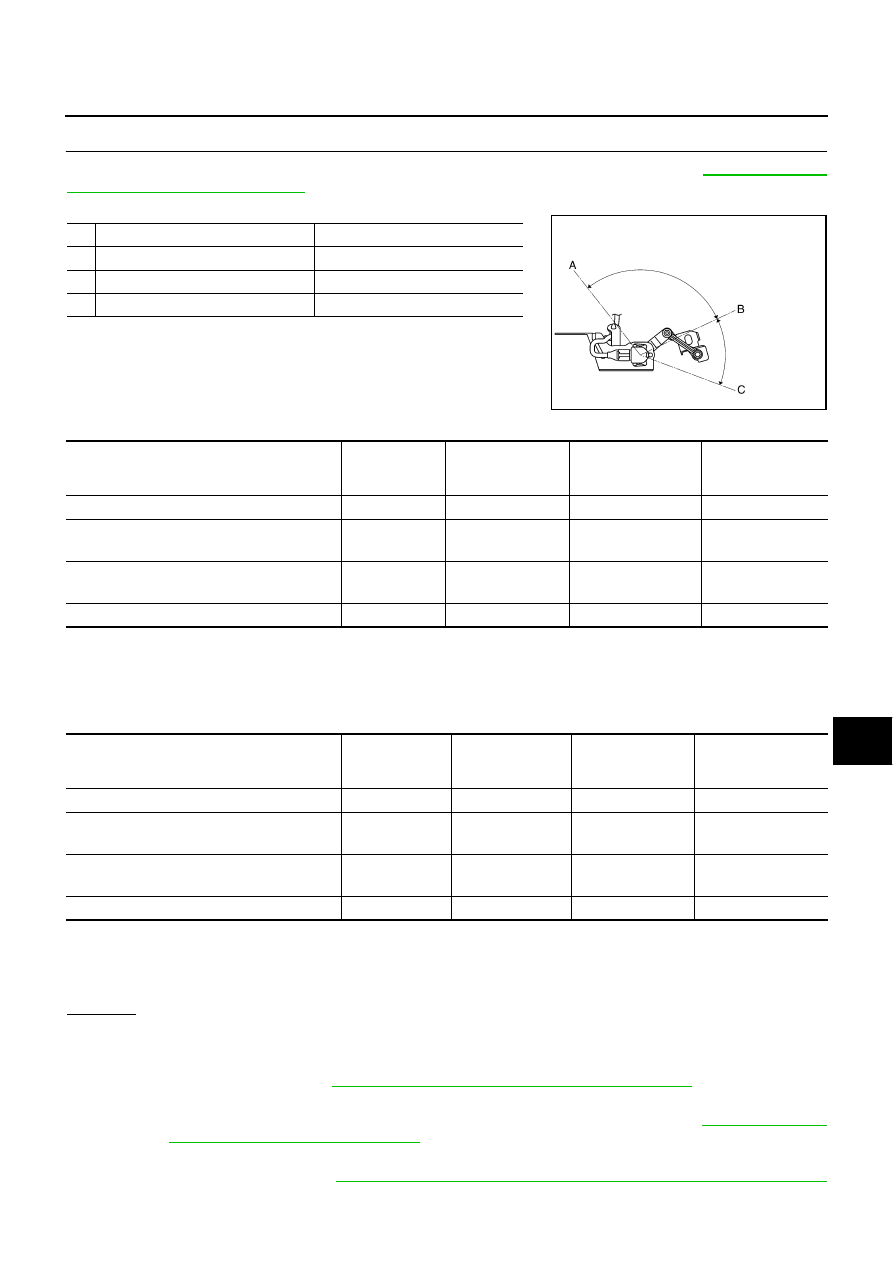

Sensor angle

Vehicle height

A

Approx. –103

°

(Link stopper angle)

Low side

B

0

°

(Standard position)

Unloaded vehicle position

C

Approx. 46

°

(Link stopper angle)

High side

SKIB4689E

Sensor angle

“HI SEN OTP RR”

“LEV ACTR VLTG”

Light axis range at

10 m (394.7 in) off

(Reference value)

Limit value of vehicle height (high side)

Approx. 45

°

Approx. 4.5 V

Approx. 70.0%

—

Maximum angle of auto aiming operation

NOTE1

(Unloaded vehicle position)

Approx. 0

°

Approx. 2.5 V

Approx. 70.0%

0

Minimum angle of auto aiming operation

NOTE1

(Maximum laden condition)

Approx.

−

35

°

Approx. 1.0 V

NOTE2

Approx. 38.0%

Approx. 200 mm

(7.9 in)

Limit value of vehicle height (low side)

Approx.

−

45

°

Approx. 0.5 V

Approx. 38.0%

—

Sensor angle

“HI SEN OTP RR”

“LEV ACTR VLTG”

Light axis range at

10m (394.7 in) off

(Reference value)

Limit value of vehicle height (high side)

Approx. 45

°

Approx. 4.5 V

Approx. 70.0%

—

Maximum angle of auto aiming operation

NOTE1

(Unloaded vehicle position)

Approx. 0

°

Approx. 2.5 V

Approx. 70.0%

0

Minimum angle of auto aiming operation

NOTE1

(Maximum laden condition)

Approx.

−

27

°

Approx. 1.3

NOTE2

Approx. 41.8%

Approx. 180 mm

(7.1 in)

Limit value of vehicle height (low side)

Approx.

−

45

°

Approx. 0.5 V

Approx. 41.8%

—