Infiniti M35/M45 Y50. Manual - part 540

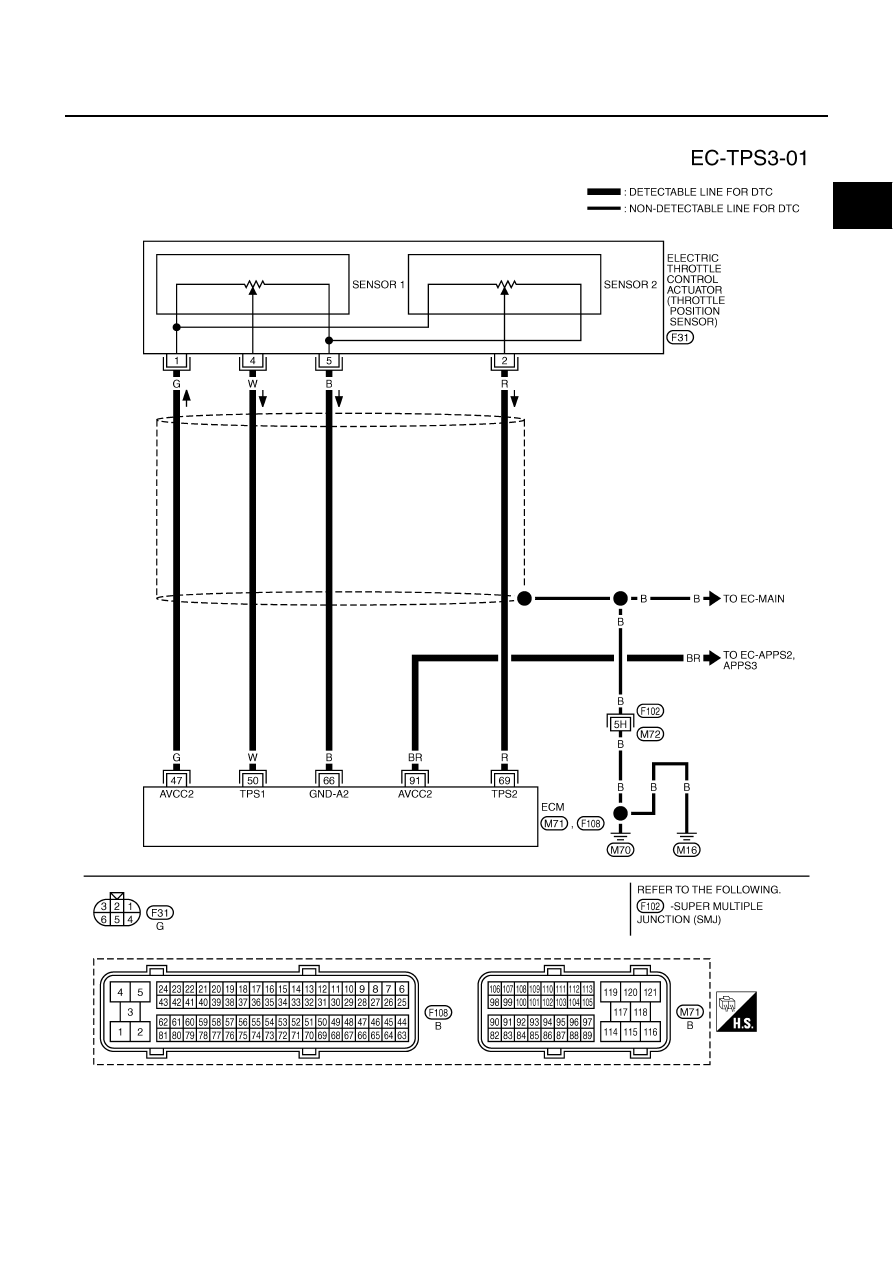

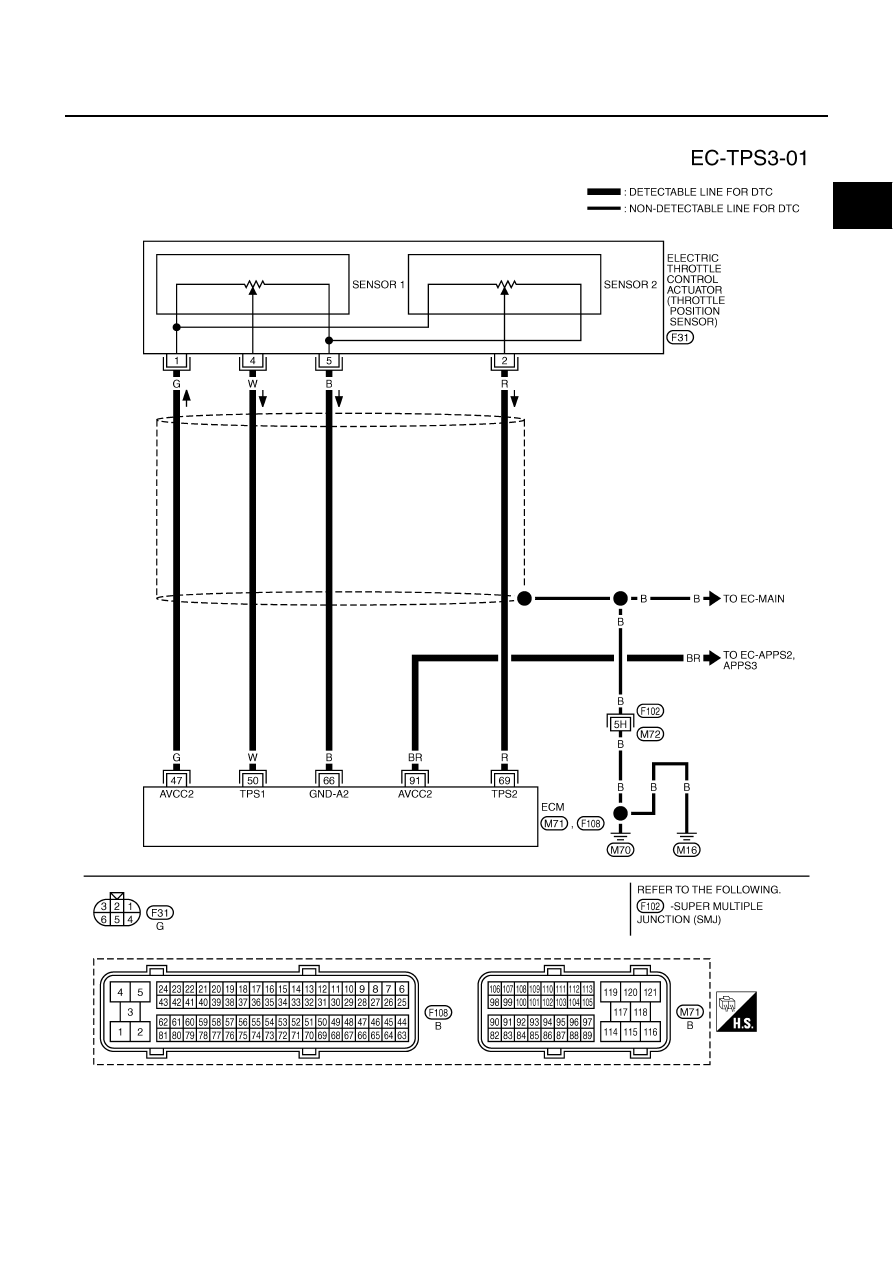

DTC P2135 TP SENSOR

EC-633

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

Wiring Diagram

NBS00575

TBWT1483E

|

|

|

DTC P2135 TP SENSOR EC-633 [VQ35DE] C D E F G H I J K L M A EC Wiring Diagram NBS00575 TBWT1483E |