Infiniti F50. Manual - part 715

WHEEL HUB

RAX-5

C

E

F

G

H

I

J

K

L

M

A

B

RAX

WHEEL HUB

PFP:43202

On-Vehicle Inspection and Service

EDS000WN

Check that the mounting conditions (looseness, back lash) of each component and component status (wear,

damage) are normal.

WHEEL BEARING INSPECTION

●

Move wheel hub in the axial direction by hand. Check that there is no looseness of wheel bearings.

●

Rotate wheel hub and check that there is no unusual noise or other irregular conditions. If there are any

irregular conditions, replace wheel bearings.

Removal and Installation

EDS000WO

REMOVAL

1.

Remove tire with power tool.

2.

Remove cotter pin. Then remove lock nut from drive shaft.

3.

Remove brake caliper with power tool. Hang it in a place where it will not interfere with work. Refer to

CAUTION:

Avoid depressing brake pedal while brake caliper is removed.

4.

Remove disc rotor and remove parking cable and parking brake shoe from back plate. Refer to

5.

Remove fixing bolts and nuts in axle side of radius rod, front lower link.

6.

Remove fixing bolt and nut in axle side of rear lower link. Then remove coil spring. Refer to

"REAR LOWER LINK & COIL SPRING"

7.

Remove fixing bolt and nut in axle side of shock absorber.

8.

Using a puller (suitable tool), remove axle from drive shaft.

CAUTION:

●

When removing axle, do not apply an excessive angle to drive shaft joint. Also be careful not to

excessively extend slide joint.

Standard value

Axial end play

: 0.05 mm (0.002 in) or less

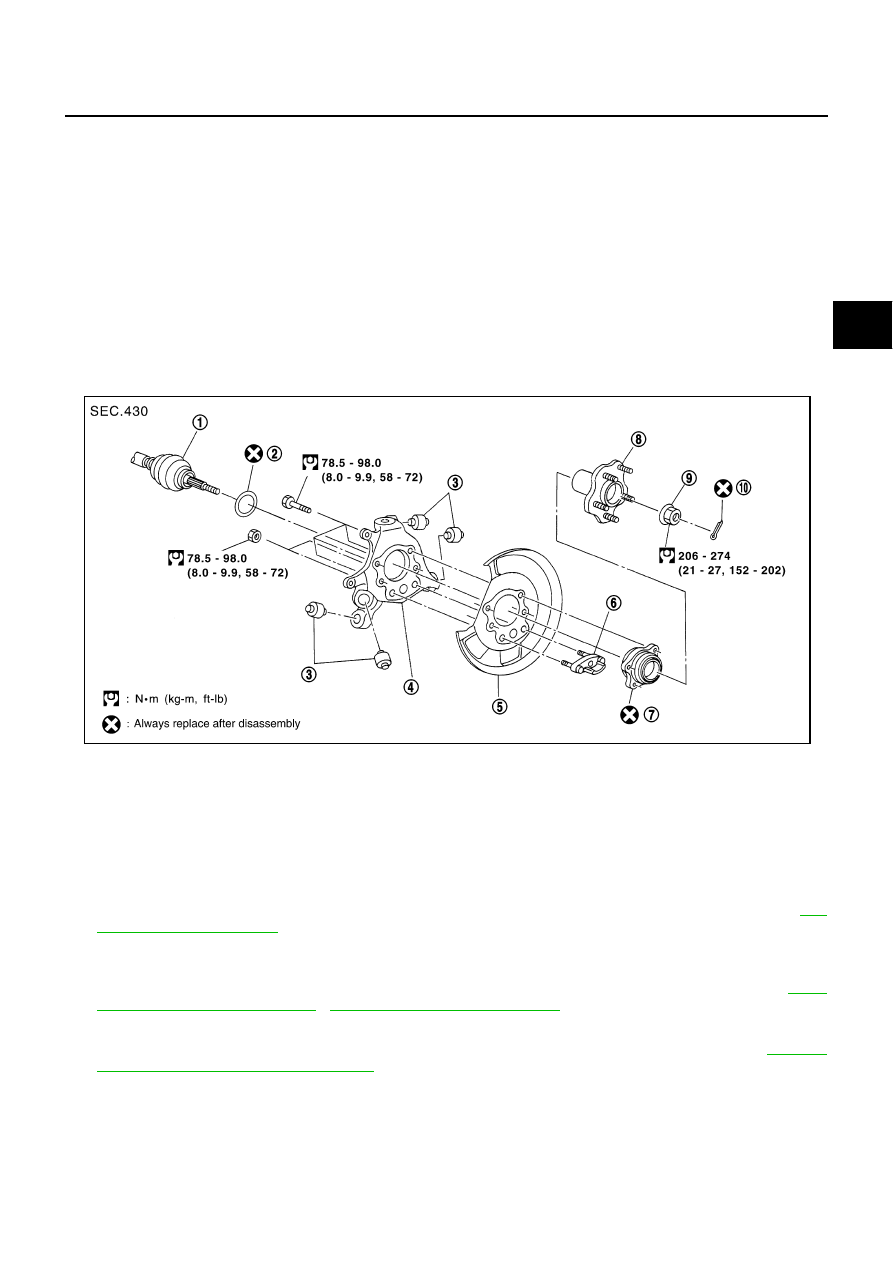

1.

Drive shaft

2.

Dust shield

3.

Bushing

4.

Axle

5.

Back plate

6.

Anchor block

7.

Wheel bearing

8.

Wheel hub

9.

Lock nut

10. Cotter pin

SDIA1164E