Infiniti F50. Manual - part 534

EXHAUST MANIFOLD AND THREE WAY CATALYST

EM-23

C

D

E

F

G

H

I

J

K

L

M

A

EM

e.

Remove exhaust manifold cover.

f.

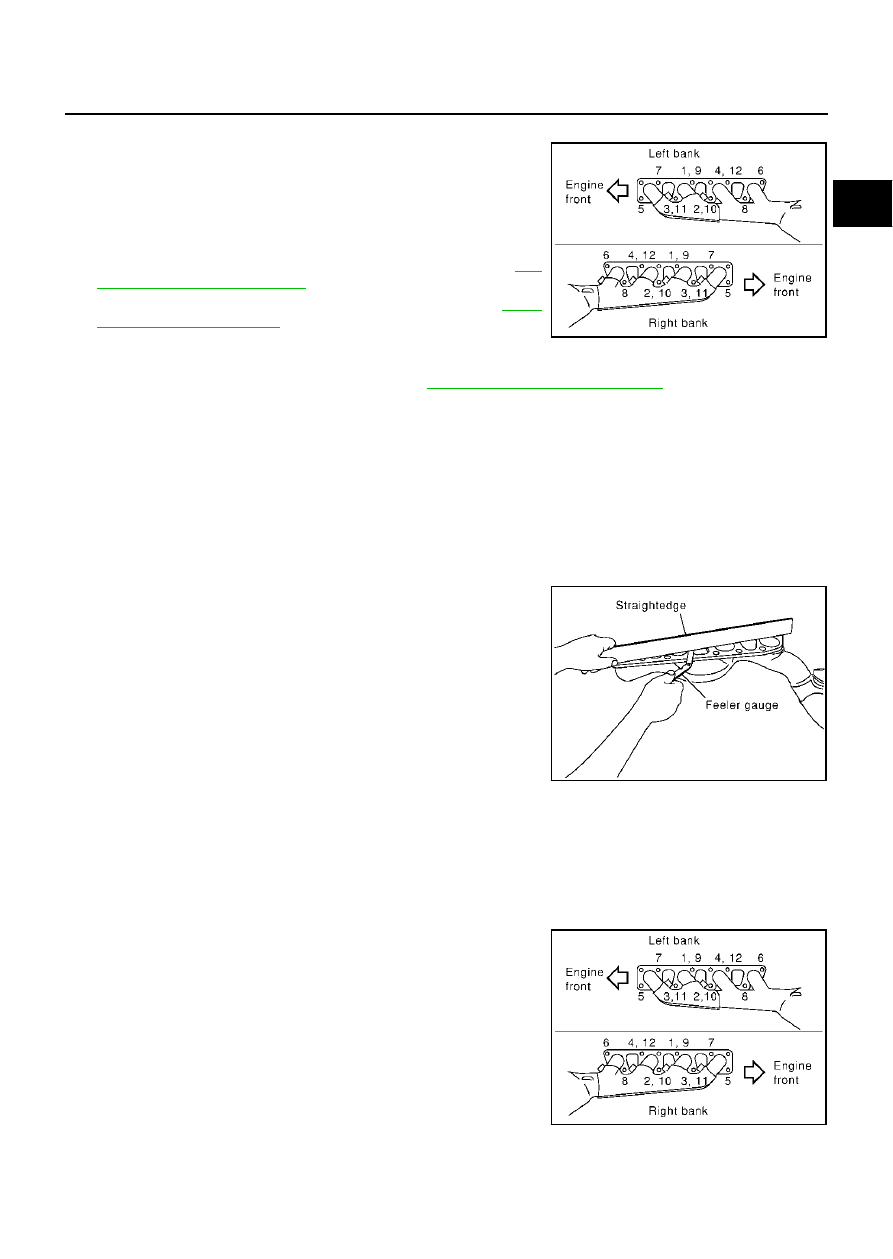

Loosen nuts in reverse order of illustration to remove exhaust

manifold and three way catalyst.

CAUTION:

Disregard the numerical order No.9 to 12 in removal.

3.

Remove exhaust manifold and three way catalyst (right bank)

loosening nuts in reverse order in the figure.

a.

Remove drive belt and alternator with power tool. Refer to

19, "Removal and Installation"

.

b.

Remove exhaust front tube with power tool. Refer to

c.

Remove nuts on bottom of right engine mounting insulator, and

lift up right side of engine approximately 3 cm (1.18 in) with transmission jack.

d.

Remove starter motor with power tool. Refer to

SC-28, "Removal and Installation"

e.

Support and lift up bottom of engine with transmission jack. Remove right engine mount insulator along

with right engine mount brackets.

f.

Remove exhaust manifold cover.

g.

Loosen nuts in reverse order of illustration to remove exhaust manifold and three way catalyst with power

tool.

CAUTION:

Disregard the numerical order No.9 to 12 in removal.

INSPECTION AFTER REMOVAL

Surface Distortion

Use a reliable straightedge and feeler gauge to check the flatness of

each exhaust manifold flange surface.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

Exhaust Manifold Gasket

Install exhaust manifold gasket with its directional protrusion set upward. Refer to illustration of components

on former page.

Tightening Exhaust Manifold Nuts

●

Install exhaust manifold and three way catalyst in the numerical

order shown in the figure.

●

Tighten nuts No.1 to No.4 in two steps. Order No.9 to 12 shows

second step.

PBIC0022E

Limit

: 0.3mm (0.012in)

PBIC0023E

PBIC0022E