Infiniti G37 Coupe. Manual - part 426

DLN-18

< SERVICE DATA AND SPECIFICATIONS (SDS)

[REAR PROPELLER SHAFT: 3S80A-R]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

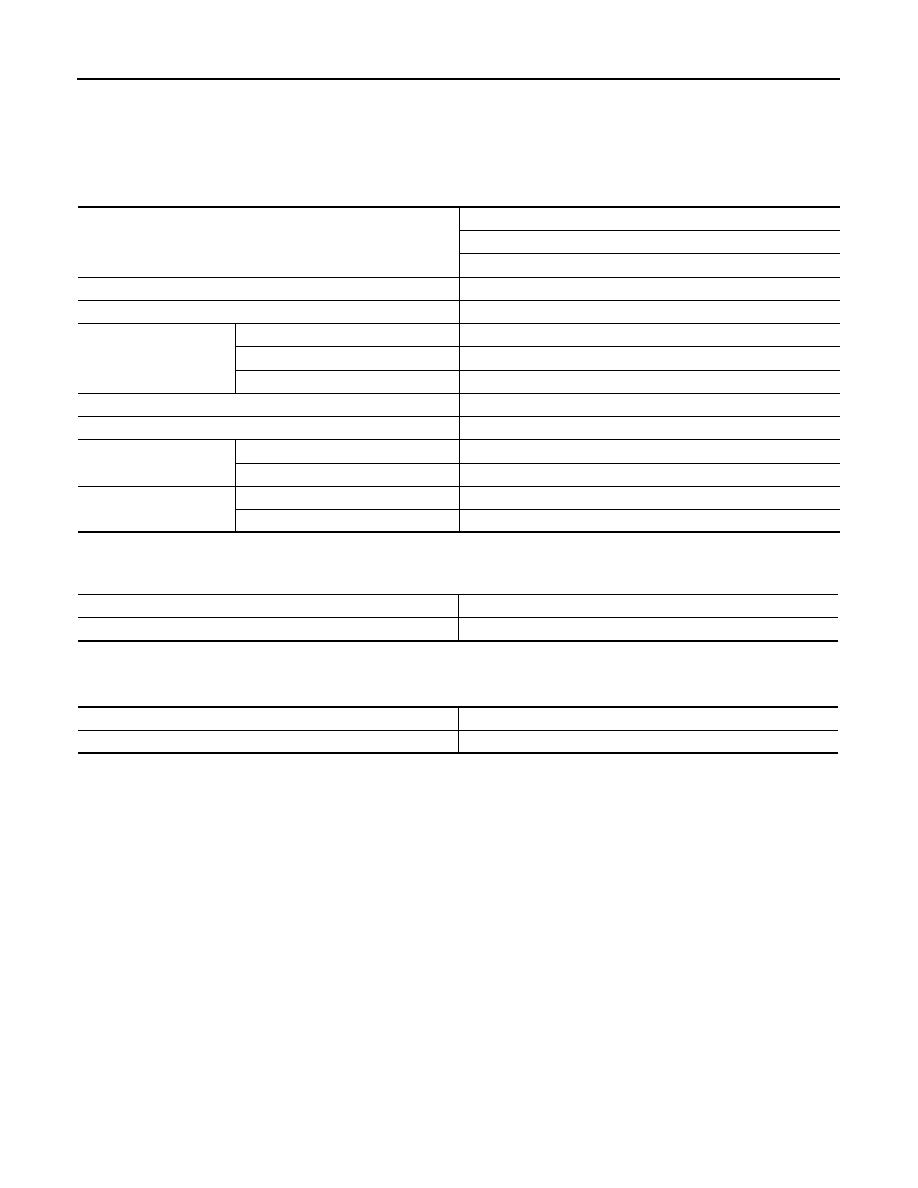

General Specifications

INFOID:0000000001714158

Propeller Shaft Runout

INFOID:0000000001714159

Unit: mm (in)

Journal Axial Play

INFOID:0000000001714160

Unit: mm (in)

Applied model

2WD

VQ37VHR

A/T

Propeller shaft model

3S80A-R

Number of joints

3

Type of journal bearings

(Non-disassembly type)

1st joint

Shell type

2nd joint

Shell type

3rd joint

Rubber coupling type

Coupling method with transmission

Sleeve type

Coupling method with rear final drive

Rubber coupling type

Shaft length

1st (Spider to spider)

724 mm (28.50 in)

2nd (Spider to rubber coupling center)

769 mm (30.28 in)

Shaft outer diameter

1st

82.6 mm (3.25 in)

2nd

75.0 mm (2.95 in)

Item

Limit

Propeller shaft runout

0.8 (0.031)

Item

Standard

Journal axial play

0 (0)