Content .. 1300 1301 1302 1303 ..

Infiniti G37 Coupe. Manual - part 1302

MAINSHAFT AND GEAR

TM-61

< DISASSEMBLY AND ASSEMBLY >

[6MT: FS6R31A]

C

E

F

G

H

I

J

K

L

M

A

B

TM

N

O

P

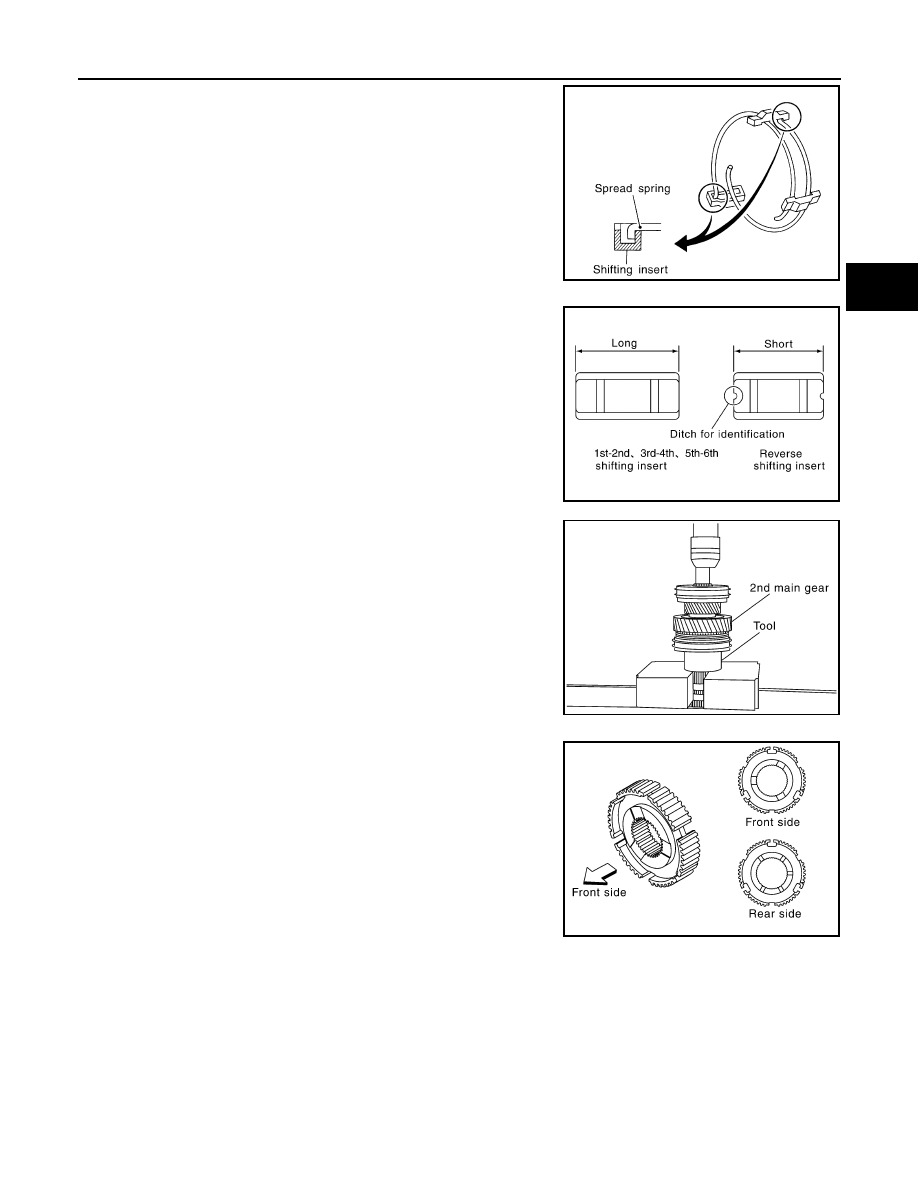

• Never install 1st-2nd spread spring hook onto the same

1st-2nd shifting insert.

• Be careful with the shape of reverse shifting insert to

avoid misassembly.

8.

Apply recommended grease to 2nd needle bearing.

9.

Install 2nd main gear, 2nd needle bearing, 2nd inner baulk ring,

2nd synchronizer cone and 2nd outer baulk ring on mainshaft

and then using a support ring [SST: ST27861000 (

—

)] and

a press to press fit 1st-2nd synchronizer assembly.

CAUTION:

• Replace 2nd inner baulk ring, 2nd synchronizer cone and

2nd outer baulk ring as a set.

• When press fitting, install with the side having the three

boss edge oil grooves facing the front side.

NOTE:

SCIA1600E

PCIB0608E

PCIB0202E

PCIB1364E