Infiniti G35 (V35) Sedan. Manual - part 750

HA-34

< ON-VEHICLE MAINTENANCE >

REFRIGERATION SYSTEM

Testing must be performed as follows:

TEST READING

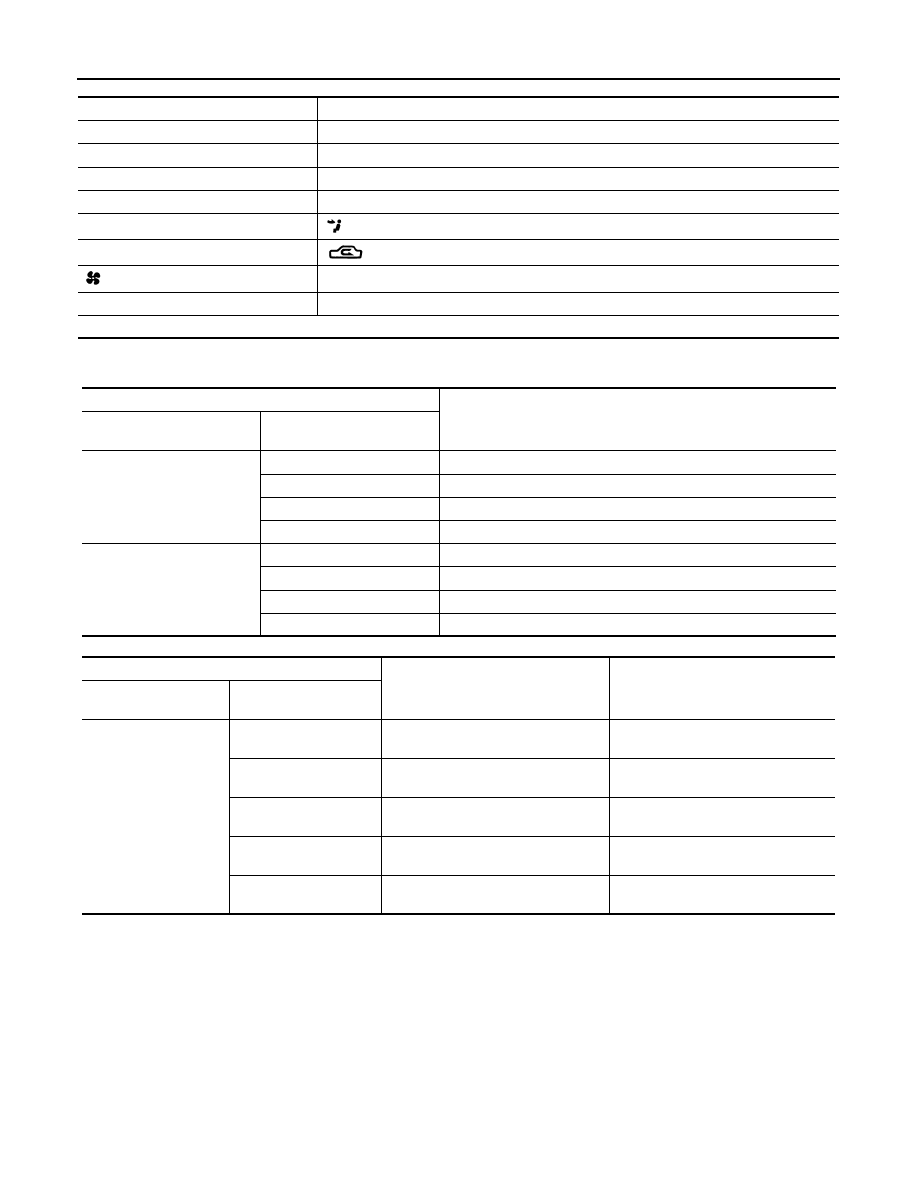

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Refrigerant Leaks

INFOID:0000000000959864

Perform a visual inspection of all refrigeration parts, fittings, hoses and components for signs of A/C lubricant

leakage, damage and corrosion. A/C lubricant leakage may indicate an area of refrigerant leakage. Allow

extra inspection time in these areas when using either an electrical leak detector or fluorescent dye leak

detector (SST: J-42220).

If dye is observed, confirm the leak with an electrical leak detector. It is possible a prior leak was repaired and

not properly cleaned.

When searching for leaks, do not stop when one leak is found but continue to check for additional leaks at all

system components and connections.

When searching for refrigerant leaks using an electrical leak detector, move the probe along the suspected

leak area at 1 to 2 inches per second and no further than 1/4 inch from the component.

Vehicle condition

Indoors or in the shade (in a well-ventilated place)

Doors

Closed

Door windows

Open

Hood

Open

TEMP.

Max. COLD

Mode switch

(Ventilation) set

Intake switch

(Recirculation) set

Fan (blower) speed

Max. speed set

Engine speed

Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°

C (

°

F)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 60

20 (68)

6.3 - 7.9 (43 - 46)

25 (77)

10.6 - 12.8 (51 - 55)

30 (86)

14.8 - 17.6 (59 - 64)

35 (95)

19.0 - 22.3 (66 - 72)

60 - 70

20 (68)

7.9 - 9.4 (46 - 49)

25 (77)

12.8 - 14.9 (55 - 59)

30 (86)

17.6 - 20.3 (64 - 69)

35 (95)

22.3 - 25.7 (72 - 78)

Ambient air

High-pressure (Discharge side)

kPa (kg/cm

2

, psi)

Low-pressure (Suction side)

kPa (kg/cm

2

, psi)

Relative humidity

%

Air temperature

°

C (

°

F)

50 - 70

20 (68)

768 - 940

(7.8 - 9.6, 111.4 - 136.3)

180 - 220

(1.8 - 2.2, 26.1 - 31.9)

25 (77)

925 - 1,131

(9.4 - 11.5, 134.1 - 164.0)

218 - 267

(2.2 - 2.7, 31.6 - 38.7)

30 (86)

1,082 - 1,322

(11.0 - 13.5, 156.9 - 191.7)

258 - 314

(2.6 - 3.2, 37.4 - 45.5)

35 (95)

1,238 - 1,513

(12.6 - 15.4, 179.5 - 219.4)

296 - 362

(3.0 - 3.7, 42.9 - 52.5)

40 (104)

1,395 - 1,704

(14.2 - 17.4, 202.3 - 247.1)

335 - 408

(3.4 - 4.2, 48.6 - 59.2)