Infiniti G35 (V35) Sedan. Manual - part 707

FAX-28

< SERVICE DATA AND SPECIFICATIONS (SDS)

[AWD]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

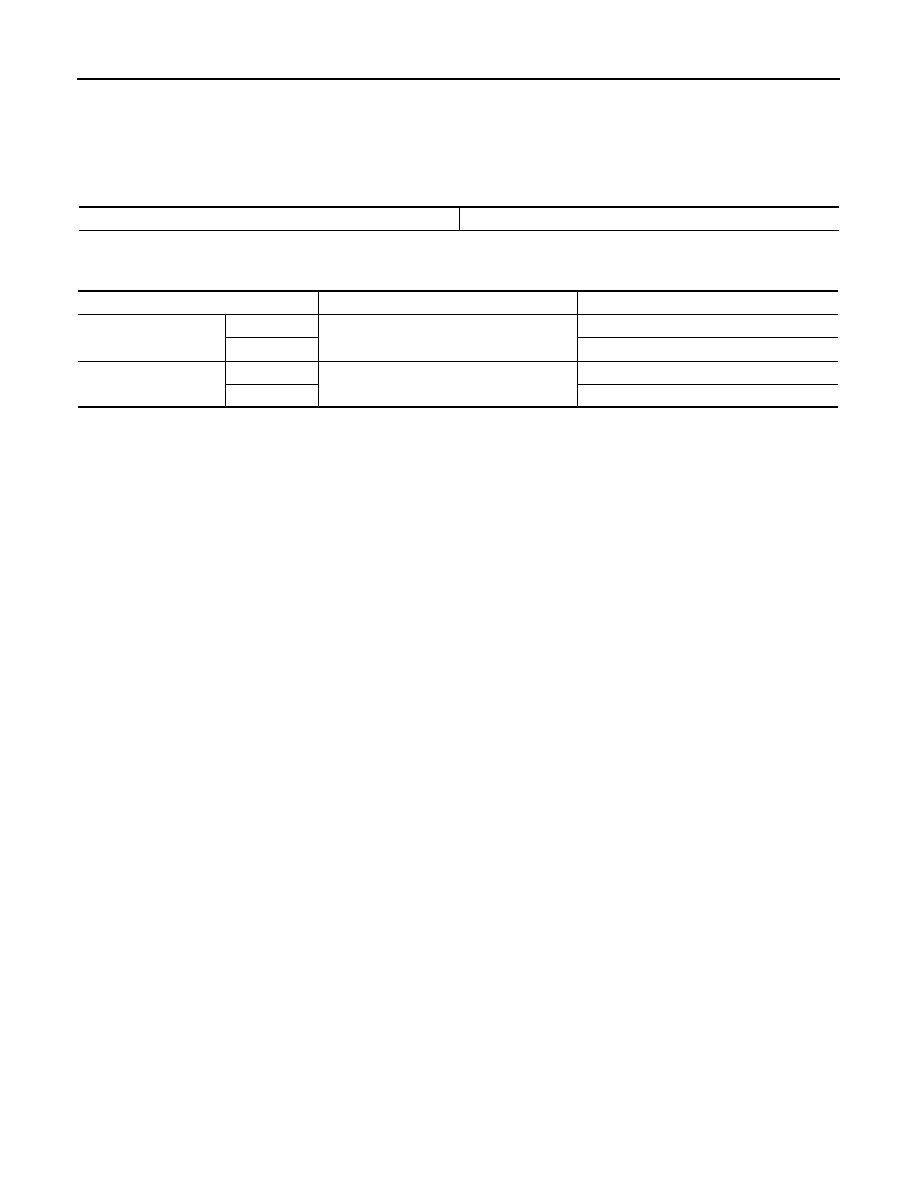

Wheel Bearing

INFOID:0000000000957496

Drive Shaft

INFOID:0000000000957497

Axial end play

0.05 mm (0.002 in) or less

Joint

Wheel side

Front final drive side

Grease quantity

Left side

77 – 97 g (2.72 – 3.42 oz)

95 – 105 g (3.35 – 3.70 oz)

Right side

113 – 123 g (3.99 – 4.34 oz)

Boots installed length

Left side

136 mm (5.35 in)

151.9 mm (5.98 in)

Right side

158 mm (6.22 in)